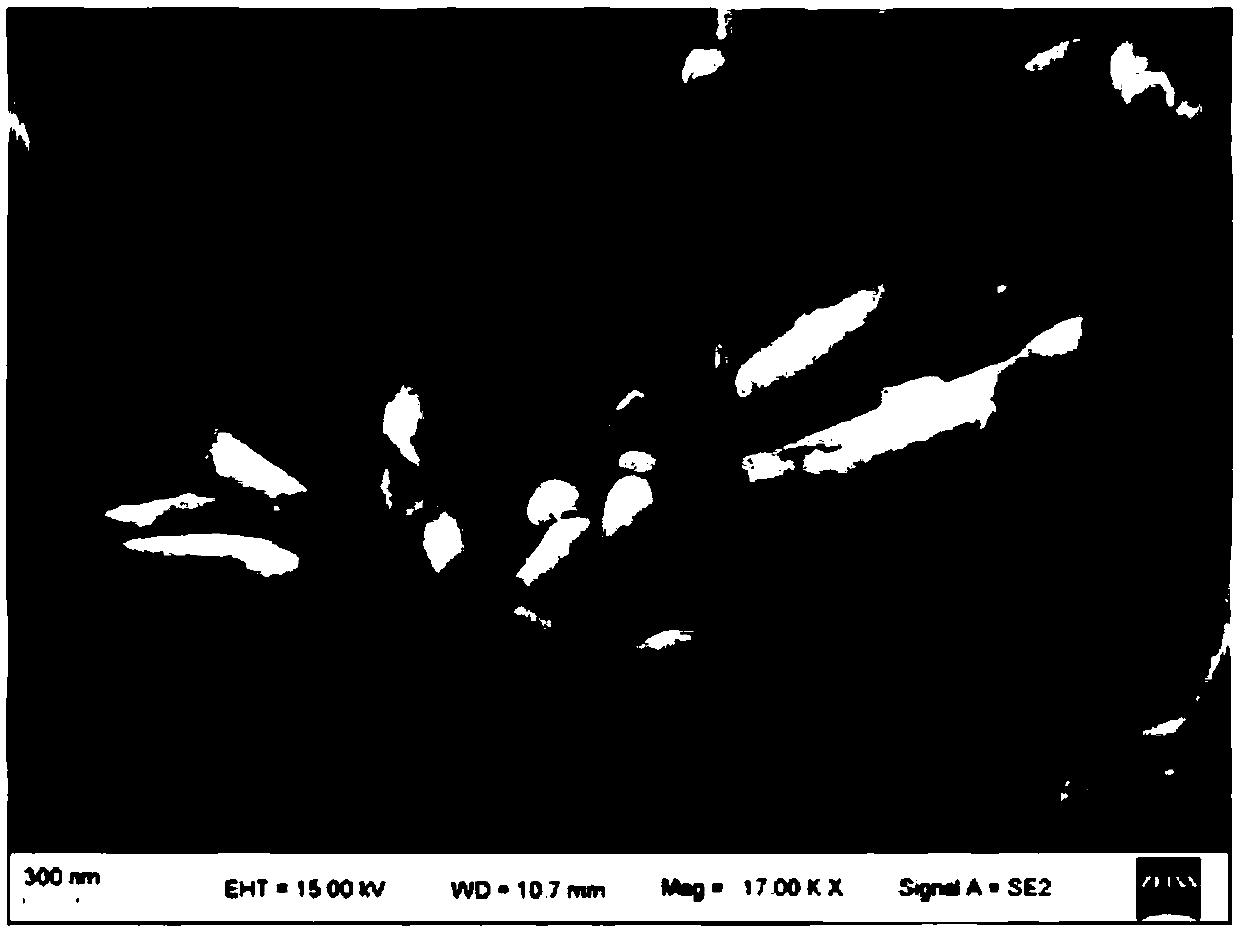

Preparation method of lanthanum cuprate nano adsorption material

A nano-adsorption material, lanthanum cuprate technology, applied in the direction of nanotechnology, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of high impurity content in products, high synthesis temperature, uncontrollable reaction conditions, etc., and achieve catalytic Excellent effect, large aspect ratio and specific surface area, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

