High-precision simulation inter-cooling constant temperature apparatus for automobile engine testing stand

A technology of automobile engine and thermostat, which is applied in the direction of engine test, measurement device, machine/structural component test, etc., can solve the problems of increasing worthless test waiting time, increasing additional fuel consumption, unstable temperature rise, etc. Achieve improved accuracy and repeatability, good control, and small temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

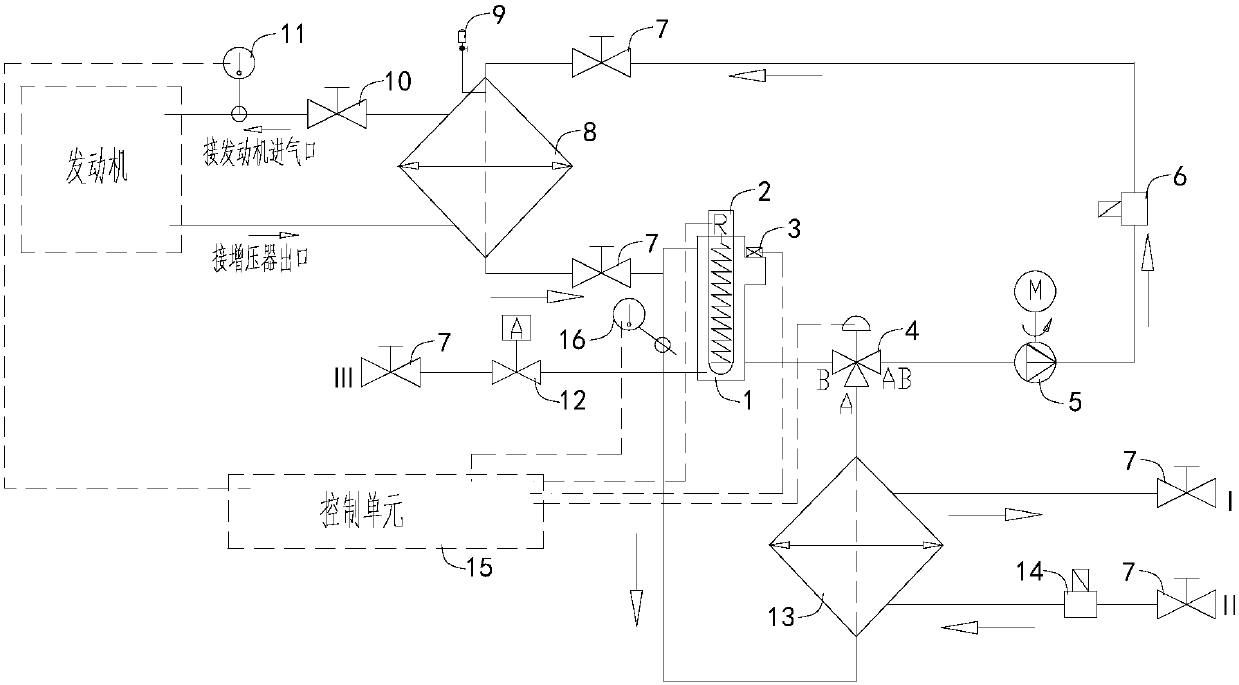

[0024] a kind of like figure 1 The automobile engine test bench uses a high-precision analog intercooler constant temperature device, which includes a water / air heat exchanger 8 that can communicate with the supercharger outlet and the air inlet of the engine and form an air circulation channel. The medium water outlet of the heater 8 is connected to the medium water inlet of the water / air heat exchanger 8 through the liquid storage tank 1, the three-way proportional regulating valve 4, the circulating water pump 5, and the flow regulating valve 6 in sequence, and the water / air heat exchange The medium water outlet of the device 8 is also connected to the other inlet of the three-way proportional regulating valve 4 through the water / water plate heat exchanger 13 through the pipeline, and the heat exchange medium inlet of the water / water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com