A Modeling Method of Switched Reluctance Motor Considering Instantaneous Iron Loss

A technology of switched reluctance motor and modeling method, which is applied in CAD numerical modeling, electrical digital data processing, computer-aided design, etc., can solve the problems of the dynamic performance impact of switched reluctance motor, the large specific gravity, the large iron consumption ratio, etc. , to achieve the effect of improving dynamic simulation accuracy, improving accuracy and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The switching reluctance motor modeling method considering instantaneous iron loss of the present invention comprises the following steps:

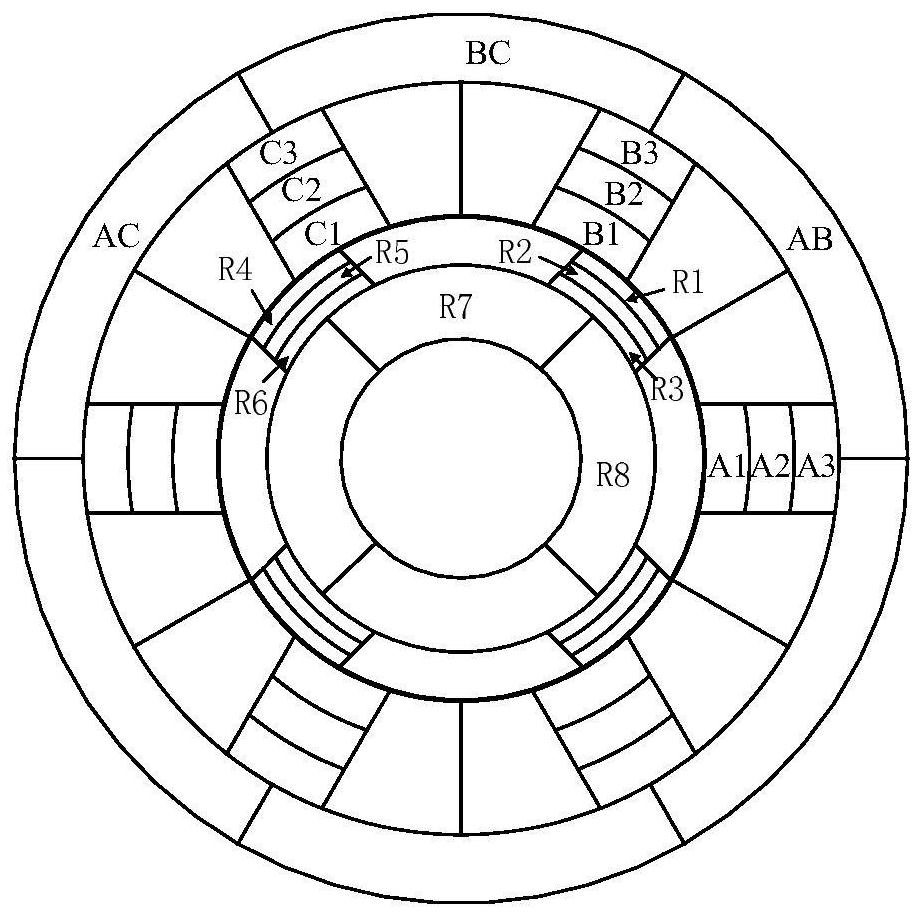

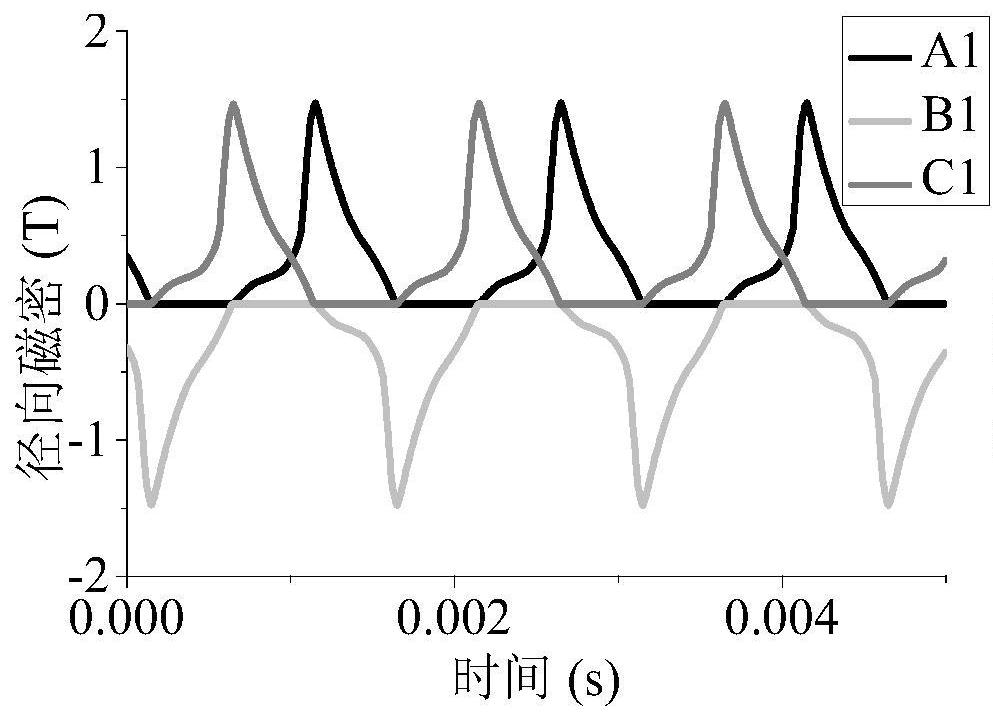

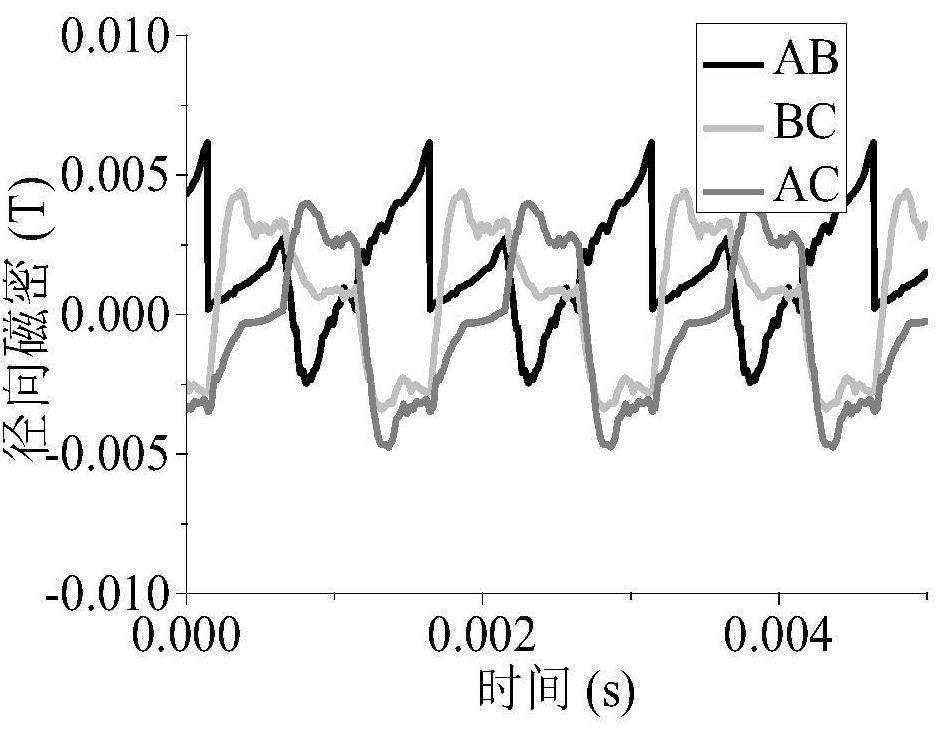

[0058]a. First, establish the finite element model of the motor through the finite element analysis software, analyze the electromagnetic field distribution of the motor, and divide the iron core part of the motor according to the distribution of the electromagnetic field of the motor. The radial direction is divided into three areas, the rotor pole is divided into three areas along the radial direction, the stator yoke between the two-phase stator poles, and the yoke area between the rotor poles, and each characteristic area is selected 1 feature point, the static flux density data of each feature point changing with the rotor position and current is obtained, and the equivalent magnetic circuit analysis method is used to analyze the flux density distribution and change trend of the motor, and the static flux density and each area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com