Nanoparticle/graphene oxide composite modified high polymer material and preparation thereof

A graphene composite and polymer material technology is applied in the field of nanoparticle/graphene oxide composite modified polymer materials and their preparation, which can solve the problems of easy agglomeration, harsh reaction conditions, and difficulty in large-scale production, and achieves mechanical It has the advantages of excellent tribological properties, excellent wear resistance and antifriction properties, and simple and efficient preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention further provides a method for preparing a nanoparticle / graphene oxide composite modified polymer material, comprising the following steps: (1) preparation of the nanoparticle and graphene oxide electrostatic self-assembly method: the nanoparticle is subjected to ultrasonic and mechanical Disperse into the solvent under stirring, add an appropriate amount of γ-aminopropyltriethoxysilane (KH550) dropwise to it, and then reflux in a water bath and mechanically stir to obtain an ionized positively charged amino-modified nanoparticle dispersion, add oxidation Graphene dispersion liquid, graphene oxide contains a large number of carboxyl groups, hydroxyl groups are ionized and negatively charged, ultrasonic and mechanical stirring treatment is fully contacted with positively and negatively charged amino-modified nanoparticles, and nanoparticles / graphene oxide composite particles are obtained;

[0031] (2) Wet-dry combined mixing: the nanoparticle / graphene...

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of nanoparticle / graphene oxide composite modified polymer material, comprises the steps:

