Zr-Nb-based alloy with good additive manufacturing forming performance and application of Zr-Nb-based alloy

A technology of additive manufacturing and formability, which is applied in the field of Zr-Nb based alloys, can solve the problems that the mechanical properties of additive manufacturing components cannot be fully utilized, and achieve the effects of good comprehensive mechanical properties, low magnetic susceptibility, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples will further illustrate the invention.

[0014] Based on Zr-Nb alloy, the atomic integer substitution of alloy elements was carried out according to the double-cluster alloy design model.

[0015] The specific embodiments of the present invention are described below in conjunction with specific experimental steps.

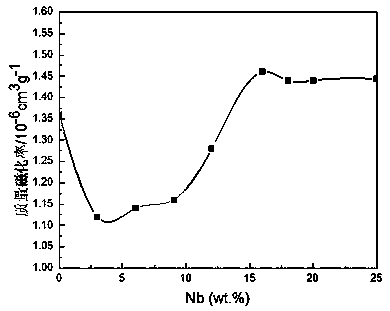

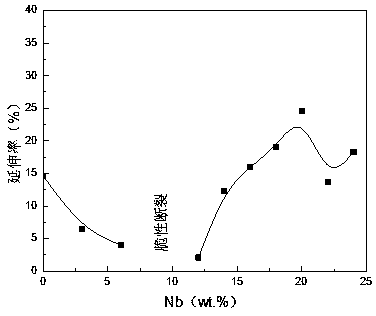

[0016] 1. Preparation of alloys: According to the design model of double-cluster alloys [Zr-Zr 14 +Zr-Zr 8 Nb 6 ]NbZr=Nb 7 Zr 25 , the binary alloy composition is Nb 21.8 Zr 78.2 (at.%), the element is converted from atomic percentage to mass percentage of 22.1Nb-77.9Zr (wt.%) for composition ratio; the prepared alloy raw material is smelted multiple times under the protection of Ar gas atmosphere in a vacuum arc furnace , the alloy composition is uniform, and the master alloy ingot is obtained. The ingredients are in figure 1 near the eutectic point.

[0017] 2. Observation of as-cast microstructure: metallographic preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com