Non-welded power battery soft connection wire manufacturing method

A power battery and flexible connecting wire technology, applied in conductive connection, battery pack components, cable/conductor manufacturing, etc., can solve the problems of very high energy and transformer capacity requirements, large space occupation, small resistance value, etc., easy to achieve The effect of automatic operation, fast and convenient manufacturing, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

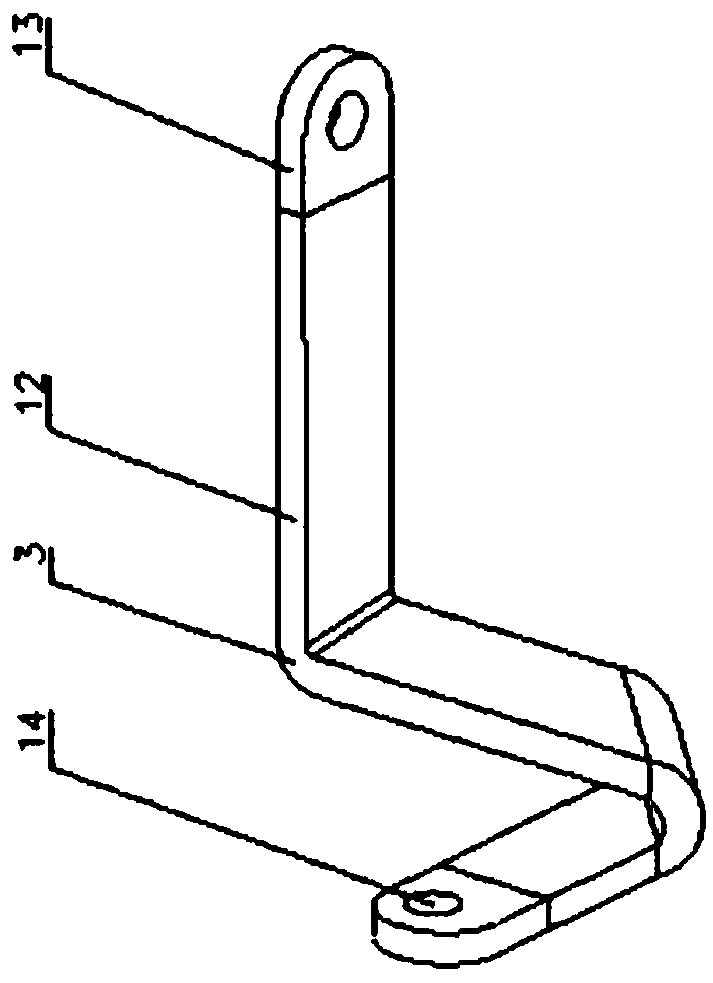

[0031] Such as figure 1 , figure 2 As shown, the power battery flexible connection wire in this embodiment includes a metal conductor 1 and a plastic insulator 2 co-extruded with the metal conductor 1, and a plurality of bending parts 3 are arranged on the metal conductor 1, and the metal conductor 1 The conductor 1 is a copper metal conductor or an aluminum metal conductor or an iron metal conductor, the thickness of the metal conductor 1 is 0.2-10 mm, and the plastic insulator 2 is a plastic insulating material or a modified rubber or a modified plastic. In this embodiment An aluminum metal conductor is used, and the metal conductor 1 includes a middle part 12 of the same profile and connecting parts 13 arranged at both ends of the middle part 12 , and connecting through holes 14 are arranged on the connecting part 13 .

