Variable valve lift mechanism, method for controlling valve lift and engine

A valve lift, engine technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as high engine noise, reduce noise, improve user experience, and reduce the risk of engine failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

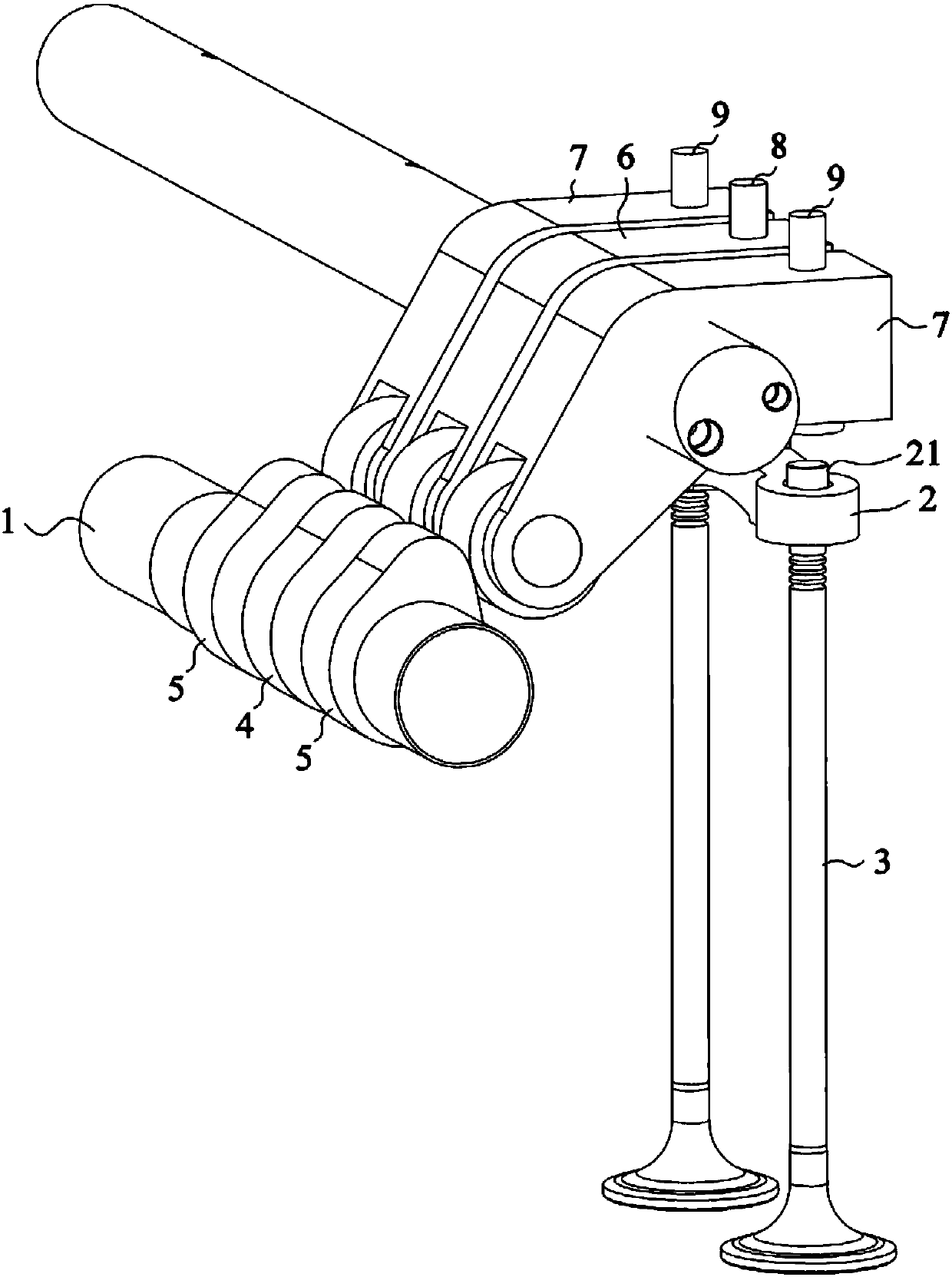

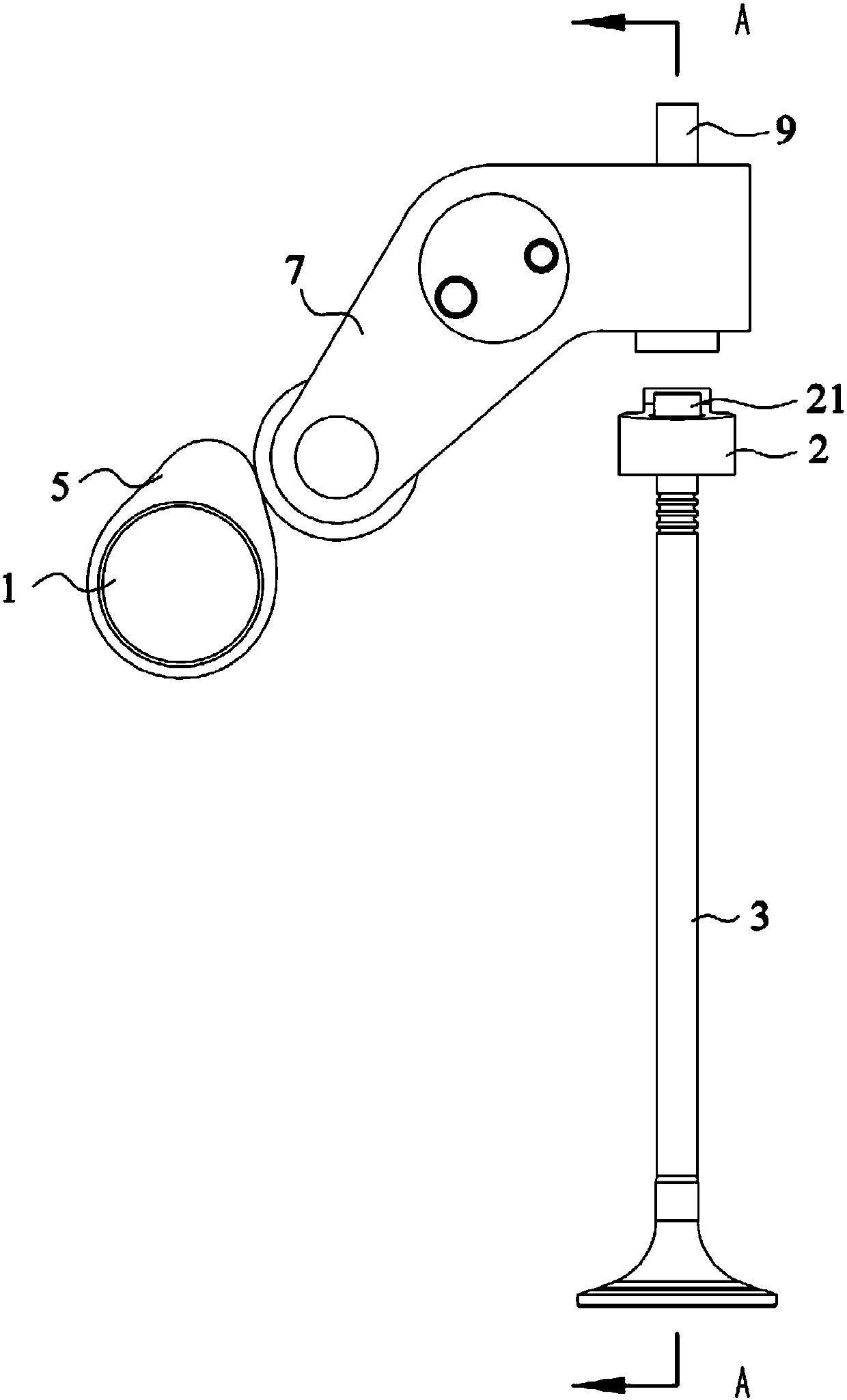

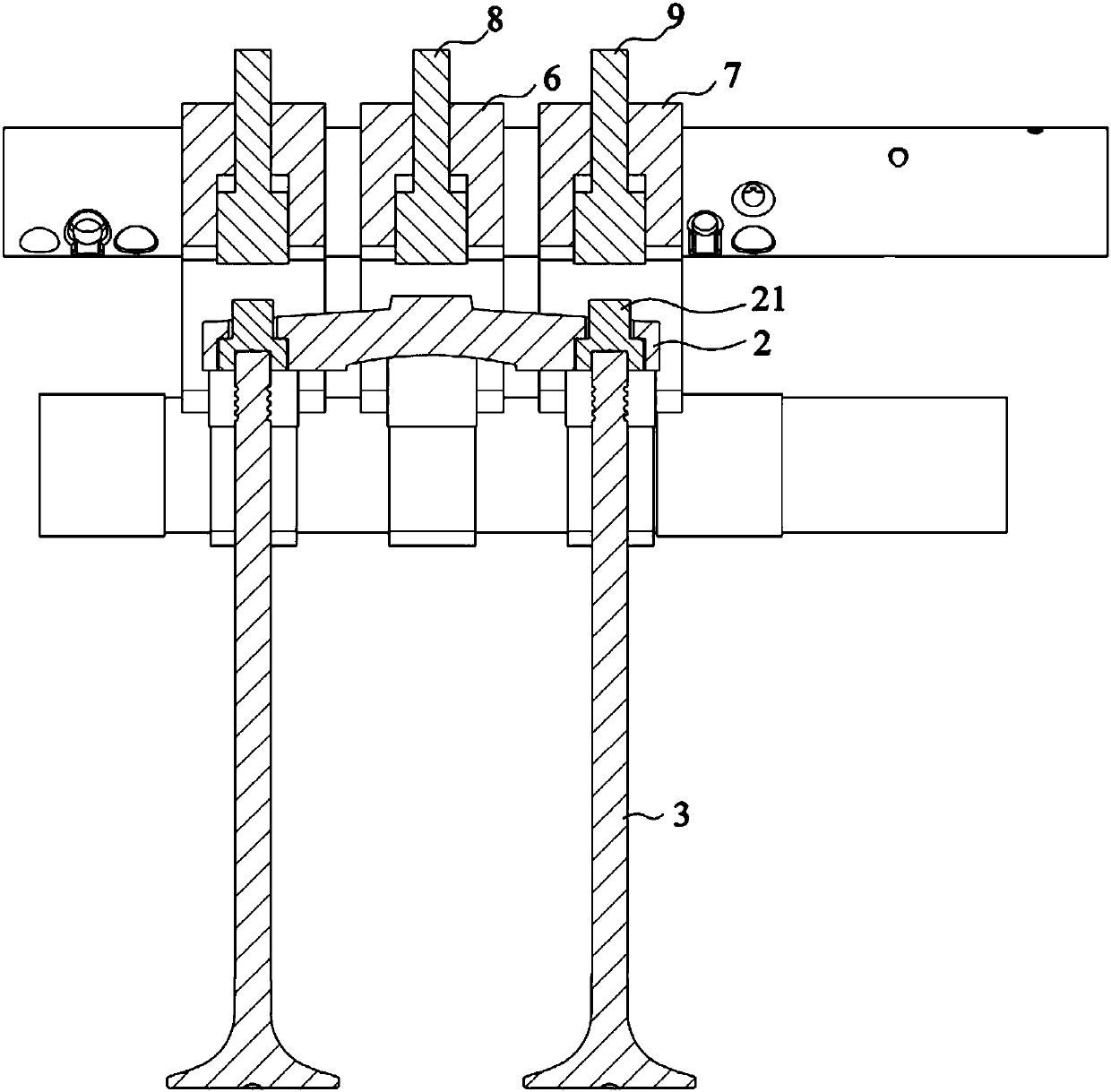

[0031] see figure 1 with figure 2 , the present embodiment provides a variable valve lift mechanism, including a camshaft 1, a valve bridge 2 and two valves 3, a valve bridge 2 is connected between the two valves 3, and both ends of the valve bridge 2 are provided with actuators pin 21.

