A kind of preparation method of biomass alkaline fuel cell anode

A fuel cell, biomass technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low energy density, low electrode reuse rate, low anode catalyst utilization, etc., and achieve high surface area/volume ratio, high The effect of electrocatalytic oxidation of glucose activity and anode performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

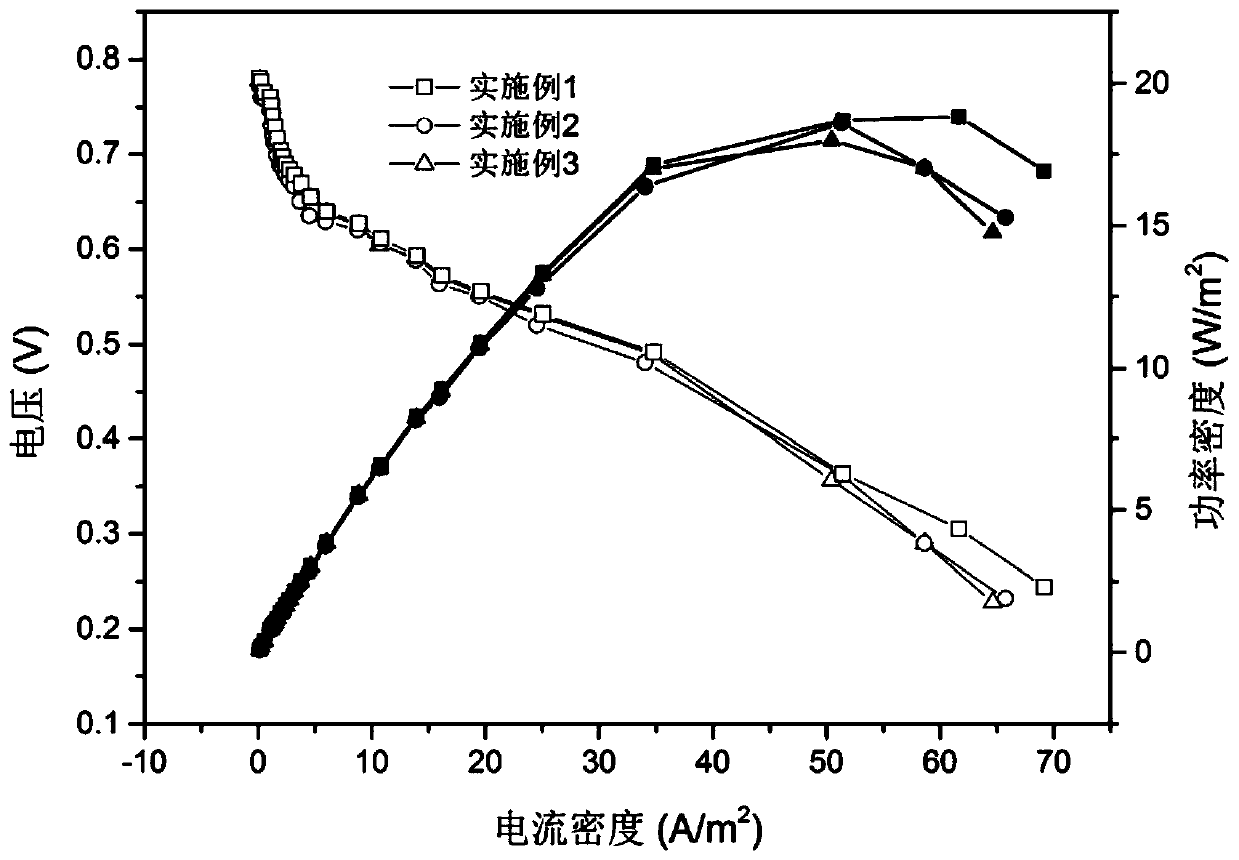

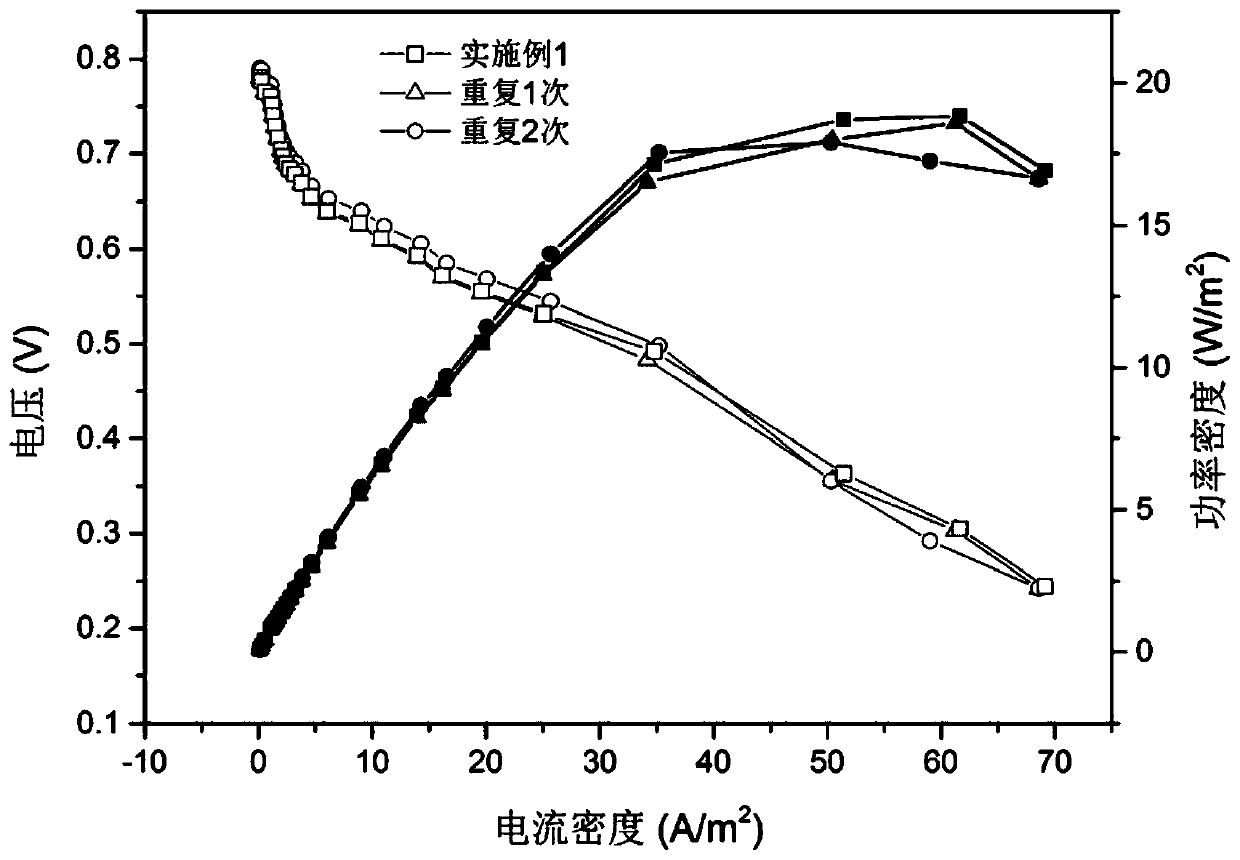

Embodiment 1

[0028] (1) Cut out a circular foamed nickel mesh with a diameter of 3.5 cm, put the cut foamed nickel mesh into acetone solution (analytical pure), absolute ethanol (analytical pure) and distilled water for ultrasonic cleaning for 15 minutes, and then put it into 60 ℃ oven dry 2h, set aside.

[0029] (2) Prepare the electrolyte for electrodeposition, which is NiSO 4 10mM, CuSO 4 20mM, CoSO 4 5mM and nicotinamide 1mM mixed solution, use dilute sulfuric acid to adjust the pH of the electrodeposition solution to 4;

[0030] Put the foamed nickel mesh vertically into the electrodeposition cell as the working electrode, the platinum electrode as the counter electrode, and the calomel electrode as the reference electrode; add electrolyte to the electrodeposition cell until the foamed nickel mesh is completely submerged, the deposition voltage is 1V, and the foam Deposit on one side of the nickel mesh for 600s, replace the electrolyte and deposit the other side of the foamed ni...

Embodiment 2

[0038] (1) Cut out a circular foamed nickel mesh with a diameter of 3.5 cm, put the cut foamed nickel mesh into acetone solution (analytical pure), absolute ethanol (analytical pure) and distilled water for ultrasonic cleaning for 15 minutes, and then put it into 60 ℃ oven dry 2h, set aside.

