Aqueous epoxy modified silicon resin coating and preparation method thereof

A water-based epoxy and resin coating technology, applied in coating and other directions, to achieve the effect of reducing energy consumption, easy control of reaction, and large utilization rate of equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

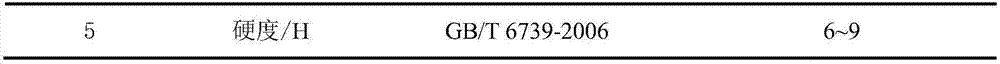

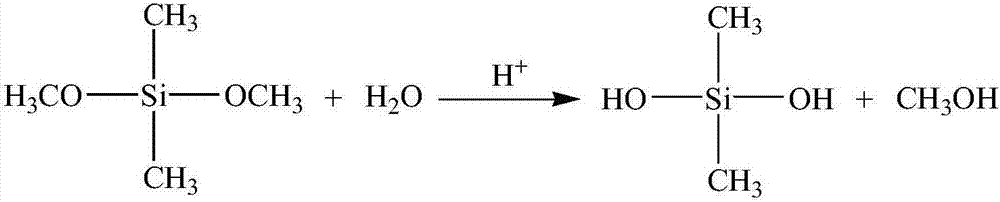

[0021] Add 100g of dimethyldimethoxysilane, 400g of methyltrimethoxysilane and 100g of silane coupling agent KH-560 into a container with a stirring device in turn, start stirring, and add 100g in turn at a speed of 300r / min Distilled water and 10g acetic acid, after the reaction system is exothermic, add 150g methanol and 50g diacetone alcohol, stir and mix evenly and let it stand for 12h, then weigh 100g of the prepared base resin, and weigh 5 parts of butyl titanate and mix Evenly, the epoxy-modified silicone resin coating is prepared, and the coating is smeared on the surface of the copper sheet with a thickness of 50 μm, and the curing is completed by heating at 150 ° C for 5 to 8 minutes, and the hardness of the obtained coating is 9H.

Embodiment 2

[0023] Add 300g of methyltrimethoxysilane, 200g of dimethyldimethoxysilane and 150g of silane coupling agent KH-560 into a container with a stirring device in turn, start stirring, and add 150g of Distilled water and 12g acetic acid, after the reaction system is exothermic, add 180g methanol and 60g diacetone alcohol, stir and mix evenly and let it stand for 12h, then weigh 100g of the prepared base resin, and weigh 6 parts of butyl titanate and mix Evenly, the epoxy-modified silicone resin coating is prepared, and the coating is smeared on the surface of PVC with a thickness of 150 μm, and it can be cured after being placed at room temperature for 6-8 hours, and the hardness of the obtained coating is ≥6H.

[0024] The coatings obtained in Examples 1 and 2 were tested for performance, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com