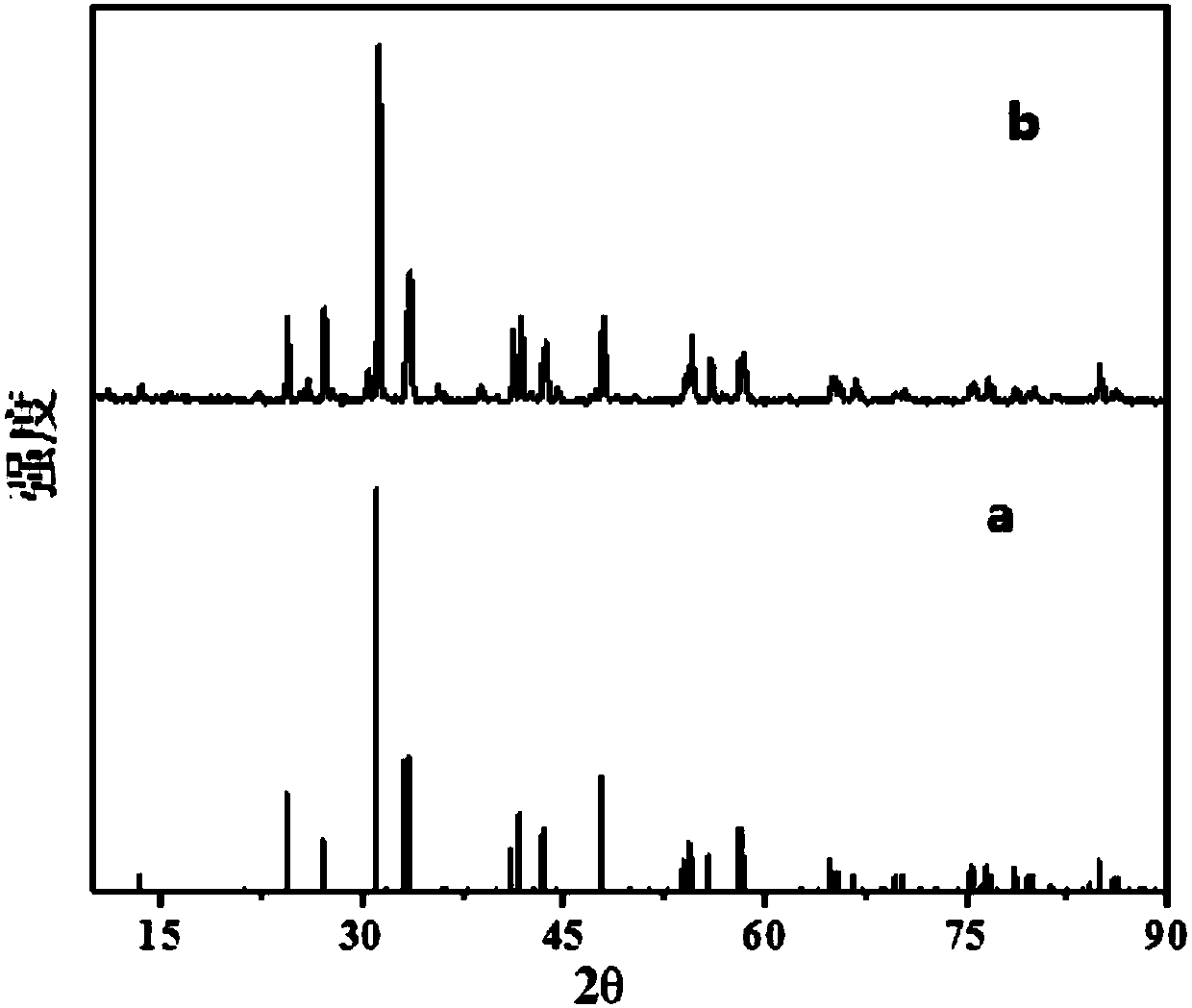

Embodiment 1

[0036] (1) According to lanthanum cuprate La 2 CuO 4 In the stoichiometric ratio of Cu and La, weigh 2mmol copper acetate and 4mmol lanthanum acetate and dissolve them in deionized water. The volume of deionized water is 6 times the total molar mass of copper acetate and lanthanum acetate and mix evenly to obtain solution A;

[0037] (2) Weigh 2g sodium hydroxide and dissolve in 20g ethanol solution, adjust pH=10 to obtain solution B;

[0038] (3) Slowly pour solution B into solution A, add 3g of polyethylene glycol and 1g of dimethylglyoxime, stir for 30min, and the rotor speed is 600r / min, and prepare solution C;

[0039] (4) Apply positive and negative direct current electric fields, the voltage of positive and negative direct current electric fields is ±5000V, and the reaction time is 30min; add ±5V alternating current electric fields to control the direction of its current and form rectangular tooth-shaped electric waves; let the solution C stand still, and then Solutio...

Embodiment 2

[0043] (1) According to lanthanum cuprate La 2 CuO 4 In the stoichiometric ratio of Cu and La, weigh 2mmol copper nitrate and 4mmol lanthanum acetate and dissolve them in deionized water. The volume of deionized water used is 6 times the total molar mass of copper nitrate and lanthanum acetate and mixed evenly to obtain solution A;

[0044] (2) Weigh 1.5g potassium hydroxide and dissolve in 20g ethanol solution, adjust pH=10.5 to obtain solution B;

[0045] (3) Slowly pour solution B into solution A, add 2 g of polyethylene glycol and 1 g of dimethylglyoxime, stir magnetically for 35 min, and the rotor speed is 700 r / min, and prepare solution C;

[0046] (4) Apply positive and negative direct current electric fields, the voltage of the positive and negative direct current electric fields is ±3000V, and the reaction time is 60min; add ±3V alternating current electric fields to control the current direction and form rectangular tooth-shaped electric waves; let the solution C st...