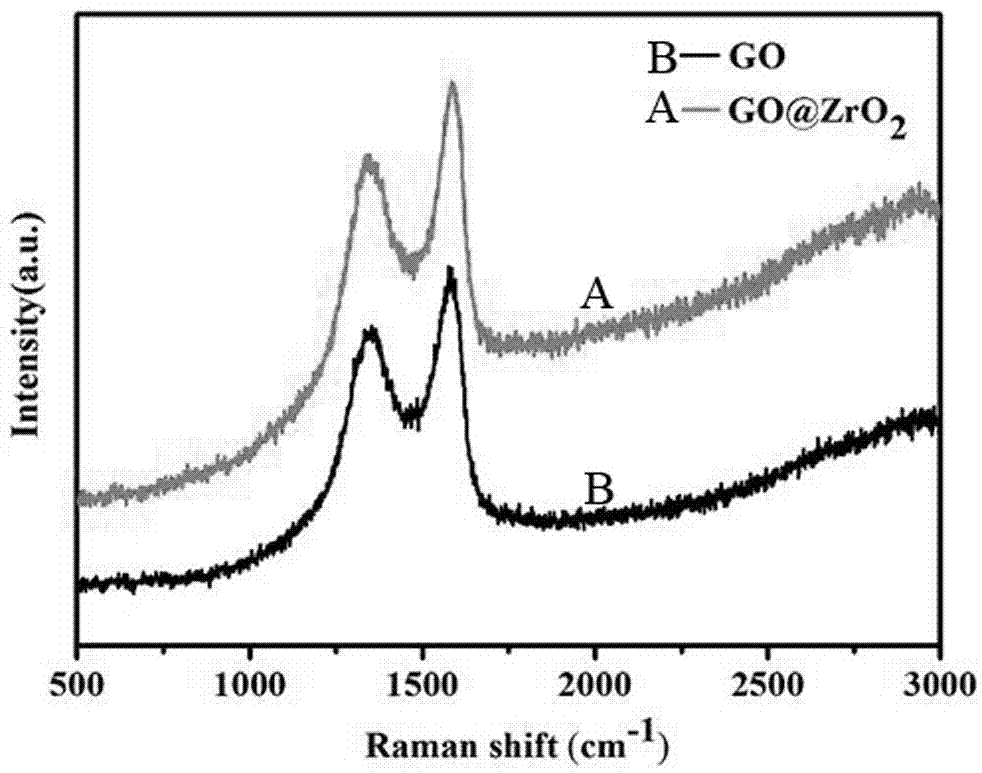

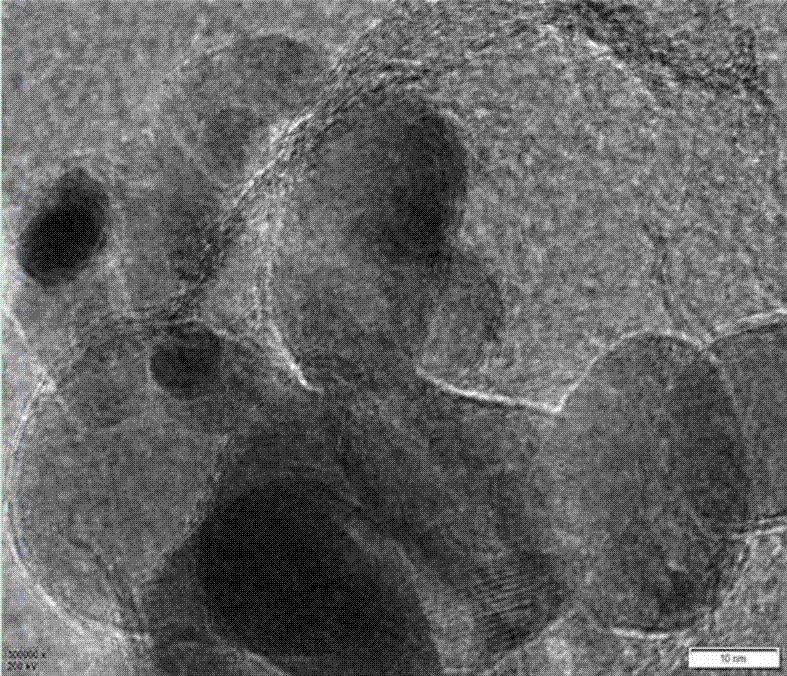

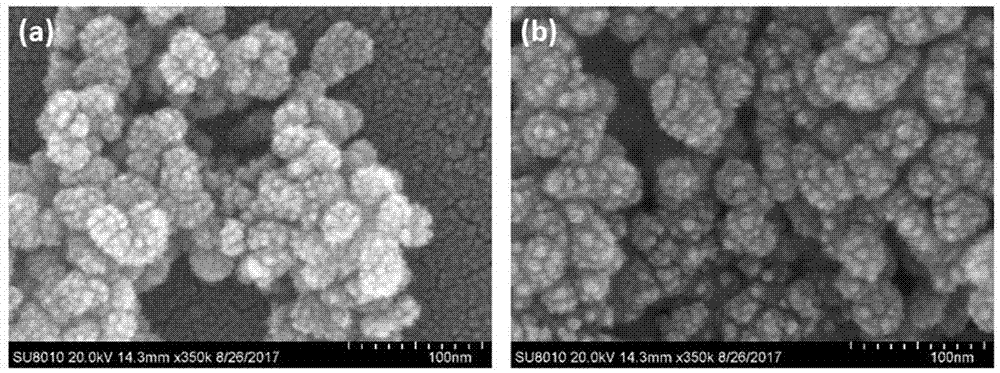

[0039] (1) ZrO 2 Electrostatic Self-Assembly Preparation of @GO Nanocomposite Particles: ZrO 2 Add nanoparticles into absolute ethanol, ultrasonically / mechanically stir (ultrasonic power is 80W, ultrasonic frequency is 40KHz, mechanical stirring speed is 1000rpm) to form a dispersion with a concentration of 10mg / mL, and 1mg / mL of γ-ammonia is added dropwise to it Propyltriethoxysilane (KH550) was treated with water bath reflux / mechanical stirring at 75°C for 4 hours to obtain ionized and positively charged amino-modified ZrO 2 Nanoparticle dispersion liquid, add GO dispersion liquid to it, make ZrO contained in the mixed solution 2 The mass ratio of GO to GO is 50:1. GO contains a large number of carboxyl groups and hydroxyl groups are ionized and negatively charged. Ultrasonic / mechanical stirring treatment makes the positive and negati...

Embodiment 2

[0047] Embodiment 2: Its preparation method of a kind of nanoparticle / graphene oxide composite modified macromolecule material, comprises the following steps:

[0048] (1) ZrO 2 Electrostatic Self-Assembly Preparation of @GO Nanocomposite Particles: ZrO 2 Add nanoparticles into absolute ethanol, ultrasonic / mechanical stirring (ultrasonic power is 80W, ultrasonic frequency is 40KHz, mechanical stirring speed is 1000rpm) to form a dispersion with a concentration of 20mg / mL, and 4mg / mL of γ-ammonia is added dropwise to it Propyltriethoxysilane (KH550) was treated with reflux / mechanical stirring at 75°C for 10 hours to obtain ionized and positively charged amino-modified ZrO 2 Nanoparticle dispersion liquid, add GO dispersion liquid to it, make ZrO contained in the mixed solution 2 The mass ratio to GO is 60:1. GO contains a large number of carboxyl groups and hydroxyl groups are ionized and negatively charged. Ultrasonic / mechanical stirring treatment makes the positively and ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com