Composite fertilizer for adjusting soil functions and preparation method thereof

A compound fertilizer and functional technology, applied in the field of fertilizers, can solve the problems of unsatisfactory improvement of soil functions, poor repeatability and stability, and short effective time of bacterial agents, etc., to achieve improved soil physical and chemical properties, high survival rate, enhanced The effect of soil permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

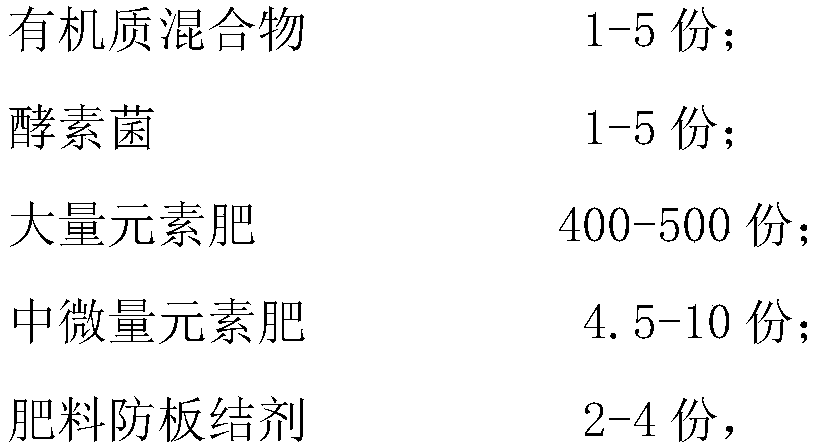

Method used

Image

Examples

preparation Embodiment 1

[0040] 1) Preparation of bio-organic fertilizer

[0041] 5kg of organic matter mixture (which contains 2.5kg of sugarcane filter mud and 2.5kg of yeast powder) and 1kg of ferment bacteria are mixed evenly, then piled up for 2 days to obtain bio-organic fertilizer;

[0042] 2) Preparation of compound fertilizer granules

[0043] Put 180kg of urea, 200kg of monoammonium phosphate, 100kg of potassium chloride, 2kg of copper sulfate, 2kg of magnesium chloride and 2kg of borax into a mixer and stir for 10 minutes. After stirring evenly, place the mixture in a drum granulator for drum granulation. Obtain compound fertilizer granules.

[0044] 3) The package of the middle isolation layer

[0045] Mix 2kg of fertilizer compaction agent evenly to obtain the material for the middle isolation layer. Then the obtained compound fertilizer granules are placed in the material bucket of the coating machine, and then the intermediate isolation layer material is put into the spray system of ...

preparation Embodiment 2

[0049] 1) Preparation of bio-organic fertilizer

[0050] 5kg of organic matter mixture (which contains 2.5kg of sugarcane filter mud and 2.5kg of yeast powder) and 3kg of ferment bacteria are mixed evenly, and then piled up for 1 day to obtain bio-organic fertilizer;

[0051] 2) Preparation of compound fertilizer granules

[0052] Put 200kg of urea, 200kg of monoammonium phosphate, 100kg of potassium chloride, 1kg of copper sulfate, 1kg of magnesium chloride, 1kg of ferrous sulfate, 1kg of zinc sulfate, 0.5kg of ammonium molybdate and 1kg of borax in a mixer and stir for 10 minutes. , the mixture is placed in a drum granulator for drum granulation to obtain compound fertilizer granules.

[0053] 3) The package of the middle isolation layer

[0054] Mix 2kg of fertilizer compaction agent evenly to obtain the material for the middle isolation layer. Then the obtained compound fertilizer granules are placed in the material bucket of the coating machine, and then the intermedia...

preparation Embodiment 3

[0058] 1) Preparation of bio-organic fertilizer

[0059] 10kg of organic matter mixture (which contains 5kg of sugarcane filter mud and 5kg of yeast powder) and 3kg of enzyme bacteria are mixed evenly, and then stacked for 3 days to obtain bio-organic fertilizer;

[0060] 2) Preparation of compound fertilizer granules

[0061] Put 220kg urea, 300kg monoammonium phosphate, 300kg potassium chloride, 10kg copper sulfate, 10kg magnesium chloride, 10kg ferrous sulfate, 10kg zinc sulfate, 5kg ammonium molybdate and 10kg borax into the mixer and stir for 10 minutes. After stirring evenly, The mixture is placed in a drum granulator for drum granulation to obtain compound fertilizer granules.

[0062] 3) The package of the middle isolation layer

[0063] Mix 4kg of fertilizer compaction agent evenly to obtain the material for the middle isolation layer. Then the obtained compound fertilizer granules are placed in the material bucket of the coating machine, and then the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com