Polyimide film

A polyimide film and film-forming technology, which can be applied to other household appliances, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of component loading position deviation, component and substrate can not be well connected, etc., to achieve The effect of small elongation on one side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

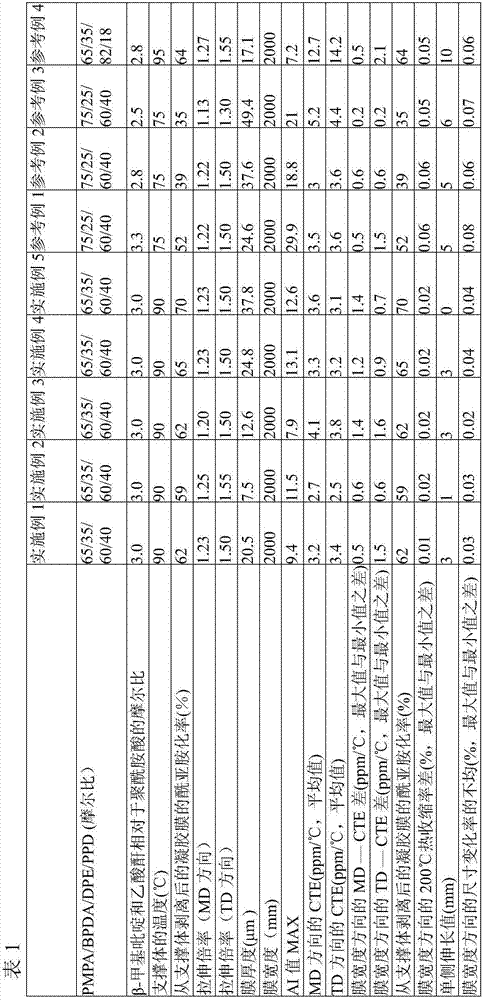

[0150] Prepare pyromellitic dianhydride (PMPA, molecular weight 218.12) / 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA, molecular weight 294.22) / 4 at a molar ratio of 65 / 35 / 60 / 40 ,4'-diaminodiphenyl ether (DPE, molecular weight 200.24) / p-phenylenediamine (PPD, molecular weight 108.14), formed 20% by weight in DMAC (N,N-dimethylacetamide) and polymerized to give 3500 poise polyamic acid solution at 25°C.

[0151] After adding β-picoline and acetic anhydride to the polyamide solution so that the molar ratio of each relative to the polyamic acid was 3.0, it was cast from a metal port onto a stainless steel support at 90°C to obtain a self-supporting polyamide solution. polyimide gel membrane.

[0152]The gel film was peeled from the support, conveyed through nip rolls, and stretched longitudinally. After longitudinal stretching, both ends of the film were held, and drying was carried out in a tenter while stretching laterally. After drying, it heat-processed using an elec...

reference example 1

[0155] Prepare pyromellitic dianhydride (PMPA, molecular weight 218.12) / 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA, molecular weight 294.22) / 4 at a molar ratio of 75 / 25 / 60 / 40 ,4'-diaminodiphenyl ether (DPE, molecular weight 200.24) / p-phenylenediamine (PPD, molecular weight 108.14), formed 20% by weight in DMAC (N,N-dimethylacetamide) and polymerized to give A polyamic acid solution of 3500 poise at 25°C was obtained.

[0156] After adding β-picoline and acetic anhydride to the polyamide solution so that the molar ratio of each relative to the polyamic acid was 3.3, it was cast on a stainless steel support at 75°C to obtain a self-supporting polyimide. Amine gel film.

[0157] The gel film was peeled from the support, conveyed through nip rolls, and stretched longitudinally. After longitudinal stretching, both ends of the film were held, and drying was carried out in a tenter while stretching laterally. After drying, it heat-processed using an electric heater, and o...

reference example 2

[0159] Prepare pyromellitic dianhydride (PMPA, molecular weight 218.12) / 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA, molecular weight 294.22) / 4 at a molar ratio of 75 / 25 / 60 / 40 ,4'-diaminodiphenyl ether (DPE, molecular weight 200.24) / p-phenylenediamine (PPD, molecular weight 108.14), formed 20% by weight in DMAC (N,N-dimethylacetamide) and polymerized to give A polyamic acid solution of 3500 poise at 25°C was obtained.

[0160] After adding β-picoline and acetic anhydride to this polyamide solution so that the molar ratio of each relative to the polyamic acid becomes 2.8, it was cast on a stainless steel support at 75°C to obtain a self-supporting polyimide. Amine gel film.

[0161] The gel film was peeled from the support, conveyed through nip rolls, and stretched longitudinally. After longitudinal stretching, both ends of the film were held, and drying was carried out in a tenter while stretching laterally. After drying, it heat-processed using an electric heater, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com