Oxygen and nitrogen co-doped graded porous carbon nanosheet electrode material as well as preparation method and application thereof

A technology of hierarchical porous and electrode materials, which is applied in nanotechnology, nanotechnology, battery electrodes, etc. for materials and surface science, can solve problems such as poor rate performance, and achieve simple preparation methods, low cost, and rich doping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

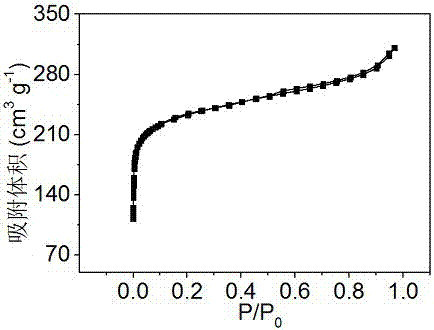

Embodiment 1

[0032] Add 10 g bovine bone particles into a porcelain boat and place in a tube furnace, under the protection of an inert atmosphere, at 2.5 °C min -1 The temperature was raised to 400 °C and kept at this temperature for 3 h. After the tube furnace was lowered to room temperature, the heat-treated product was taken out and mixed with KOH at a ratio of 1:1.4. The mixture was added to a corundum porcelain boat and placed in a tube furnace under the protection of an inert atmosphere at 2.5 °C min -1 The temperature was raised to 550 °C and kept at this temperature for 1 h. After the tube furnace was lowered to room temperature, the heat-treated product was taken out and soaked in 1 M dilute hydrochloric acid for 12 h, and then washed with deionized water until neutrally dried to obtain a nitrogen-oxygen co-doped hierarchical porous carbon nanosheet electrode material ( figure 1 and 2 ). Its specific surface area is 890 m 2 g -1 , the pore volume is 0.48 cm3 g -1 , The ni...

Embodiment 2

[0037] The operating conditions are the same as in Example 1, except that the animal bones used are fish scales. The obtained nitrogen-oxygen co-doped hierarchical porous carbon nanosheet electrode material has a specific surface area of 810 m 2 g -1 , the pore volume is 0.42 cm 3 g -1 , The nitrogen content is 6.9 at.%, the oxygen content is 18.1 at.%, and the carbon layer spacing is 0.42 nm.

[0038] Adopt the method identical with embodiment 1 to carry out electrochemical test, the result shows, current density is 0.7 A g -1 After 1000 cycles, the specific capacity can still be maintained at 190 mAh g -1 , with a current density of 7 A g -1 After 10,000 cycles, the specific capacity can still be maintained at 125 mAh g -1 The reversible specific capacities under step current density are 195, 181, 150, 128, 115, 105 mAh g -1 .

Embodiment 3

[0040] Operating condition is the same as embodiment 1, and difference is 2.5 ° C min of heating rate -1 . The obtained nitrogen-oxygen co-doped hierarchical porous carbon nanosheet electrode material has a specific surface area of 905 m 2 g -1 , the pore volume is 0.50 cm 3 g -1 , The nitrogen content is 6.8 at.%, the oxygen content is 18.5 at.%, and the carbon layer spacing is 0.40 nm.

[0041] Adopt the method identical with embodiment 1 to carry out electrochemical test, the result shows, current density is 0.7 A g -1 After 1000 cycles, the specific capacity can still be maintained at 188 mAh g -1 , with a current density of 7 A g -1 Under the same conditions, the specific capacity can still be maintained at 123 mAh g after 10,000 cycles -1 The reversible specific capacities under step current density are 195, 182, 154, 125, 113, 102 mAh g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com