Protective reinforced rib template for construction

A protective and architectural technology, which is applied in the direction of construction, building components, building materials, etc., can solve the problems of incomplete hydration of concrete cement, complex process of formwork installation and formwork removal, and impact on the durability of reinforced concrete structures. , to achieve the effects of clean construction, convenient transportation, construction and installation, and economical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

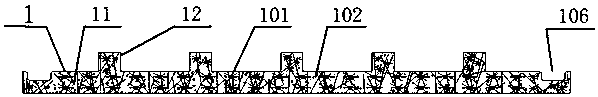

[0033] like figure 1 As shown, a protective rib formwork for construction mainly includes a rigid fiber mortar rib formwork 1, and the rigid fiber mortar rib formwork 1 includes a flat rib plate 11 and a rib 12, and the rib 12 is vertically fixed to the flat rib On the inner surface of the board 11; the flat-shaped ribs 11 and ribs 12 are all made of steel wire ropes 101 and fiber cement mortar 102 integrated through the pouring molding process, and the steel wire ropes 101 are longitudinally spaced on the fiber cement mortar 102 Middle; the width of the flat rib 11 is 600mm, the length is 10000mm, the thickness is 15mm, the thickness of the rib 12 is 15mm, the thickness of the flat rib 11 plus the thickness of the rib 12 is 30mm in total, and the adjacent rib 12 is 300mm The distance between the ribs is distributed longitudinally and parallel on the inner surface of the flat-shaped rib 11; the edge of the inner surface of the flat-shaped rib 11 is provided with a U-shaped ten...

Embodiment 2

[0035] like figure 2As shown, a protective rib formwork for construction mainly includes a rigid fiber mortar rib formwork 1 and a connecting member 2, and the rigid fiber mortar rib formwork 1 includes a flat rib plate 11 and ribs 12, and the ribs 12 are vertically fixed on the inner surface of the flat ribbed plate 11; the flat ribbed plate 11 and the ribs 12 are all made of fiber cement mortar 102 and steel fiber mesh 103 through molding process, and the steel fiber mesh 103 and fiber cement mortar 102 is firmly combined and coated on the surface of the rigid fiber mortar rib formwork 1; the width of the flat rib 11 is 500 mm, the length is 1000 mm, and the thickness is 10 mm; the thickness of the rib 12 is 15 mm; the thickness of the flat rib 11 plus The total thickness of the ribs 12 is 25 mm, and the adjacent ribs 12 are longitudinally and parallel distributed on the inner surface of the flat rib 11 at a distance of 40 mm; , used for the tongue-and-groove sealing conne...

Embodiment 3

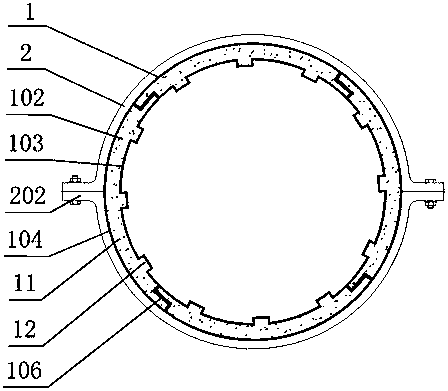

[0037] like image 3 As shown, a protective rib formwork frame for a column mainly includes 4 rigid mortar rib formwork 1 and connecting members 2, and the rigid mortar rib formwork 1 mainly includes arc-shaped rib plates 11 and ribs 12, ribs 12 is vertically fixed on the inner surface of the arc-shaped rib 11; the arc-shaped rib 11 and the ribs 12 are all made of cement mortar 102, nylon fiber net 103, and cotton and linen fiber cloth 104. Made, nylon fiber mesh 103 and cement mortar 102 are firmly combined on the inner side of the rigid mortar rib formwork 1, cotton fiber cloth 104 and cement mortar 102 are firmly combined on the outer side of the rigid mortar rib formwork 1; 11 width is 500mm, arc length is 1500, degree of arc is 90°, thickness is 10mm, thickness of rib 12 is 15mm, the thickness of arc-shaped rib plate 11 plus the thickness of rib 12 add up to 25mm, adjacent rib 12 The arc length of 200mm is distributed longitudinally and parallelly on the inner surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com