Laser sintering scanning method

A scanning method and laser sintering technology, applied in the field of metal additive manufacturing, can solve problems such as cracking, detachment from the substrate, and scrapping of parts that fail to print, and achieve the effect of taking into account scanning efficiency and reducing thermal stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

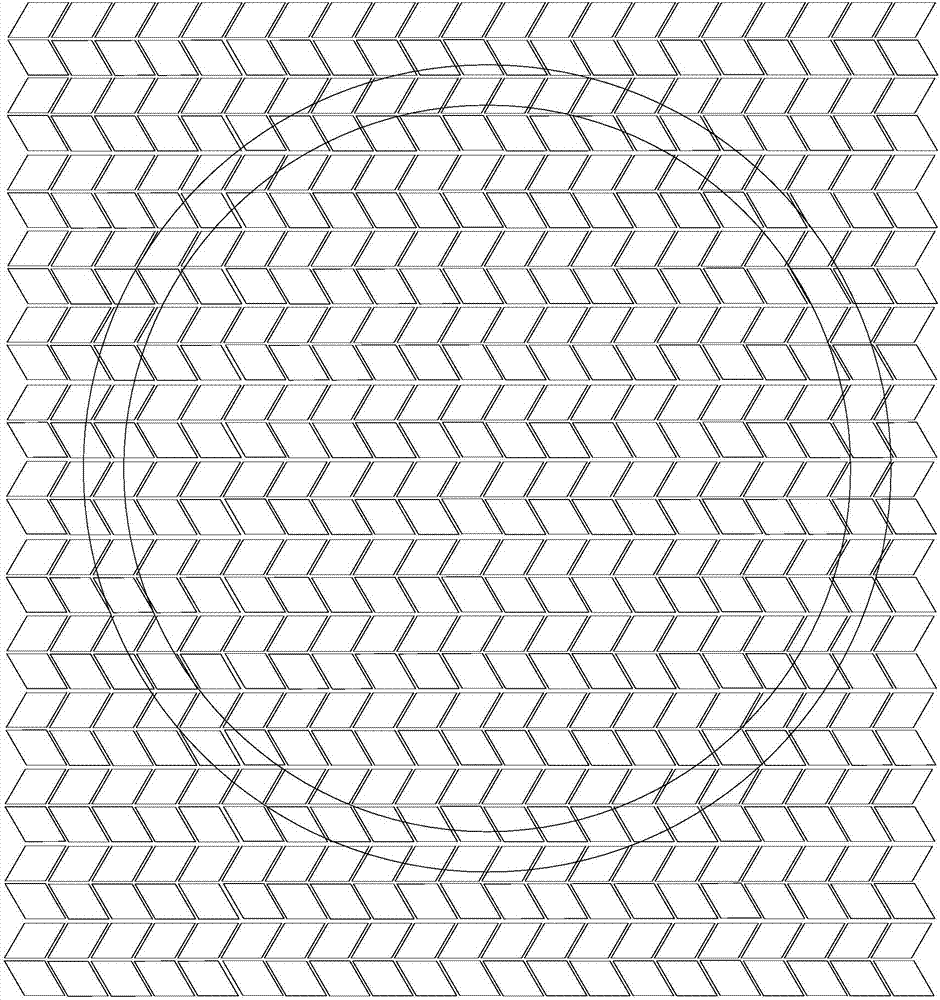

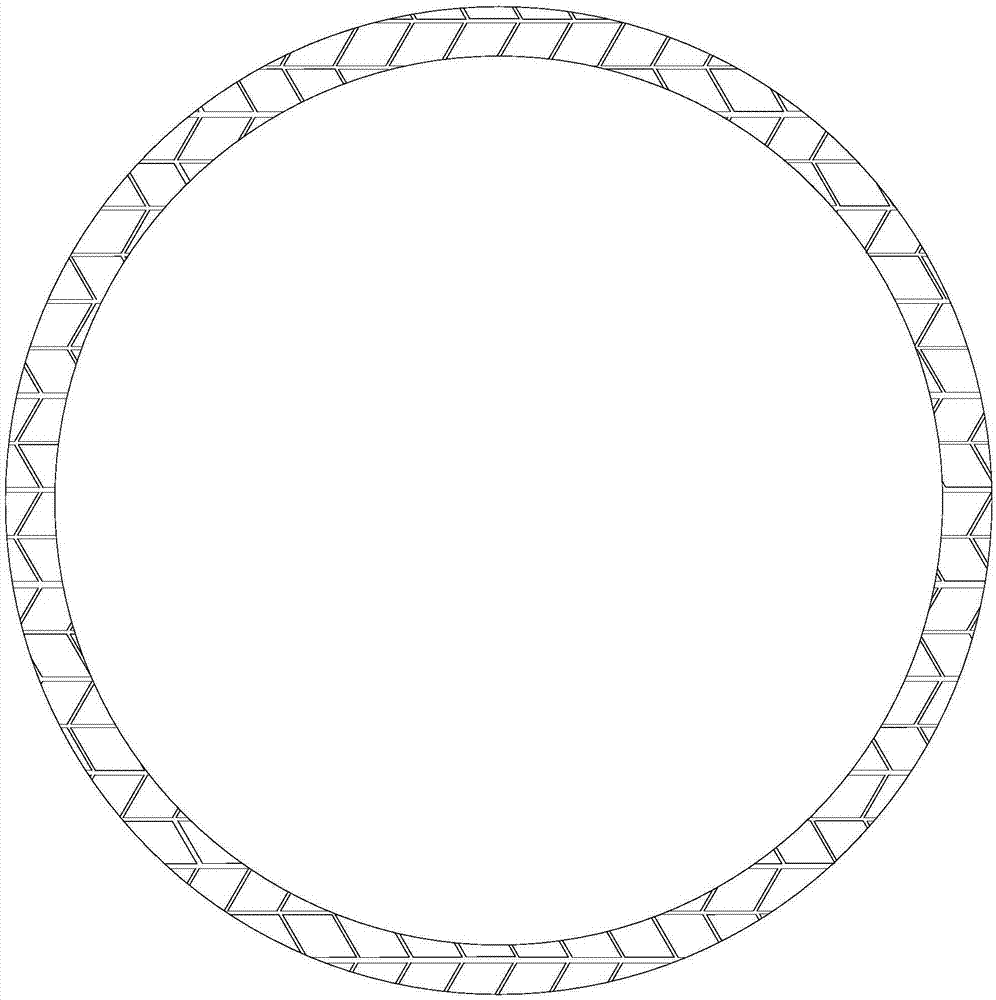

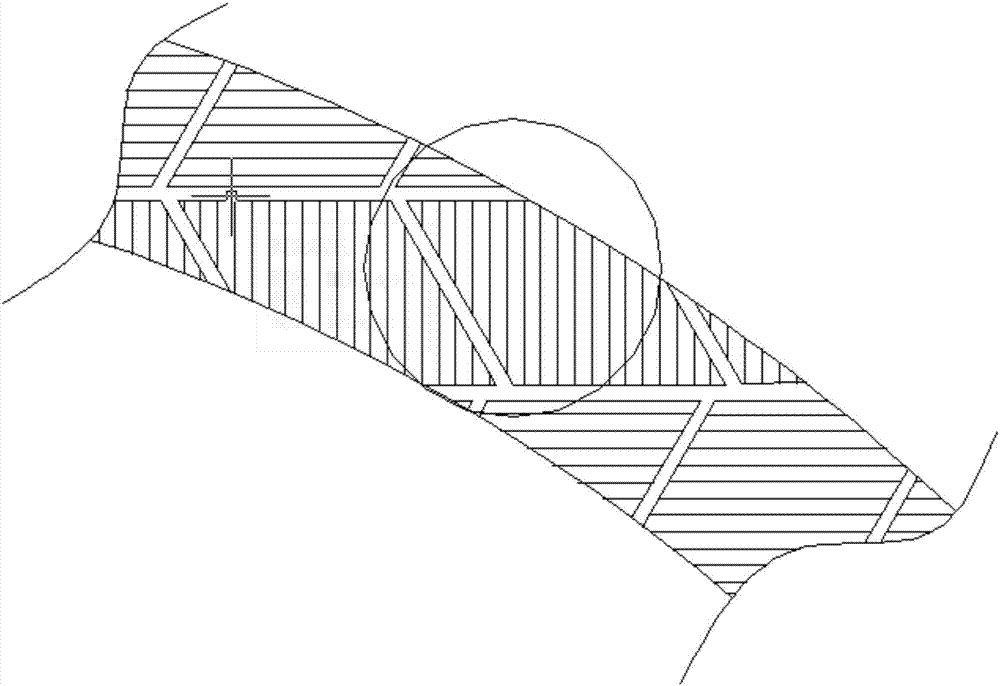

[0047] In this embodiment, the workpiece to be manufactured has a maximum cross-sectional diameter of For a circular thin-walled part with a wall thickness of 10mm, according to the cross-sectional information of the workpiece, the workpiece area is first divided into several partitioned graphics, and the partitioned graphics are grid-like parallelograms or irregular graphics with a side length of 10mm. The gap H between adjacent partition patterns takes a positive value of 0.7mm.

[0048] The laser sintering scanning method adopted in this embodiment includes the following main steps:

[0049] Step 1: Treat the irregular graphics of the boundary in the partition as a partition parallelogram, and then according to the shape and size of the workpiece, start with the partition graphics on one side of the workpiece, and sequentially scan the partition graphics that are parallel to each other continuous scan;

[0050] Step 2: Then use the infrared thermal imager to collect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com