[0039] (2) Prepare the electrolyte for electrodeposition, which is NiSO 4 10mM, CuSO 4 20mM, CoSO 4 5mM and nicotinamide 1mM mixed solution, use dilute sulfuric acid to adjust the pH of the electrodeposition solution to 4;

[0040] Put the foamed nickel mesh vertically into the electrodeposition cell as the working electrode, the platinum electrode as the counter electrode, and the calomel electrode as the reference electrode; add electrolyte to the electrodeposition cell until the foamed nickel mesh is completely submerged, the deposition voltage is 3V, and the foam Deposit on one side of the nickel mesh for 500s, replace the electrolyte and deposit the other side of the foamed ni...

Embodiment 3

[0048] (1) Cut out a circular foamed nickel mesh with a diameter of 3.5 cm, put the cut foamed nickel mesh into acetone solution (analytical pure), absolute ethanol (analytical pure) and distilled water for ultrasonic cleaning for 15 minutes, and then put it into 60 ℃ oven dry 2h, set aside.

[0049] (2) Prepare the electrolyte for electrodeposition, which is NiSO 4 10mM, CuSO 4 20mM, CoSO 4 5mM and nicotinamide 1mM mixed solution, use dilute sulfuric acid to adjust the pH of the electrodeposition solution to 4;

[0050] Put the foamed nickel mesh vertically into the electrodeposition cell as the working electrode, the platinum electrode as the counter electrode, and the calomel electrode as the reference electrode; add electrolyte to the electrodeposition cell until the foamed nickel mesh is completely submerged, the deposition voltage is 5V, and the foam Deposit on one side of the nickel mesh for 800s, replace the electrolyte and deposit the other side of the foamed ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com