[0032] The variable valve lift mechanism also includes a first cam 4 and a second cam 5, the two second cams 5 are located on both sides of the first cam 4, and the first cam 4 and the two second cams 5 are all arranged on the camshaft 1 and acts on one end of the first rocker arm 6 and the two second rocker arms 7 respectively, both of the first rocker arm 6 and the two second rocker arms 7 are fixed on the rocker shaft. This mechanism also comprises first piston 8 and second piston 9, and first piston 8 and two second pistons 9 are respectively arranged on the other end of first rocker arm 6 and two second rocker arms 7, and first rocker arm 6 and the other end of the second rocker arm ...

Embodiment 2

[0042] This embodiment discloses a variable valve lift mechanism and a method for controlling the valve lift. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is:

[0043] The phase angle of the first cam 4 is greater than that of the second cam 5 , that is, the first cam 4 is a high-lift cam, and the second cam 5 is a low-lift cam.

[0044] When the engine is running at low speed, the first piston 8 does not move, the first piston 8 does not contact the valve bridge 2, the two second pistons 9 are driven by hydraulic oil to elongate, and driven by the second cam 5, they abut against the two The execution pin 21, the second piston 9 can directly press on the execution pin 21, and the two execution pins 21 then press the two valves 3 to open, and the valves 3 have a low lift at this time. When the engine is running at high speed, the second piston 9 does not move and is not in contact with the actuator pin 21, the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com