Flywheel cover drilling clamp

A technology for drilling jigs and flywheels, applied in clamping, manufacturing tools, supports, etc., can solve the problems of complex clamping process, uneven drilling, and high equipment cost of flywheel cover jigs, and achieve simple structure, low manufacturing cost, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

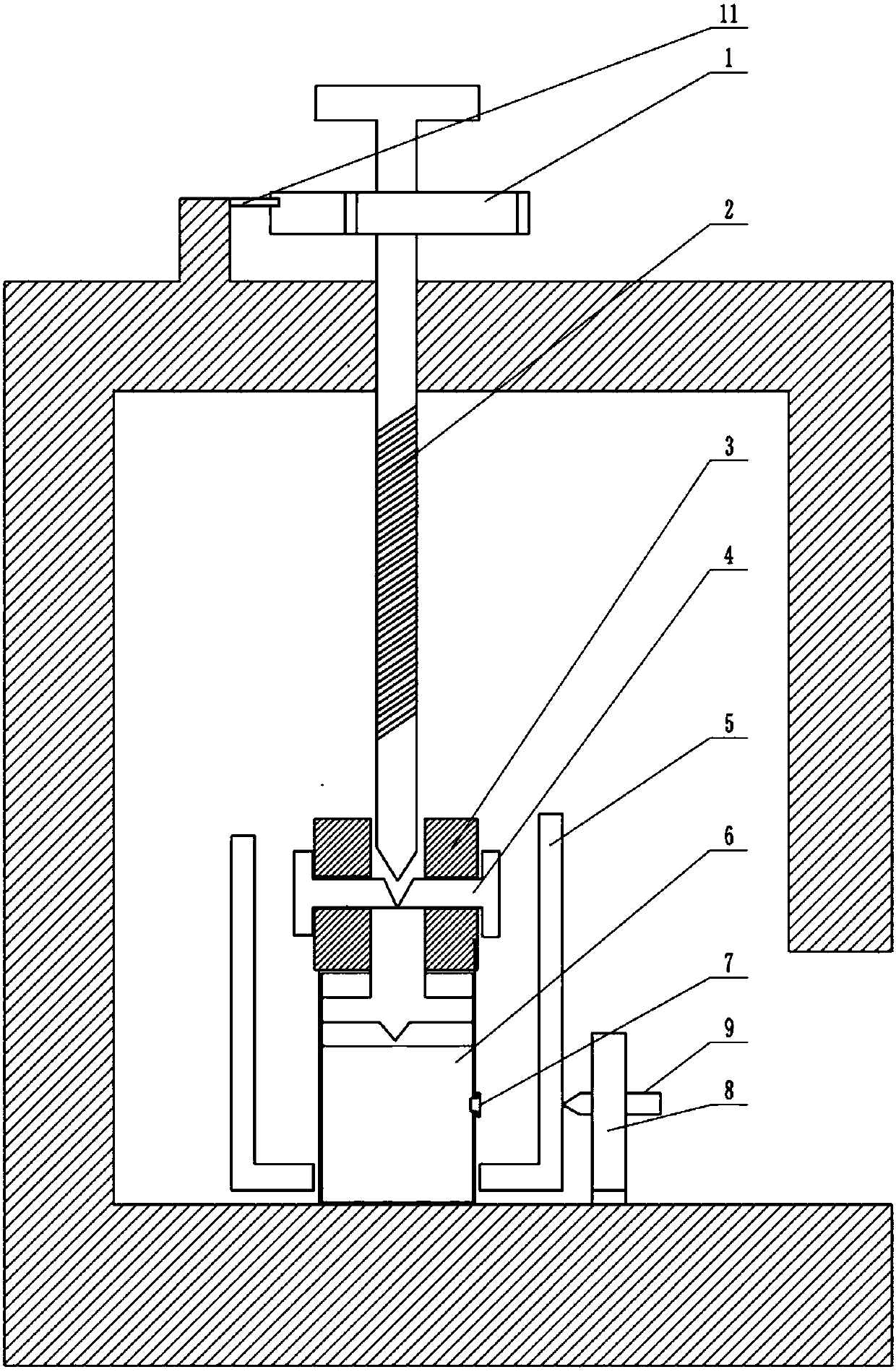

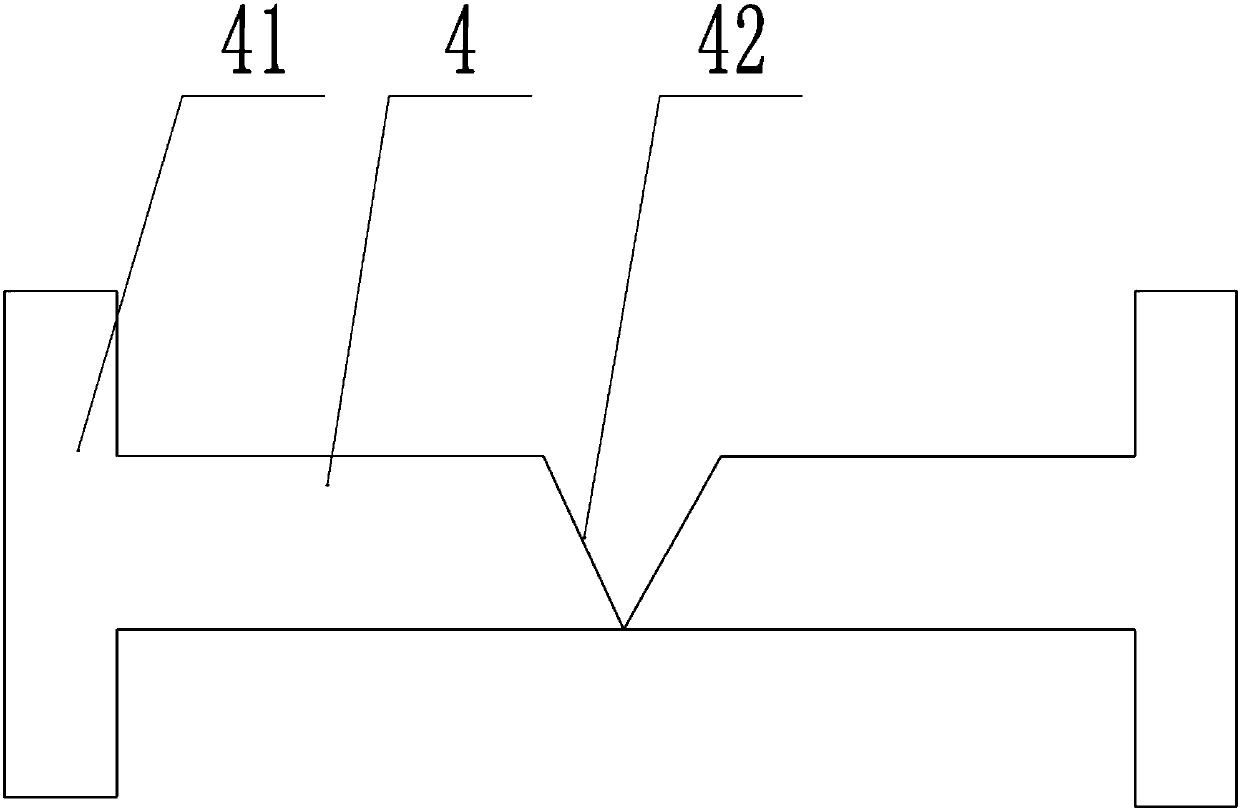

[0019] like figure 1 and figure 2 As shown, a flywheel cover drilling jig includes a cuboid frame, the top surface of the frame is rotatably connected with a vertical threaded rod 2, the upper end of the threaded rod 2 is a free end, the lower end of the threaded rod 2 is provided with a spike, and the threaded rod 2 The free end is provided with a rotating handle, and the threaded rod 2 is coaxially connected with a ratchet 1, and the ratchet 1 is located on the top surface of the frame, and the top surface of the frame is rotatably connected with a pawl 11, and the ratchet 1 and the pawl 11 are engaged; A clamping ring 3 is threadedly connected, and the lower end of the clamping ring 3 is symmetrically provided with two through holes along the central axis of the clamping ring 3, and a tension rod 4 is slidingly connected in the through hole, and one end of the tension rod 4 is provided with a wedge-shaped surface 42 , the other end of the tension rod is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com