Antibacterial collagen preparation method based on epoxidation modification of safrole

A technology of safrole and epoxidation, which is applied in the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of continuous dissolution antibacterial mode, lack of long-term effect, and affect the biocompatibility of natural collagen, etc., to achieve antibacterial The effect of long-lasting function and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

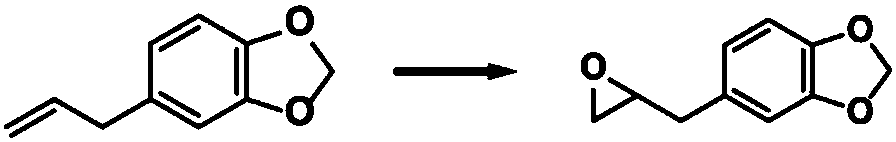

[0021] (1) Safrole epoxidation modification:

[0022] Dissolve 12 parts of m-chloroperoxybenzoic acid in 100 parts of dichloromethane, add 8 parts of safrole, and stir at 20°C for 24 hours; thereafter, the product is washed 3 times with 2% aqueous sodium hydroxide solution, and then used to remove Ionized water was washed 3 times; finally, the oil layer was dried with anhydrous magnesium sulfate, filtered and distilled under reduced pressure to obtain epoxidized safrole;

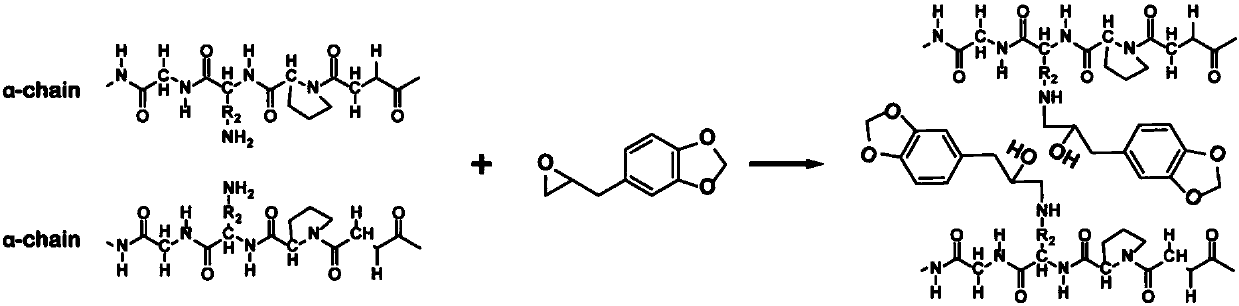

[0023] (2) Epoxidized safrole grafted modified collagen:

[0024] Dissolve 10 parts of collagen in 0.2mol / L acetic acid aqueous solution, then coat the above mixture to form a film, and dry it at 20°C to constant weight; then soak the above collagen film in pH value 7, epoxidized safrole concentration 3% aqueous solution; after 12 hours, the collagen film was taken out and washed three times with deionized water to obtain epoxidized safrole grafted modified collagen.

[0025] The results of infrared spectr...

Embodiment 2

[0027] (1) Safrole epoxidation modification:

[0028] Dissolve 15 parts of iodosobenzene in 150 parts of chloroform, add 10 parts of safrole, and stir for 20 hours at 25°C; after this, the product is washed 4 times with 5% potassium hydroxide aqueous solution, and then washed with deionized water for 5 time; at last, the oil layer is dried with anhydrous magnesium sulfate, and after filtration, vacuum distillation obtains epoxidized safrole;

[0029] (2) Epoxidized safrole grafted modified collagen:

[0030] Dissolve 15 parts of collagen in 0.4 mol / L acetic acid aqueous solution, then coat the above mixture to form a film, and dry it at 22°C to constant weight; then soak the above collagen film in pH 8, epoxidized safrole concentration 7% aqueous solution; after 24 hours, the collagen film was taken out and washed 4 times with deionized water to obtain epoxidized safrole grafted modified collagen.

[0031] The results of infrared spectroscopy and circular dichroism experimen...

Embodiment 3

[0033] (1) Safrole epoxidation modification:

[0034] Dissolve 20 parts of tert-butanol peroxide in 200 parts of carbon tetrachloride, add 12 parts of safrole, and stir at 30° C. for 12 hours; after this, the product is washed 5 times with 7% aqueous sodium bicarbonate solution, and then used to remove Washing with deionized water for 5 times; finally, the oil layer was dried with anhydrous magnesium sulfate, filtered and distilled under reduced pressure to obtain epoxidized safrole;

[0035] (2) Epoxidized safrole grafted modified collagen:

[0036] Dissolve 20 parts of collagen in 0.5 mol / L acetic acid aqueous solution, then coat the above mixture to form a film, and dry it at 25°C to constant weight; then soak the above collagen film in pH 9, epoxidized safrole concentration 10% aqueous solution; after 48 hours, the collagen film was taken out and washed 5 times with deionized water to obtain epoxidized safrole grafted modified collagen.

[0037] The results of infrared s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com