Feedback 3d printer

A 3D printer and feedback technology, applied in the field of 3D printing, can solve problems such as the inability to use a variety of raw materials and the inability to perform high-pressure rapid jet printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

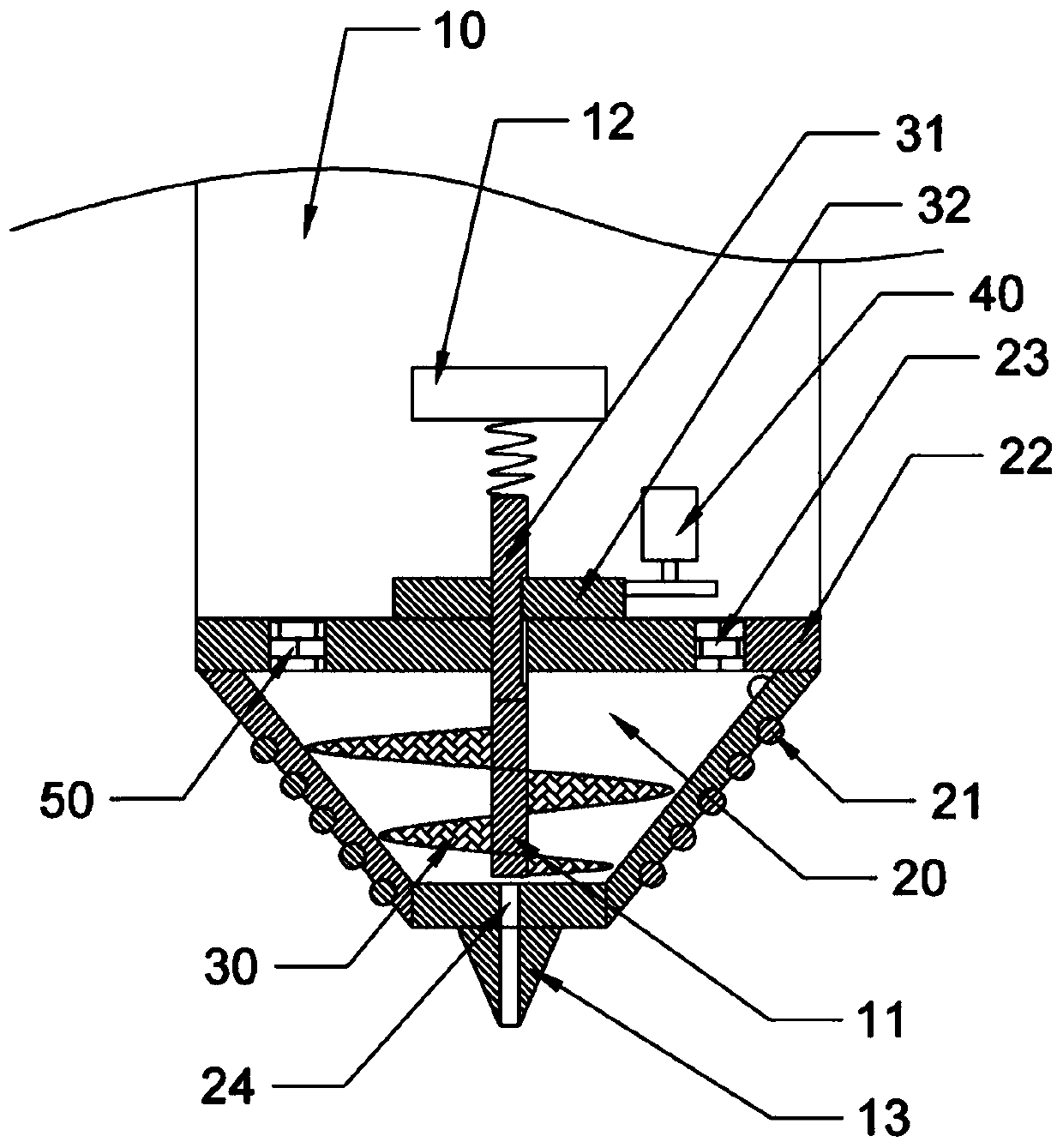

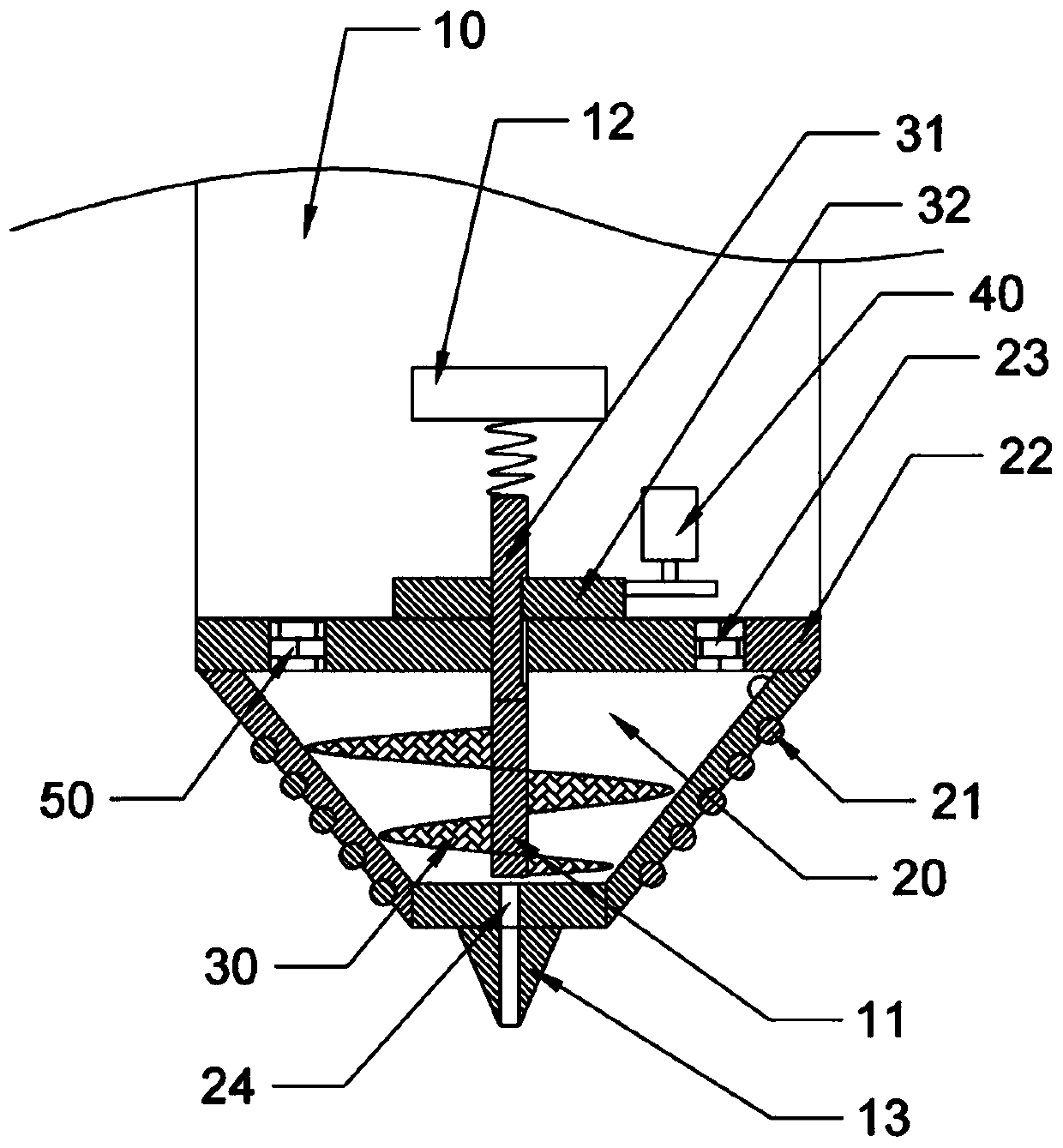

[0037] A feedback 3D printer, including a print head and a printer body for driving the print head to move in three-dimensional space;

[0038] print head (such as figure 1 shown) includes: a housing 10, a stirring shaft 11, an electromagnet 12, a nozzle 13, a temperature sensor and a controller; the material of the housing 10 is plastic. Specific spatial positions: from top to bottom are the electromagnet 12, the stirring shaft 11, and the nozzle 13.

[0039] The casing 10 is provided with a hot-melt part made of plastic material. The hot-melt part is provided with a conical hot-melt cavity 20 with a large upper part and a smaller lower part. The hot-melt part is covered with an electromagnetic heater 21. Above the hot-melt cavity 20 A sealing cover 22 is hinged, and a pressure relief valve 23 is arranged on the sealing cover 22 , and a material injection port 24 is opened at the bottom of the hot-melt part.

[0040] The stirring shaft 11 is welded with a spiral stirring bl...

