Preparation method of nano calcium hydroxide for root canal filling material

A calcium hydroxide, root canal filling technology, applied in nanotechnology for material and surface science, calcium/strontium/barium oxide/hydroxide, nanotechnology, etc., can solve the problem that nano calcium hydroxide cannot be used in clinical root canal treatment and other issues, to save preparation and waiting time, facilitate dispersion, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

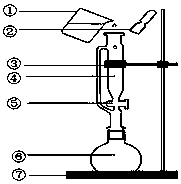

[0031] Modified CaCl with PEG400 bonding 2 : Take 150mmol / L of CaCl 2 Solution 30ml joins in the 250ml conical flask of autoclaving, then adds the PEG400 solution 10ml of 4.2mmol / L in the bottle, seals the conical flask bottleneck with aseptic tinfoil, ultrasonic cleaner vibrates 2h, and described ultrasonic frequency is 2×10 4 ~10 9 Hz, to obtain CaCl coated with inhibitor PEG400 2 solution.

Embodiment 2

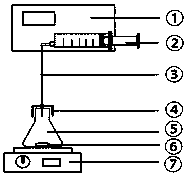

[0033] Preparation of nano-calcium hydroxide wet gel: use the digitally controlled syringe pump, sterile drug-dissolving syringe and syringe pump extension tube to form a closed aseptic reaction system, and use a 50ml sterile drug-dissolving syringe to draw 150mmol / L 50ml of NaOH, carefully installed on the digital control syringe pump, connected with the extension tube of the sterile syringe pump, and the other end of the extension tube passed through the mouth of the Erlenmeyer bottle to seal the tin foil and connected to the Erlenmeyer flask to form a closed sterile titration device (such as figure 2 shown). Turn on the power supply of the syringe pump and set the infusion rate to 20ml / L, the infusion time to 2.5h, the alarm switch after the injection is completed, and then start the infusion key to start injecting CaCl into the Erlenmeyer flask. 2 Infusion of NaOH. At the same time, stir the reaction liquid in the Erlenmeyer flask with a magnetic stirrer at a speed of 2 ...

Embodiment 3

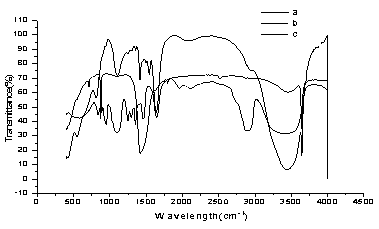

[0035] Dry the nano-calcium hydroxide wet gel and obtain dispersed nano-powder: transfer the wet gel obtained after centrifugation to a flat-bottomed Erlenmeyer flask, add 50ml of n-butanol, stir with a magnetic stirrer for 1h, and then vibrate with ultrasonic waves for 30min. The ultrasonic frequency is 2×10 4 ~10 9 Hz, heated to reflux, and the temperature was gradually raised from the azeotropic point of 366K of n-butanol and water to 399K of the boiling point of n-butanol, so that the water and n-butanol were volatilized, and the wet gel obtained was put into a vacuum dryer for suction filtration, and a white precipitate was obtained. Heat in a vacuum drying oven, and dry at a temperature of 353K for 24 hours to obtain the root canal filling material matrix nano-calcium hydroxide powder required for the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com