3D printing modified waterborne polyurethane and preparation method thereof

A water-based polyurethane and 3D printing technology, which is applied in the field of polymer materials, can solve the problems of flower oil, edge retention, slow and weak 3D effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

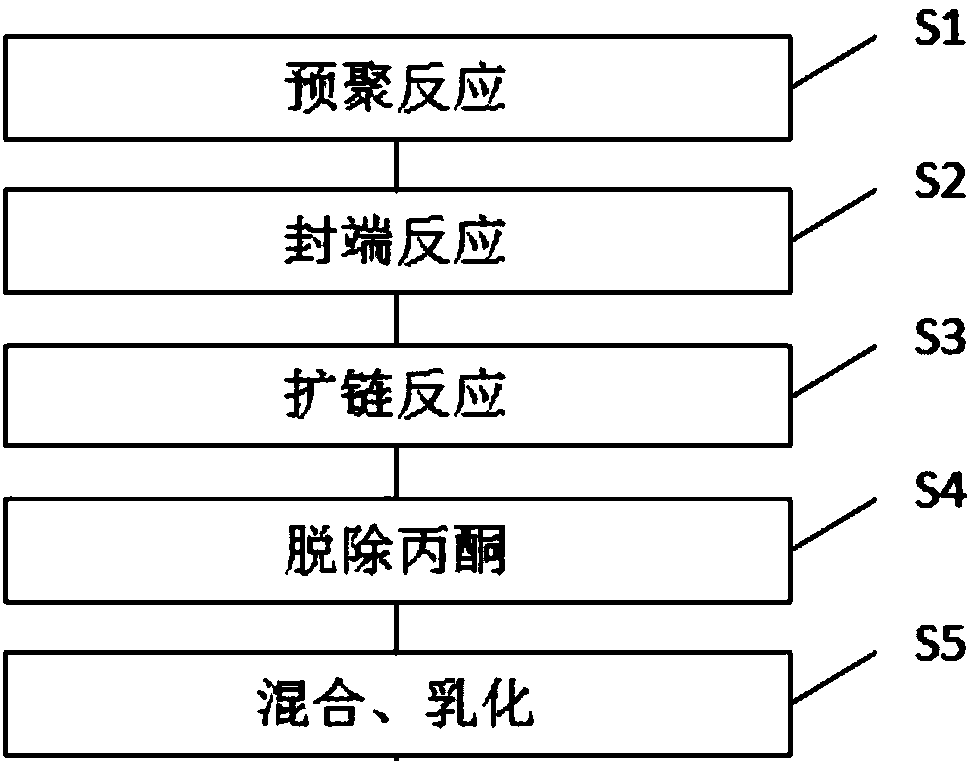

[0033] refer to figure 1 , the second aspect of the embodiment of the present application shows a preparation method of 3D printing modified water-based polyurethane, comprising the following steps:

[0034] S1 prepolymerization reaction: dehydration of polyol, and then prepolymerization reaction with isocyanate at a mass ratio of 1:2 to obtain polyurethane prepolymer;

[0035] S2 capping reaction: carry out capping reaction with described polyurethane prepolymer and small molecular diol with the mass ratio of 1:2, make the polyurethane of capping;

[0036] S3 chain extension reaction: add acetone to dilute and emulsify the blocked polyurethane, then add an amine chain extender to carry out the chain extension reaction to obtain a polyurethane dispersion;

[0037] S4 removes acetone: removes acetone in the polyurethane dispersion to obtain the water-based polyurethane;

[0038] S5 Mixing and emulsification: put the water-based polyurethane, silane coupling agent and nano-sil...

Embodiment 1

[0049] S1 prepolymerization reaction: dehydrate polyol at 150°C, and then prepolymerize with isocyanate at 100°C at a mass ratio of 1:2 to obtain a polyurethane prepolymer;

[0050] S2 capping reaction: the polyurethane prepolymer and the small molecule diol are subjected to a capping reaction at a mass ratio of 1:2 at 110° C. to obtain a capped polyurethane;

[0051] S3 chain extension reaction: add acetone to dilute and emulsify the end-capped polyurethane, cool down to 25°C, then add methylpentamethylenediamine chain extender to carry out chain extension reaction at 25°C to obtain a polyurethane dispersion;

[0052] S4 removes acetone: removes acetone in the polyurethane dispersion to obtain the water-based polyurethane with a solid content of 65%;

[0053] S5 Mixing and emulsification: put the water-based polyurethane, silane coupling agent and nano-silica into the stirring tank at a mass ratio of 90:7:3 to fully stir and mix. The rotating speed of the stirring tank is 150...

Embodiment 2

[0055] S1 prepolymerization reaction: dehydrate polyol at 120°C, and then carry out prepolymerization reaction with isocyanate at 80°C at a mass ratio of 1:2 to obtain polyurethane prepolymer;

[0056] S2 capping reaction: the polyurethane prepolymer and the small molecule diol are subjected to a capping reaction at a mass ratio of 1:2 at 80° C. to obtain a capped polyurethane;

[0057] S3 chain extension reaction: add acetone to dilute and emulsify the end-capped polyurethane, cool down to 25°C, then add methylpentamethylenediamine chain extender to carry out chain extension reaction at 25°C to obtain a polyurethane dispersion;

[0058] S4 removes acetone: removes the acetone in the polyurethane dispersion to obtain the water-based polyurethane with a solid content of 60%;

[0059] S5 Mixing and emulsification: put the water-based polyurethane, silane coupling agent and nano-silica in a mass ratio of 91:7:2 into a stirring tank and fully stir and mix. The rotation speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com