Embodiment 2

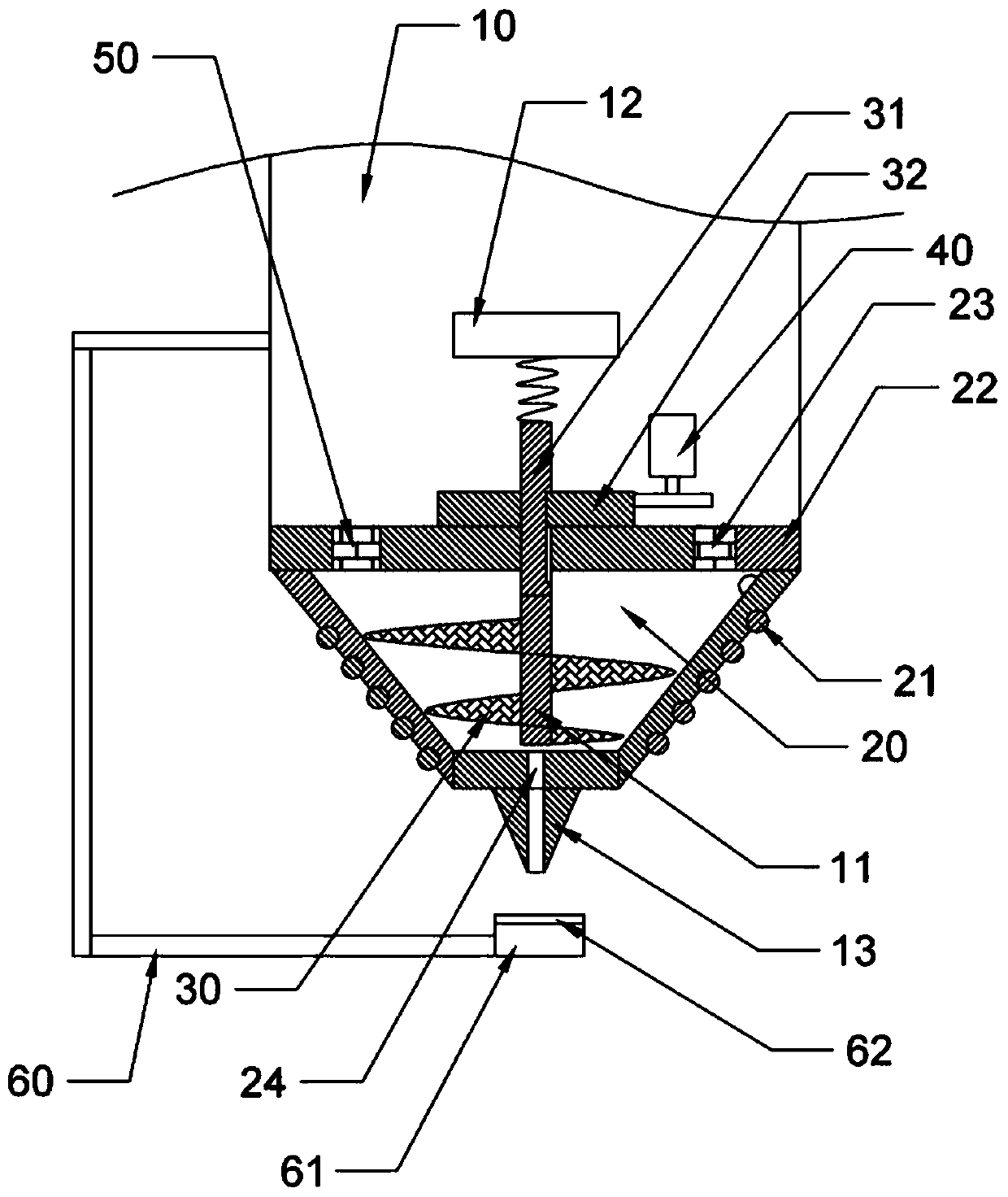

[0049] Compared with Embodiment 1, the only difference is that it also includes an air cooler 61 (such as figure 2 As shown), a bracket 60 is provided between the air cooler 61 and the shell, the air cooler 61 is located below the nozzle 13, and a pressure sensitive sensor 62 is arranged on the upper surface of the air cooler 61, and the pressure sensitive sensor 62 is connected to the controller signal.

[0050] Specific use: The raw material is cooled as soon as it comes out of the nozzle 13. When printing some bottom is a cavity and the upper part is a suspended structure (such as the roof of a house model), this design can speed up cooling and prevent collapse. . When there is a collapse, the raw material will fall on the surface of the air cooler 61, and the pressure sensitive sensor 62 can detect this signal and feed back to the controller. After the existing 3D printer fails to print, the print head will still move along the preset trajectory, resulting in waste of ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com