Method for Improving Plasticity of Cast Al-Li Alloy

A lithium alloy and casting aluminum technology, which is applied in the field of non-ferrous metals, can solve the problems of damaging the plasticity of the alloy, weakening and refining the aluminum alloy grain, and the plasticity improvement of the cast aluminum-lithium alloy is not obvious, so as to achieve favorable alloy plasticity and improve alloy plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Through the chemical analysis of adopting aforementioned method to prepare alloy, its composition is as shown in the following table (wt%):

[0038] Li Cu Zr sc Al 3.11 1.89 0.19 0.09 / 0.25 margin

[0039] The mechanical properties of the alloy after "pre-aging" and solution and aging treatment are as follows:

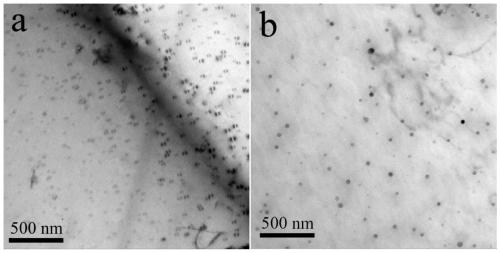

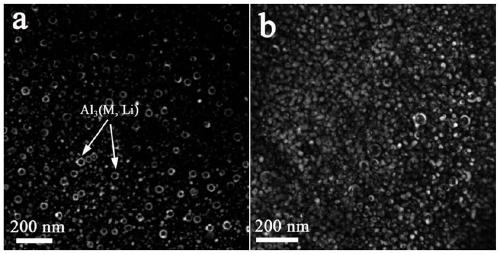

[0040] The alloy containing 0.09Sc is: tensile strength 418MPa, yield strength 327MPa, elongation 4.2%; the alloy containing 0.25Sc is: tensile strength 442MPa, yield strength 336MPa, elongation 6.1%. The transmission bright-field phase of the aged cast aluminum-lithium alloy prepared in this example is as follows figure 2 as shown in a.

Embodiment 2

[0042] Adopt aforementioned method to prepare alloy through chemical analysis, its composition is (wt%):

[0043] Li Cu Zr Yb Al 2.89 2.15 0.14 0.12 / 0.23 margin

[0044] The mechanical properties of the alloy after "pre-aging" and solution and aging treatment are as follows:

[0045] Containing 0.12Yb: tensile strength 408MPa, yield strength 321MPa, elongation 3.7%;

[0046] Containing 0.23Yb: tensile strength 423MPa, yield strength 337MPa, elongation 4.8%.

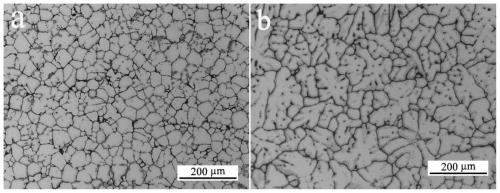

[0047] The as-cast metallographic structure of the cast aluminum-lithium alloy prepared in this embodiment is as follows: figure 1 as shown in a.

Embodiment 3

[0049] Adopt aforementioned method to prepare alloy through chemical analysis, its composition is (wt%):

[0050] Li Cu sc Yb Al 2.95 2.04 0.2 0.15 margin

[0051] The mechanical properties of the alloy after "pre-aging" and solid solution and aging treatment are:

[0052] The tensile strength is 425MPa, the yield strength is 334MPa, and the elongation is 4.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com