Protecting die for double-glass assembly

A technology of double-glass components and molds, which is applied to electrical components, semiconductor devices, lamination, etc., can solve the problems of severe stress at the four corners, lack of glue at the four corners, and easy deformation of the glass, achieving a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

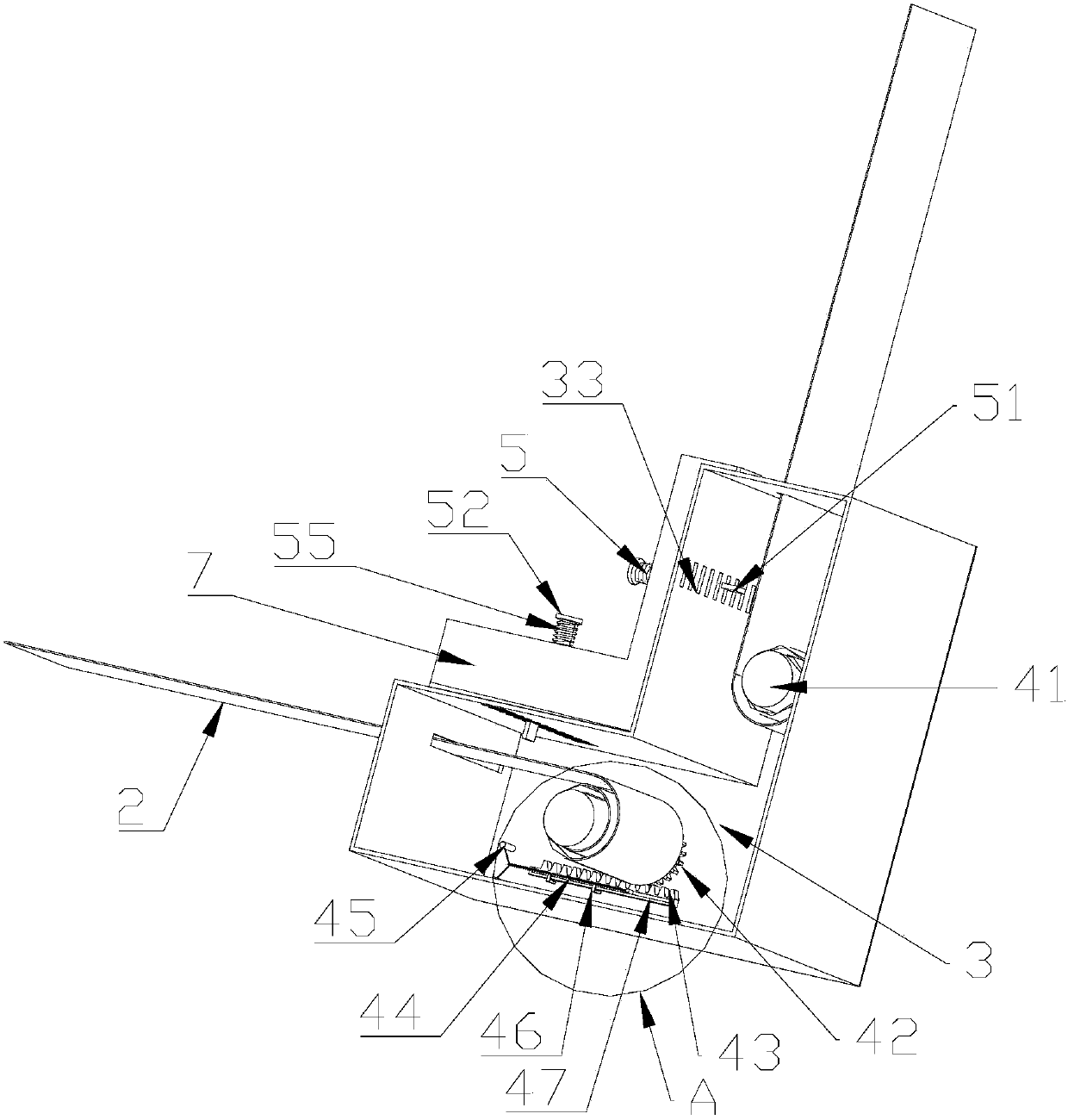

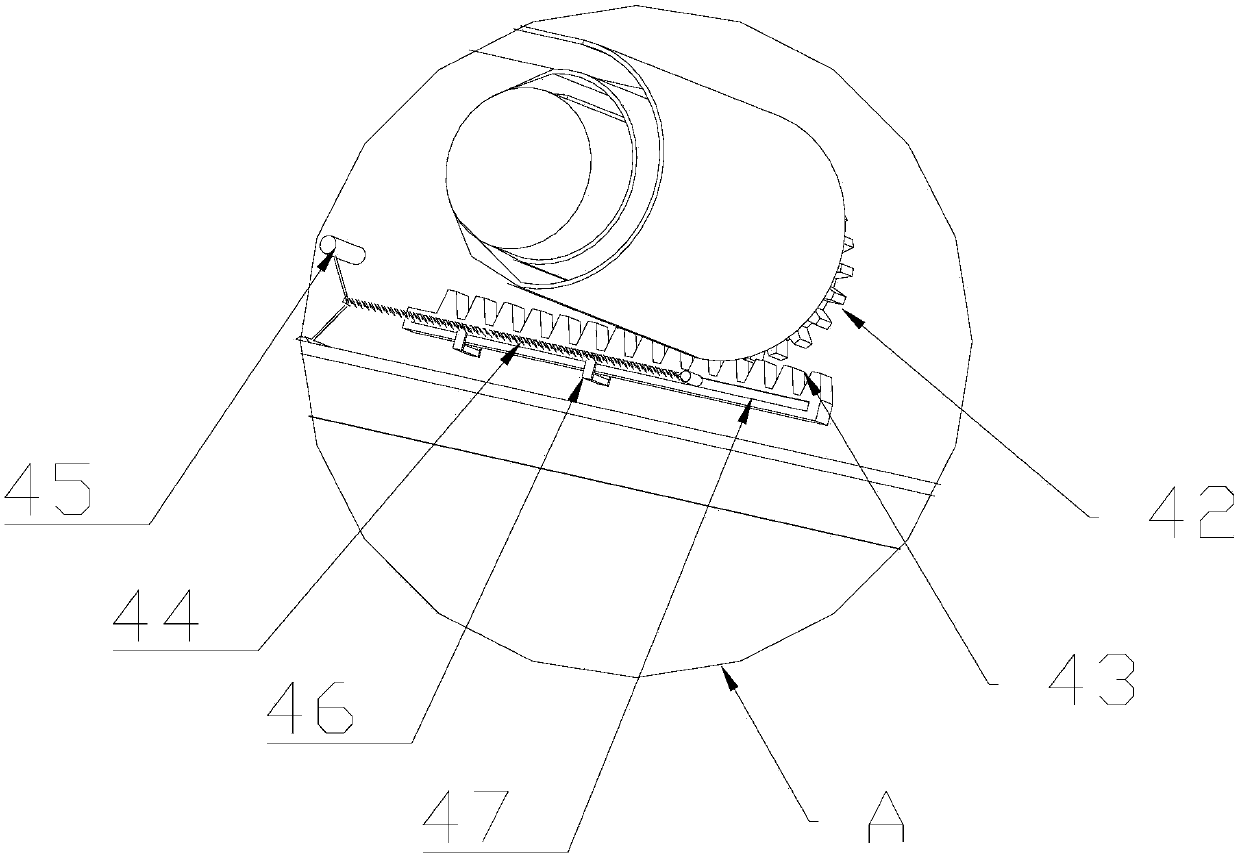

[0041] Embodiment 1, one end of the insertion rod 5 is connected to the inserting plate 51, the other end of the insertion rod 5 passes through the movable wing 7 to connect to the limit plate 52, the insertion rod 5 is sleeved with a buffer spring 55, and the buffer One end of the spring 55 is connected with the limiting plate 52 , and the other end of the buffer spring 55 is connected with the movable wing 7 . Squeeze the buffer spring 55 to completely penetrate the inserting plate 51 in the connecting hole 33, then turn the inserting rod 5 so that the inserting plate 51 crosses the connecting hole 33, loosen the inserting rod 5, and under the reset tension state of the buffer spring 55 , so that the movable wing 7 is fastened to the second side wall 32 of the cavity 3 .

Embodiment 2

[0042] Embodiment 2, one end of the insertion rod 5 is connected to the insertion plate 51, and the other end of the insertion rod 5 passes through the movable wing 7 to connect to the limit plate 52; the insertion rod 5 includes a front end rod 53 and a rear end rod 54, The diameter of the front end rod 53 connected with the flashboard 51 is set to be the same as the thickness of the flashboard 51 ; Turn the insertion rod 5 to make the rear end rod 54 and the movable wing 7 spirally move, so that the front end rod 53 extends out of the movable wing 7 to a longer length, so that the insertion plate 51 completely penetrates the connecting hole 33, and then rotate the insertion rod in the opposite direction 5. Make the movable flap 7 and the second side wall 32 seamlessly fastened, and the inserting plate 51 crosses the connection hole 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com