Cellulase immobilization and cellulose hydrolysis methods

A technology of cellulase and cellulose, applied to biochemical equipment and methods, fixed on/in organic carriers, enzymes, etc., can solve problems such as increased steric hindrance, unfavorable cellulase hydrolysis, etc., to achieve The effect of reducing the Michaelis constant, increasing the degradation rate of TS, and increasing the fixation rate of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Method for cellulase immobilization using sodium alginate-polyethylene glycol-chitosan

[0027] 1) Accurately weigh the cellulase powder and dissolve it in pure water to make the concentration 5mg / ml, set aside.

[0028] 2) Accurately weigh 1.5g chitosan in a 100ml beaker, add 48.5g mass fraction of 2% acetic acid to make the mass fraction of chitosan 3%, after mixing uniformly at room temperature, form a chitosan solution for use .

[0029] 3) Accurately weigh glutaraldehyde to be configured into a 1% glutaraldehyde solution by mass fraction, and set aside;

[0030] 4) Immobilization of cellulase: Accurately weigh 2.625g of polyethylene glycol in a 100ml beaker, add 48.25g of 0.05mol / L citric acid-sodium citrate buffer solution with pH=4.8, stir with a glass rod at room temperature After dissolving, 1.75 g of sodium alginate was added so that the mass fraction of sodium alginate was 3.5%, and the mass ratio of sodium alginate to polyethylene glycol was 1:1.5. After ...

