Erosion-resistant water-permeable concrete cementing material

A permeable concrete and binder technology, applied in the field of urban pavement structure, can solve problems such as unseen components and concept innovation, and achieve the effects of improving water permeability, reducing sensitivity, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

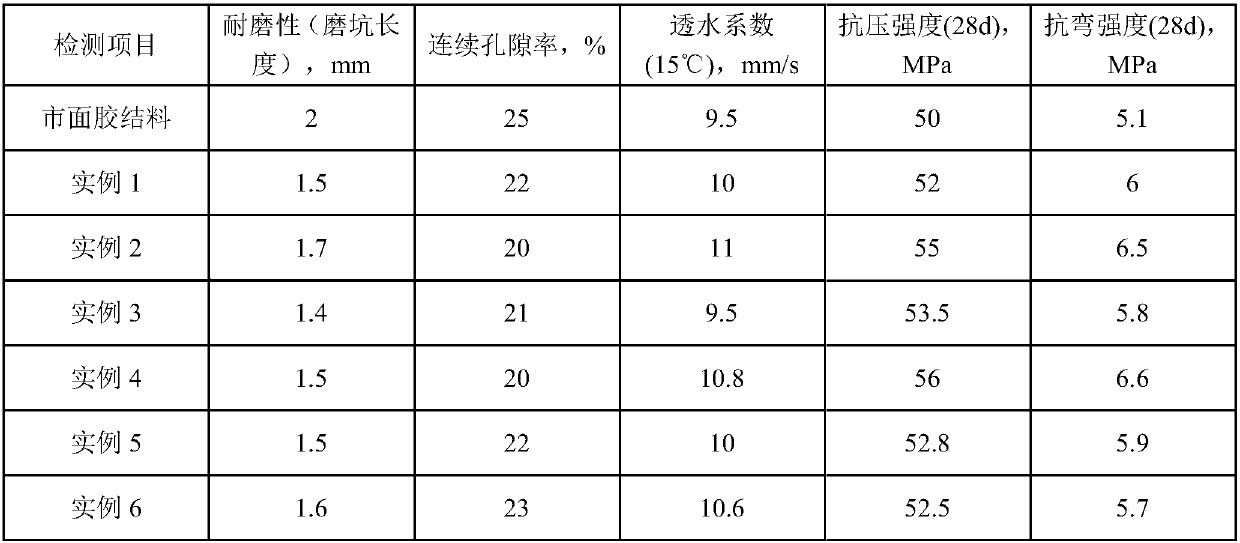

Examples

Embodiment 2

[0050] An erosion-resistant permeable concrete binder, its raw material formula includes the following components by weight percentage:

[0051] P.O52.5: 34%;

[0052] The composition is CaO: 60wt%, Al 2 o 3 : 25wt%, Fe 2 o 3 : 15wt% high-iron calcium aluminate cement: 18%;

[0053] Ultrafine mineral powder with a specific surface area of 852: 20%;

[0055] Wenlun glue: 0.6%;

[0056] 2D Aperture Zeolite powder: 1.3%;

[0057] Polycarboxylate superplasticizer powder: 0.7%;

[0058] Sulfamate superplasticizer powder: 0.5%;

[0059] Nonylphenol polyoxyethylene ether phosphate monoester: 0.2%;

[0060] Propylene glycol polyoxypropylene polyoxyethylene block polyether: 0.2%;

[0061] Magnesium stearate: 2.0%;

[0063] Butter-wrapped silane-based hydrophobic powder SHP 50 (the mass ratio of tallow to silane-based hydrophobic powder SHP 50 is 1.2:1, and the mixed powder formed by the two is sieved with a f...

Embodiment 3

[0065] An erosion-resistant permeable concrete binder, its raw material formula includes the following components by weight percentage:

[0066] P.O42.5: 39%;

[0067] The composition is CaO: 62wt%, Al 2 o 3 : 23wt%, Fe 2 o 3 : 15wt% high-iron calcium aluminate cement: 11%;

[0068] Specific surface area 871m 2 / kg ultrafine mineral powder: 24%;

[0070] Natural gum: 1.7%;

[0071] 2D Aperture Zeolite powder: 2.3%;

[0072] Polycarboxylate superplasticizer powder: 1.0%;

[0073] Sulfamate superplasticizer powder: 0.3%;

[0074] Nonylphenol polyoxyethylene ether phosphate monoester: 0.1%;

[0075] Cadmium stearate: 5.0%;

[0076] Silane-based hydrophobic powder SHP 50 wrapped in sheep oil (the mass ratio of sheep oil and silicon-based hydrophobic powder SHP 50 is 2:1, and the mixed powder formed by the two is sieved with a fineness of 200 mesh and 95%): 0.5%.

Embodiment 4

[0078] An erosion-resistant permeable concrete binder, its raw material formula includes the following components by weight percentage:

[0079] P.O52.5R: 40%;

[0080] The composition is CaO: 64wt%, Al 2 o 3 : 23wt%, Fe 2 o 3 : 13wt% high-iron calcium aluminate cement: 19%;

[0081] Specific surface area 817m 2 / kg ultrafine mineral powder: 19%;

[0082] Magnesium sulfate: 12%;

[0083] Wenlun rubber: 1.9%;

[0084] 2D Aperture Zeolite powder: 3.1%;

[0085] Polycarboxylate superplasticizer powder: 1.0%;

[0086] Sulfamate superplasticizer powder: 0.5%

[0087] Sodium tetradecyl polyoxyethylene ether succinate monoester sulfonate: 0.3%;

[0088] Aluminum stearate: 2.5%;

[0089] Silane-based hydrophobic powder SHP 50 wrapped in sheep oil (the mass ratio of sheep oil and silane-based hydrophobic powder SHP 50 is 1.5:1, and the mixed powder formed by the two is sieved with a fineness of 200 mesh and 95%): 0.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com