Plate-and-strip online heating device used in rolling process of magnesium alloy

A heating device, induction heating device technology, applied in the direction of metal rolling, induction heating, lighting and heating equipment, etc., can solve problems such as plate rolling failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

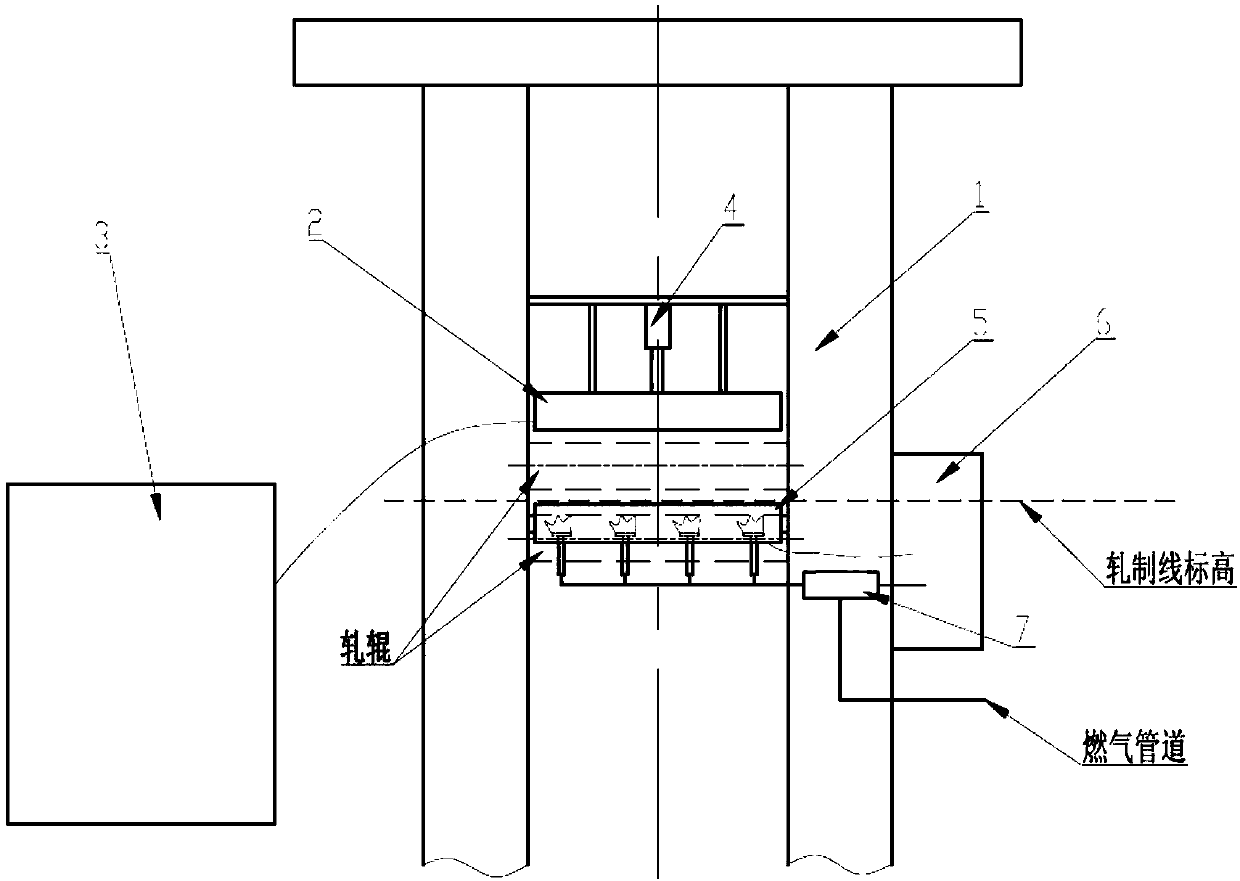

[0043] Assuming that the geometric size of the magnesium alloy plate to be rolled is 1600×4mm, the traveling speed is 1000mm / min, and the temperature is increased from 100°C to 220°C after passing through the online heating device, the design and use method of the present invention will be described below through specific equipment specifications and operating steps .