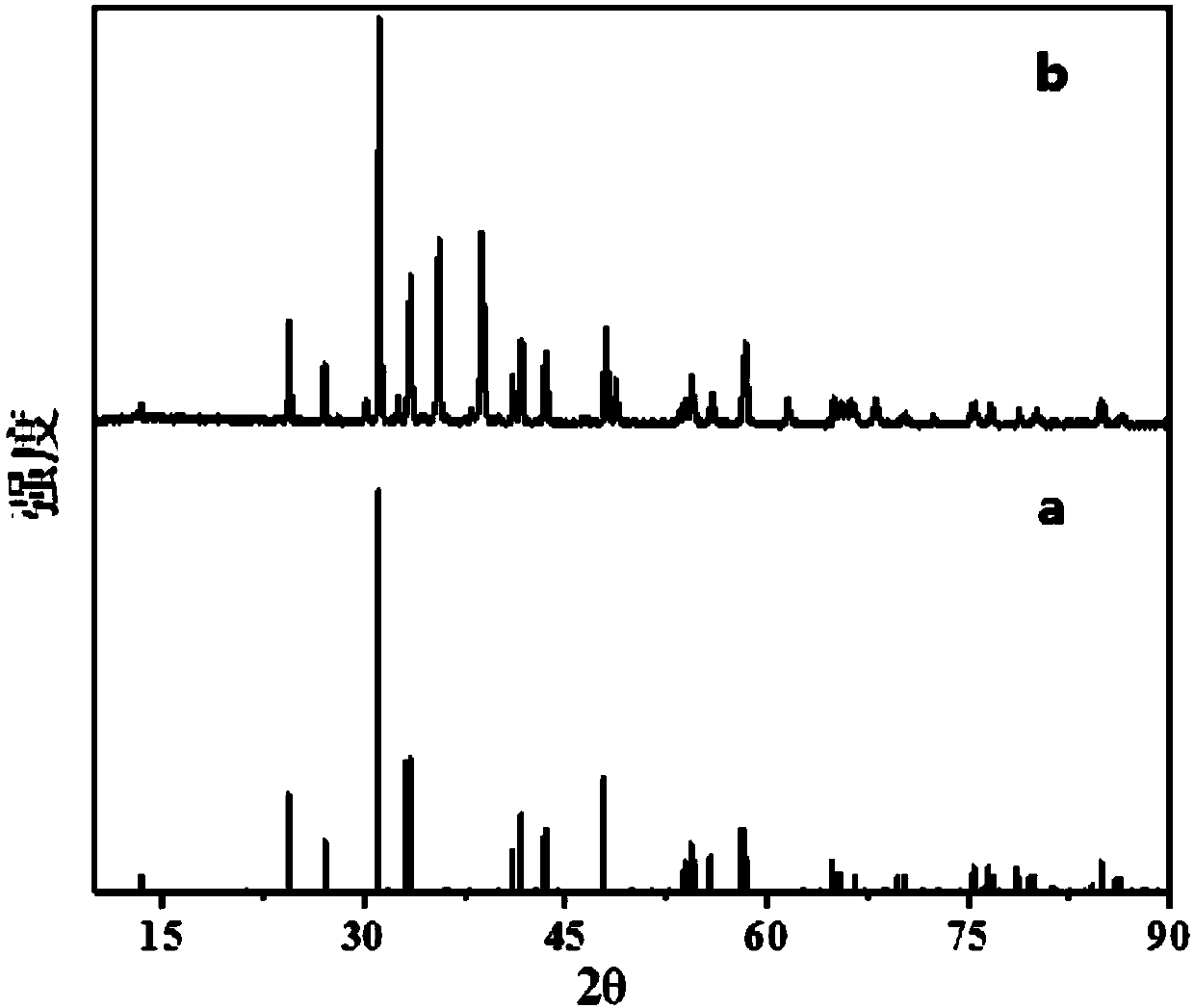

Embodiment 3

[0050] (1) According to lanthanum cuprate La 2 CuO 4 In the stoichiometric ratio of Cu and La, take 2mmol copper acetate and 4mmol lanthanum carbonate and dissolve them in deionized water. The volume of deionized water used is 7 times the total molar mass of copper acetate and lanthanum carbonate and mixed evenly to obtain solution A;

[0051] (2) Weigh 2.5g of triethylamine and dissolve it in 25g of ethanol solution, adjust pH=10 to obtain solution B;

[0052] (3) Slowly pour solution B into solution A, add 2 g of polyethylene glycol and 1 g of dimethylglyoxime, stir magnetically for 30 min, and the rotor speed is 700 r / min, and prepare solution C;

[0053] (4) Apply positive and negative direct current electric fields, the voltage of positive and negative direct current electric fields is ±2000V, and the reaction time is 60min; add ±5V alternating current electric fields to control the direction of its current to form rectangular tooth-shaped electric waves; let the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com