A kind of modified polypropylene material and its preparation method and application

A polypropylene material and modification technology, applied in the field of polypropylene materials, can solve the problems of material performance decline, affecting product functions, etc., and achieve the effects of low cost, improved production efficiency, and simple processing technology

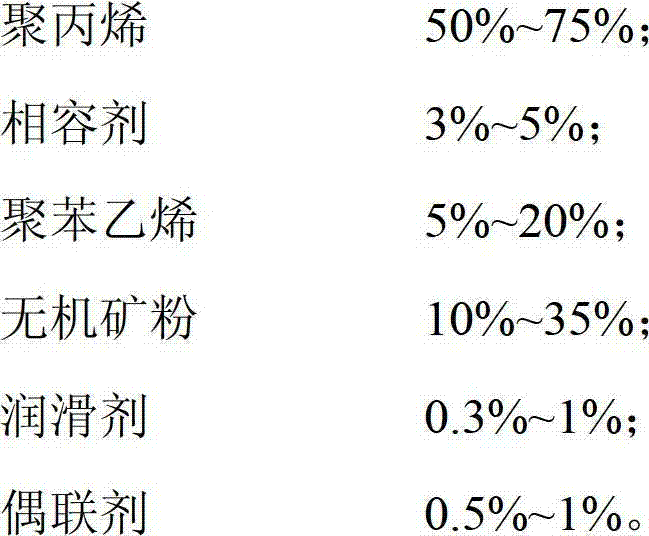

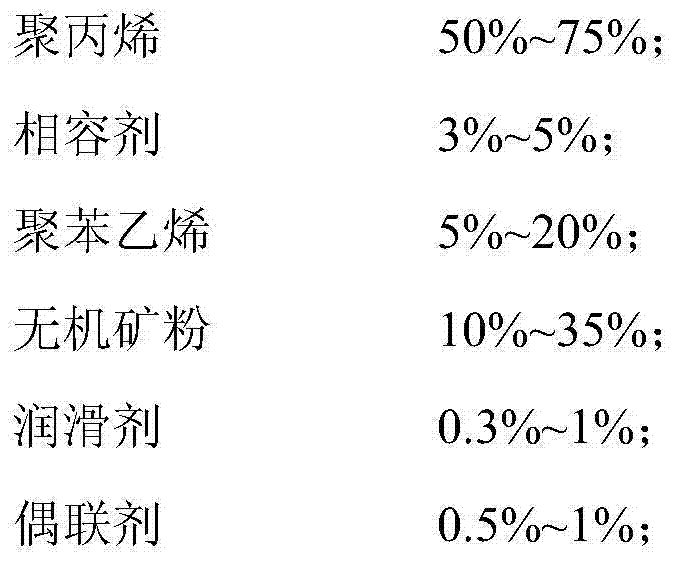

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

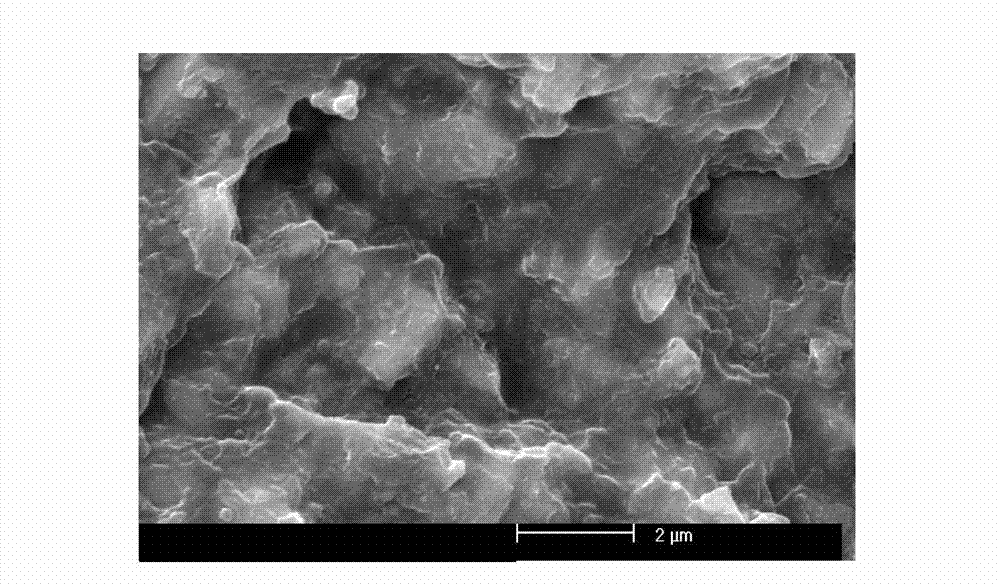

Image

Examples

Embodiment 1

[0029] According to the following formula: homopolypropylene 35%; copolymerized polypropylene 15%; polypropylene grafted maleic anhydride 5%; polystyrene 10%; talc 33%; 3-aminopropyltriethoxysilane 1% ; Ethylene bis stearamide 1% blending extrusion granulation into PP modified materials and molding products and post-processing.

[0030] The specific implementation steps are:

[0031] Step 1: Weigh the talcum powder according to the mass ratio, add it into the high-speed mixer and stir for 20-30 minutes (rotation speed is 1000r / min), dry the talcum powder and the temperature reaches 120°C.

[0032] Step 2: Weigh the 3-aminopropyltriethoxysilane coupling agent according to the mass ratio, and evenly spray the 3-aminopropyltriethoxysilane coupling agent on the stirring talcum powder.

[0033] Step 3: After spraying the coupling agent, continue to stir at high speed for 20-30 minutes (rotation speed: 2000r / min), add ethylene bis-stearamide weighed according to the mass ratio, and...

Embodiment 2

[0040] According to the following formula: homopolypropylene 15%; copolymerized polypropylene 35%; polypropylene grafted maleic anhydride 5%; polystyrene 10%; calcium carbonate powder 33%; Acyloxy) titanate 1%; Ethylene bis stearamide 1% blending, extruding, granulating into PP modified material and forming products and post-processing.