Embodiment 2

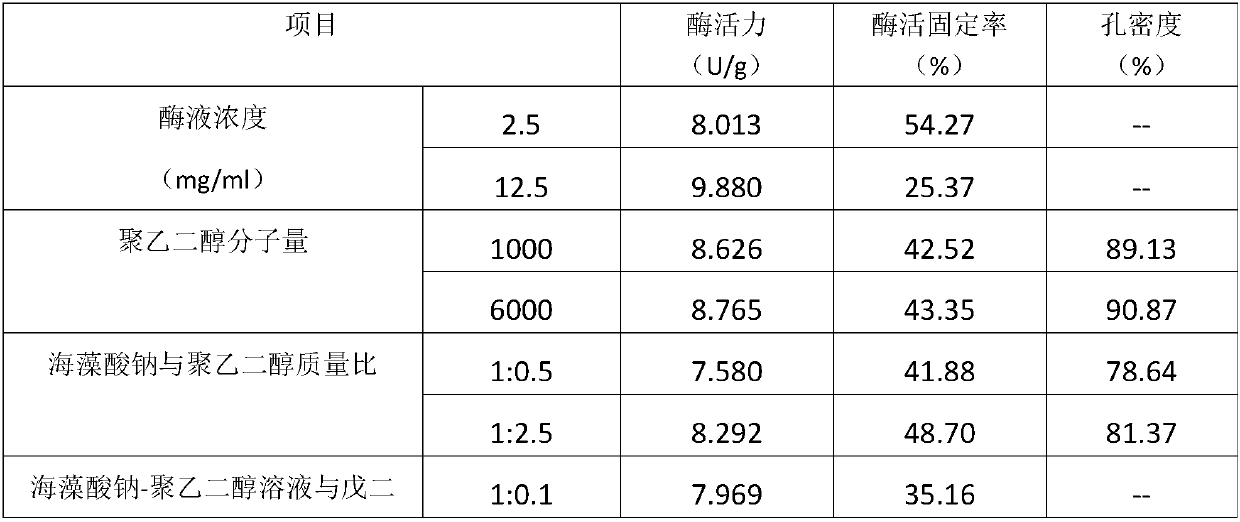

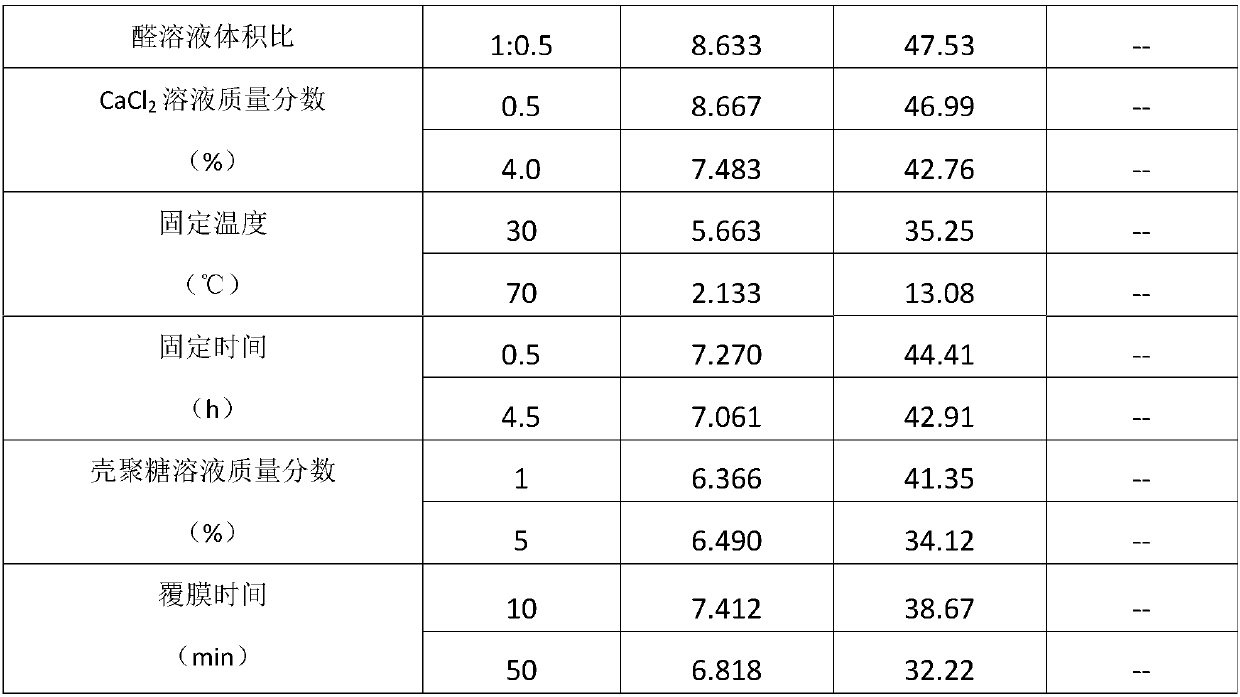

[0037] The preparation of sodium alginate-polyethylene glycol-chitosan immobilized cellulase, operation is the same as embodiment 1, fixation condition gets respectively the lowest value and the highest value described in "summary of the invention" of each factor, to immobilization The enzyme conditions were optimized and analyzed, and the results are shown in Table 2.

[0038] Table 2 Condition optimization analysis of immobilized cellulase

[0039]

[0040]

Embodiment 3

[0042] Sodium alginate-polyethylene glycol-chitosan immobilized cellulase for hydrolysis of microcrystalline cellulose

[0043] 1) Sodium alginate-polyethylene glycol-chitosan immobilized cellulase enzymatically hydrolyzes microcrystalline cellulose: a 50 ml shake flask is used. 0.5 g of TS microcrystalline cellulose was added, the dosage of immobilized enzyme was 1.745 g, and a citric acid-sodium citrate buffer solution with pH=4.93 was added to make the substrate mass fraction 6.89%. Parafilm seals to prevent moisture from evaporating. Enzymatically hydrolyze at 60°C and 150r / min for 48h, suction filter after the reaction, measure the reducing sugar content in the filtrate to obtain the enzymatic hydrolysis yield; after drying the solid residue, measure the mass change before and after the reaction.

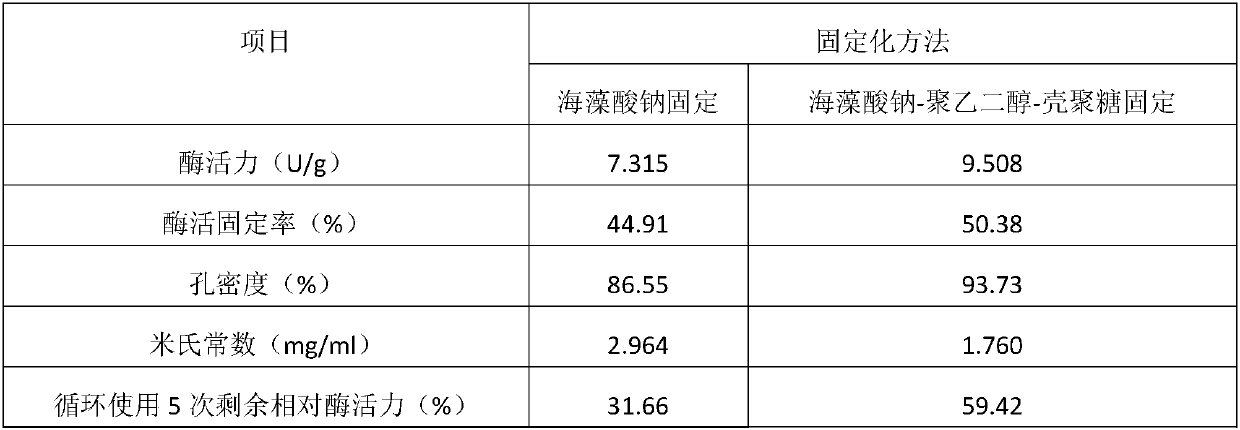

[0044] 2) In order to illustrate the advantages of the immobilization method of the present invention, use sodium alginate immobilized cellulase to enzymatically hydrolyze mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com