Treating method for improving steel toughness

A treatment method and steel technology, applied in the production of dual-phase steel products, can solve the problems of poor low-temperature impact toughness and failure to meet the use requirements, and achieve the effects of reducing plasticity and toughness, preventing precipitation, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

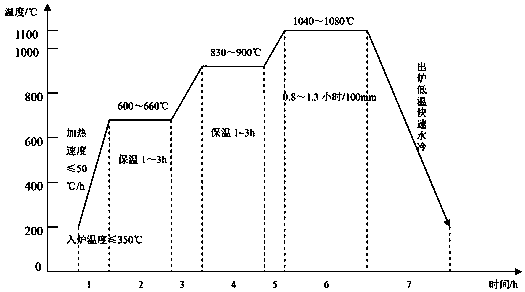

[0017] The treatment method to improve the toughness of steel is as follows:

[0018] 1) After the steel is forged, load the furnace under the condition that the furnace temperature is not higher than 350°C, and perform two preheating;

[0019] 2) The temperature of the first preheating is 600°C, the heating rate is 0<50°C / h, and the temperature is kept for 1h; the temperature of the second preheating is 830°C, the temperature is kept for 1h, and then solid solution treatment is carried out;

[0020] 3) The solid solution temperature is 1040°C, the holding time is 0.8 hours / 100mm, and then cooled;

[0021] 4) Put it into clean water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 4 seconds / mm.

[0022] In the step 4), in order to control the temperature of the clear water, the clear water is continuously injected at a speed of 38 tons / hour.

Embodiment 2

[0024] The treatment method to improve the toughness of steel is as follows:

[0025] 1) After the steel is forged, load the furnace under the condition that the furnace temperature is not higher than 350°C, and perform two preheating;

[0026] 2) The temperature of the first preheating is 660°C, the heating rate is 0<50°C / h, and the temperature is kept for 3 hours; the temperature of the second preheating is 900°C, the temperature is kept for 3 hours, and then solid solution treatment is carried out;

[0027] 3) The solid solution temperature is 1080°C, the holding time is 1.3 hours / 100mm, and then cooled;

[0028] 4) Put it into clean water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 6 seconds / mm.

[0029] In the step 4), in order to control the temperature of the clear water, the clear water is continuously injected at a speed of 40 tons / hour.

Embodiment 3

[0031] The treatment method to improve the toughness of steel is as follows:

[0032] 1) After the steel is forged, load the furnace under the condition that the furnace temperature is not higher than 350°C, and perform two preheating;

[0033] 2) The temperature for the first preheating is 630°C, the heating rate is 0<50°C / h, and the temperature is kept for 2 hours; the temperature for the second preheating is 870°C, the temperature is kept for 1 hour, and then solid solution treatment is performed;

[0034] 3) The solid solution temperature is 1060°C, the holding time is 1 hour / 100mm, and then cooled;

[0035] 4) Put it into clean water with an initial temperature of less than 10°C, and keep it for 20 minutes at a cooling rate of 5 s / mm.

[0036] In the step 4), in order to control the temperature of the clear water, the clear water is continuously injected at a speed of 39 tons / hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com