Special waste gas filtering tool for preparing green starch packaging membrane

A waste gas filtration and packaging film technology, which is applied in transportation and packaging, dispersed particle filtration, and dispersed particle separation, etc., can solve air pollution and other problems, and achieve the effects of improving the use effect, improving the filtration efficiency, and long service life

Pending Publication Date: 2018-04-13

DANYANG HUACHENG PACKAGING CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of producing starch packaging film, since plant starch needs to be crushed and mixed with other reactants, the exhaust gas generated during the production process will be mixed with dust particles. If it is directly discharged into the atmosphere, it will cause air pollution. Therefore, Research and development on the recycling of waste gas produced by the preparation of green starch packaging films has attracted more and more people's attention

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] In order to make the technical solution of the present invention clearer, the present invention is further described below, and any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

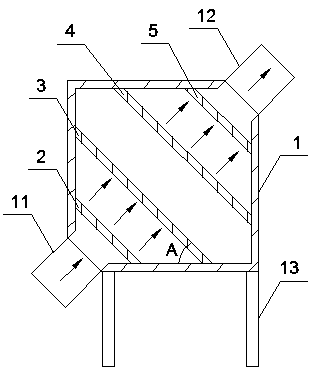

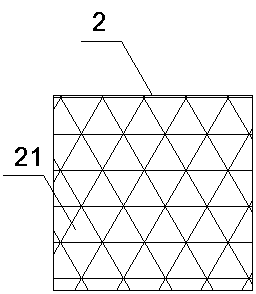

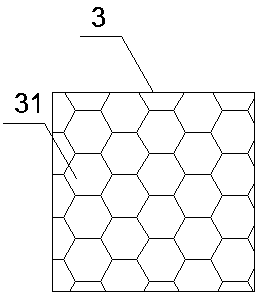

The invention discloses a special waste gas filtering tool for preparing a green starch packaging membrane. A filtering tool shell is of an unfilled corner cube structure; an air inlet is formed in the bottom on one side of the filtering tool shell; an air outlet is formed in the top of the other side of the filtering tool shell; both the air inlet and the air outlet are formed in an inclined manner; support feet are arranged at the bottom of the filtering tool shell; four filtering nets are arranged inside the filtering tool shell, namely a first filtering net, a second filtering net, a thirdfiltering net and a fourth filtering net in sequence from the air inlet to the air outlet; the four filtering nets are arranged in the filtering tool in the inclined manner; the four filtering nets are parallel to one another; and an included angle A of 45 degrees is formed between one of the four filtering nets and the bottom surface inside the filtering tool shell. Due to adoption of multiple different filtering layers, the tool is capable of effectively filtering granules in waste gases, and the granules are prevented from entering the atmosphere to cause dust pollution.

Description

technical field [0001] The invention relates to a waste gas treatment tool, in particular to a special waste gas filtering tool for the preparation of green starch packaging film. Background technique [0002] Synthetic films are generally plastic polymers. The production process and product waste will cause huge damage to the natural ecological environment, and the raw materials used to produce such films are petroleum products, which are non-renewable resources. Compared with artificially synthesized polymer films, natural plant starch as a packaging film material has the advantages of non-toxic, harmless, green and environmentally friendly, and biodegradable. However, in the process of producing starch packaging film, since plant starch needs to be crushed and mixed with other reactants, the exhaust gas generated during the production process will be mixed with dust particles. If it is directly discharged into the atmosphere, it will cause air pollution. Therefore, The r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D46/12

CPCB01D46/12B01D46/62

Inventor 谢韬谢华良

Owner DANYANG HUACHENG PACKAGING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com