[0041] The specific implementation steps are:

[0042] Step 1: Weigh the calcium carbonate powder according to the mass ratio, add it into the high-speed mixer and stir for 20-30 minutes (the speed is 1000r / min), so that the calcium carbonate powder is dried and the temperature reaches 120°C.

[0043] Step 2: Weigh tetraisopropyl bis (dioctyl phosphite acyloxy) titanate coupling agent according to the mass ratio, and couple tetraisopropyl bis (dioctyl phosphite acyl) titanate The joint agent is evenly sprayed onto the calcium carbonate powder being stirred.

[0044] Step 3: After spraying the coupling agent, continue to stir at high speed f...

Embodiment 3

[0051] According to the following formula: homopolypropylene 15%; copolymerized polypropylene 35%; polypropylene grafted maleic anhydride 5%; polystyrene 20%; alumina powder 10%; calcium carbonate powder 13%; (Dioctyl phosphite acyloxy) titanate 1%; Ethylene bis stearamide 1% blending extrusion granulation into PP modified material and molding products and post-treatment.

[0052] The specific implementation steps are:

[0053] Step 1: Weigh the alumina powder and calcium carbonate powder according to the mass ratio, add them into a high-speed mixer and stir for 20-30 minutes (rotation speed: 1000r / min), dry the alumina powder and calcium carbonate powder and the temperature reaches 120°C.

[0054] Step 2: Weigh tetraisopropyl bis (dioctyl phosphite acyloxy) titanate coupling agent according to the mass ratio, and couple tetraisopropyl bis (dioctyl phosphite acyl) titanate The joint agent is evenly sprayed onto the calcium carbonate powder being stirred.

[0055] Step 3: Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com