A kind of preparation method of water-soluble anionic polymer type heavy oil viscosity reducer

A technology of anionic polymer and viscosity reducer for heavy oil, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large amount of viscosity reducer for heavy oil, difficult demulsification, and poor salt resistance. , to achieve the effect of low production cost, simple preparation method and good viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

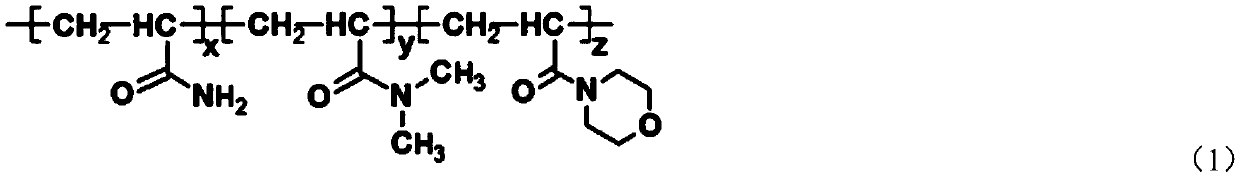

Method used

Image

Examples

Embodiment 1

[0051] The preparation and application of the water-soluble anionic polymer type heavy oil viscosity reducer include the following steps:

[0052] (1) Dissolve 2.756g of acrylamide, 2.161g of acryloyl morpholine, and 0.257g of N,N-dimethylacrylamide in 50g of water, and stir evenly; in this system, acrylamide, acryloyl morpholine, N,N- The molar ratio of dimethylacrylamide is 75:20:5, and the total mass fraction of acrylamide, acryloylmorpholine, and N,N-dimethylacrylamide is 10%;

[0053] (2) After the above system is deoxygenated and nitrogen passed, add 0.025g of initiator azobisisobutylamidine hydrochloride, and conduct free radical polymerization at 55°C for 10 hours to obtain component A; azobisisobutylamidine salt The mass fraction of acid salt is 0.5%;

[0054] (3) acrylamide 2.228g, sodium styrene sulfonate 2.777g, chain transfer agent mercaptoethylamine 0.050g are dissolved in 50g water to obtain a uniform solution; in this solution, the molar ratio of acrylamide an...

Embodiment 2

[0063] The preparation and application of the water-soluble anionic polymer type heavy oil viscosity reducer include the following steps:

[0064] (1) Dissolve 2.896g of acrylamide, 1.566g of acryloyl morpholine, and 0.538g of N,N-dimethylacrylamide in 50g of water, and stir evenly; in this system, acrylamide, acryloyl morpholine, N,N- The molar ratio of dimethylacrylamide is 75:15:10, and the total mass fraction of acrylamide, acryloylmorpholine, and N,N-dimethylacrylamide is 10%;

[0065] (2) After the above system is purged with nitrogen and deoxygenated, add 0.025g of initiator azobisisobutylamidine hydrochloride, and conduct free radical polymerization at 55°C for 10 hours to obtain component A; azobisisobutylamidine salt The mass fraction of acid salt is 0.5%;

[0066] (3) acrylamide 2.230g, sodium styrene sulfonate 2.775g, chain transfer agent mercaptoethylamine 0.050g are dissolved in 50g water to obtain a uniform solution; in this solution, the molar ratio of acrylam...

Embodiment 3

[0075] The preparation and application of the water-soluble anionic polymer type heavy oil viscosity reducer include the following steps:

[0076] (1) Dissolve 3.050 g of acrylamide, 1.100 g of acryloyl morpholine, and 0.851 g of N,N-dimethylacrylamide in 50 g of water, and stir evenly; in this system, acrylamide, acryloyl morpholine, N,N- The molar ratio of dimethylacrylamide is 75:10:15, and the total mass fraction of acrylamide, acryloylmorpholine, and N,N-dimethylacrylamide is 10%;

[0077] (2) After the above system is purged with nitrogen and deoxygenated, add 0.025g of initiator azobisisobutylamidine hydrochloride, and conduct free radical polymerization at 55°C for 10 hours to obtain component A; azobisisobutylamidine salt The mass fraction of acid salt is 0.5%;

[0078] (3) acrylamide 2.222g, sodium styrene sulfonate 2.771g, chain transfer agent mercaptoethylamine 0.050g are dissolved in 50g water to obtain a uniform solution; in this solution, the molar ratio of acr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com