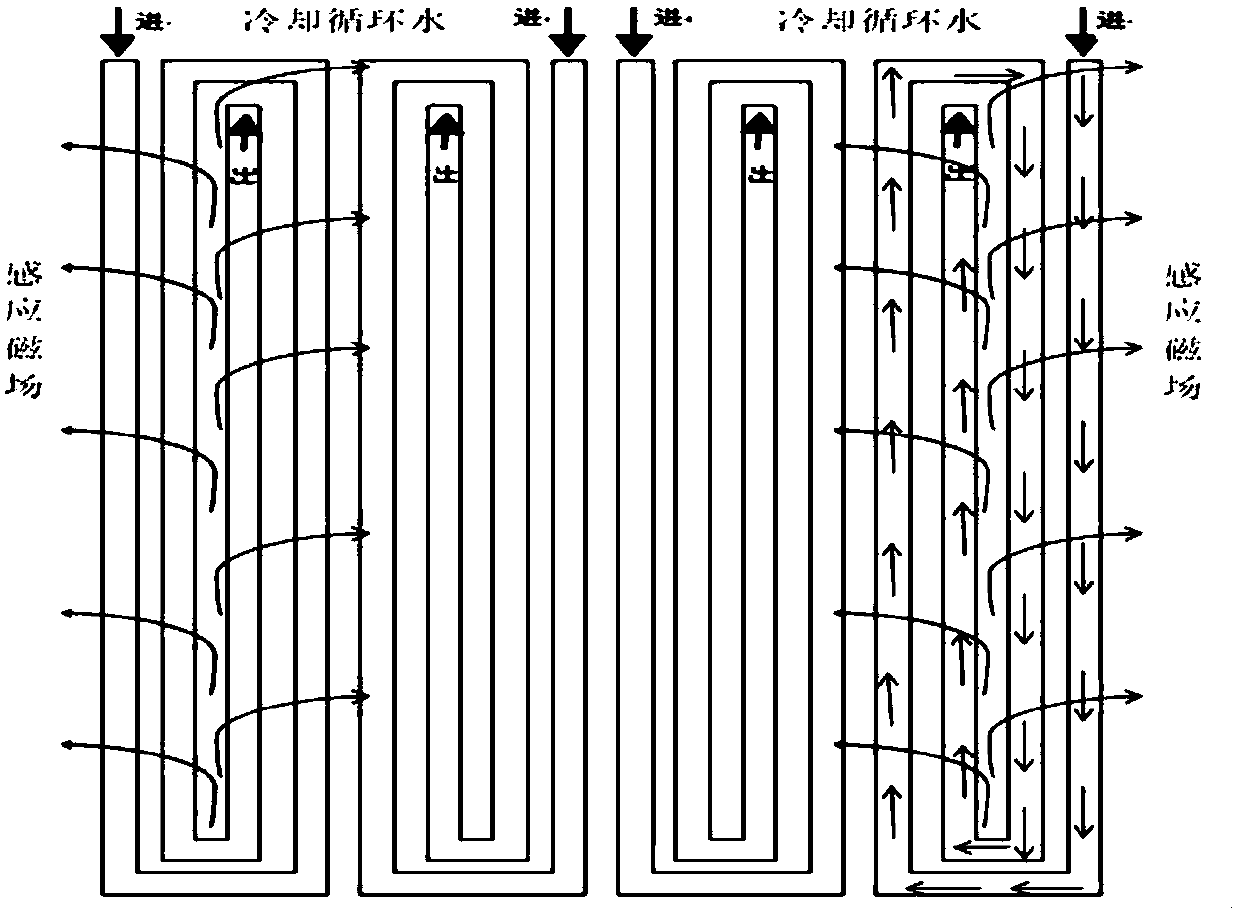

[0044] The induction device adopts a thyristor-type medium-frequency induction heating device, the inverter model is GPS / 500 / 1S, and it is cooled by water cooling with a pressure of 0.1-0.2 MPa. The inductor adopts a flat multi-layer type and adds a magnetic yoke device inside it. figure 2 , The geometrical size of the sensor is 1900*750*400, and the maximum power of the power supply is 800kW. The induction heating furnace body adopts 20mm phenolic glass silk board without magnetism, and there is a hook device on it. Two screw rods with a diameter of 40mm are connected to the top of the box, and a motor is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com