Embodiment 2

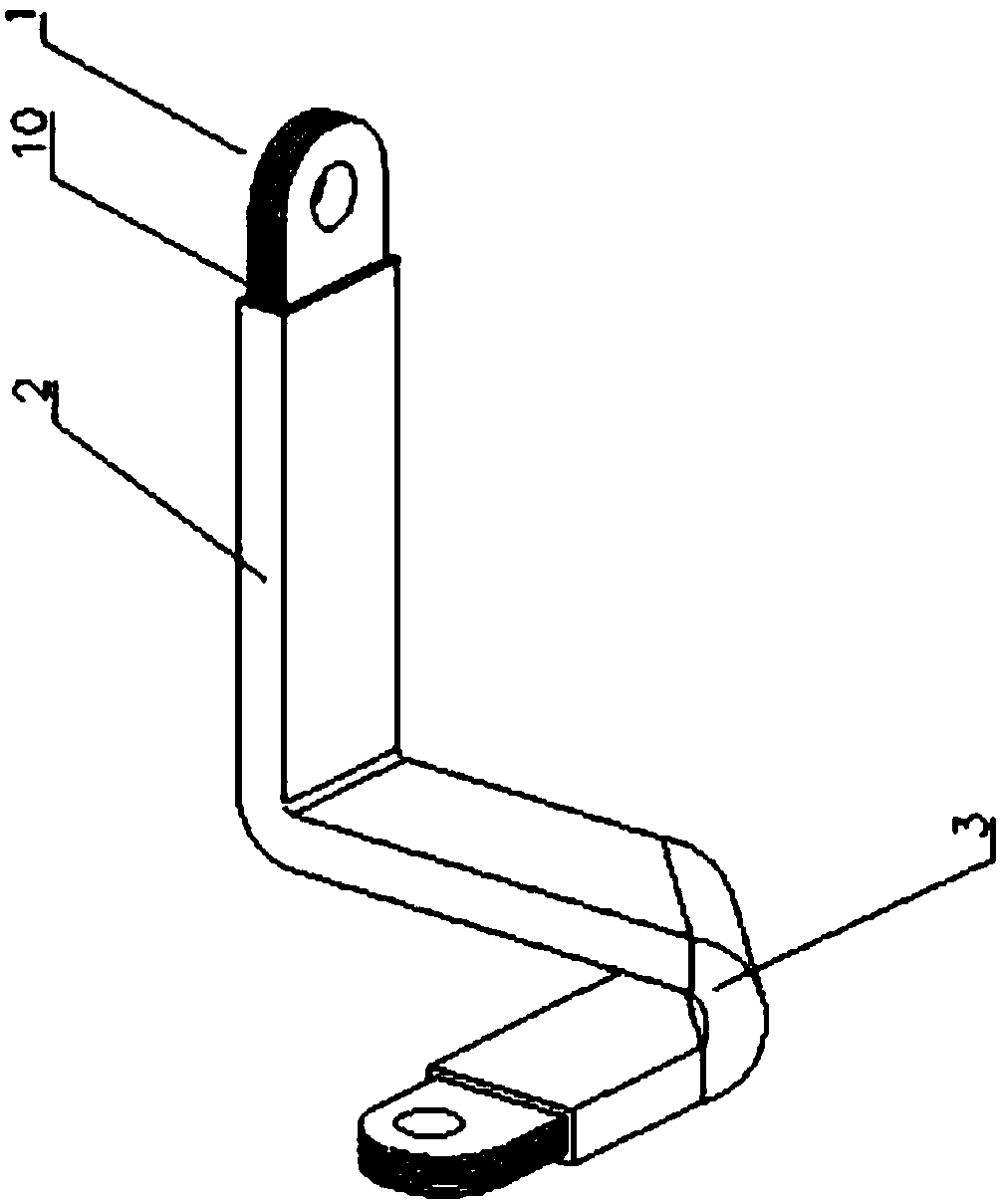

[0033] Such as image 3 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that the metal conductor 1 in this embodiment includes a multi-layer laminated metal foil 10, and the thickness of the metal foil 10 is 0.1mm-0.2mm .

Embodiment 3

[0035] This embodiment is basically the same as the second embodiment, except that the metal conductor 1 in this embodiment is a copper metal conductor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| traction force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com