microRNA nanometer microcapsule-bone meal composite material and preparation method thereof

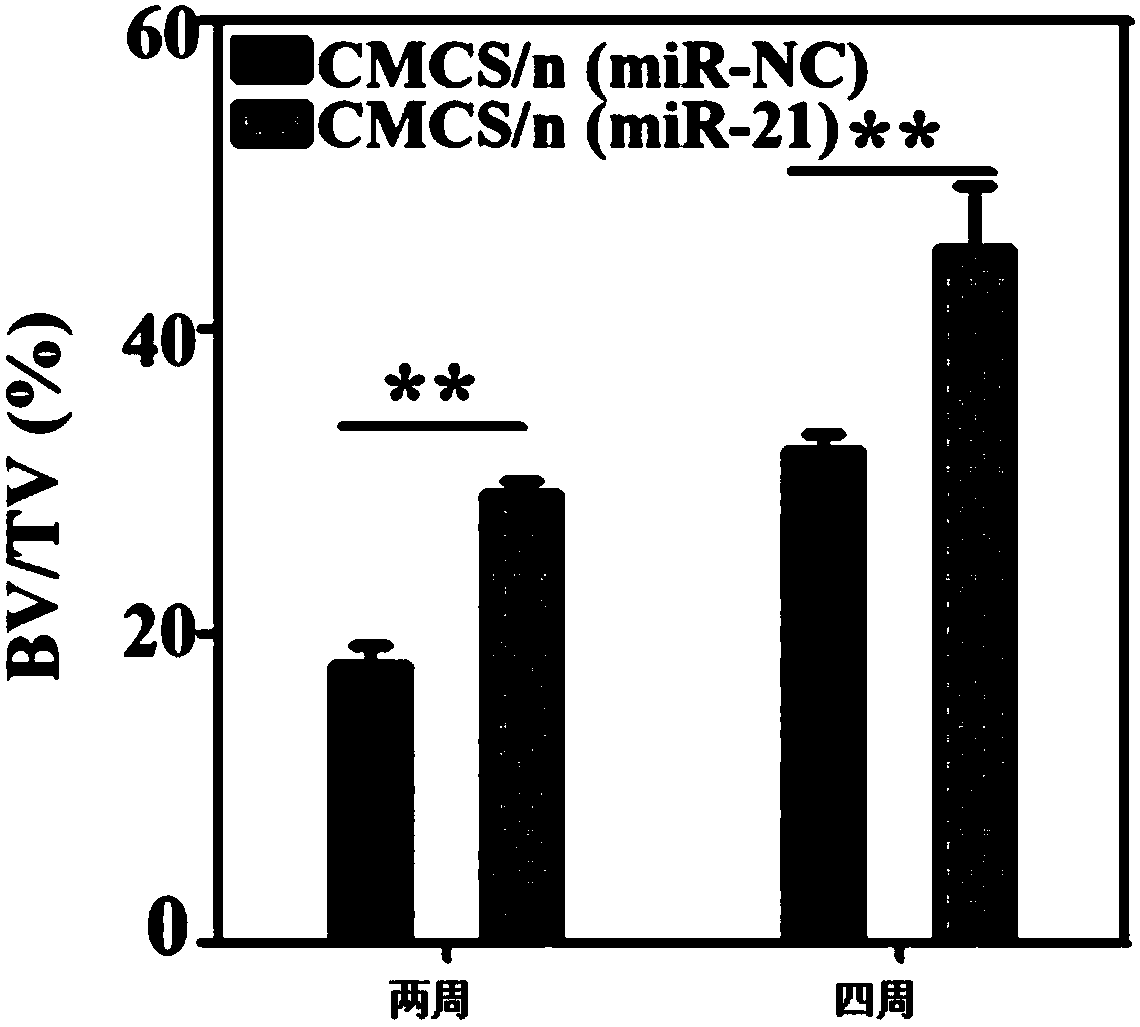

A technology of nano-microcapsules and composite materials, applied in the field of biomedical tissue engineering materials, can solve the problems of lack, lack of osteogenesis and osteoinductivity, etc., improve the quality of osteogenesis, and solve the problem of bone powder without osteogenesis and osteoinduction Sexuality and the effect of shortening the bone formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

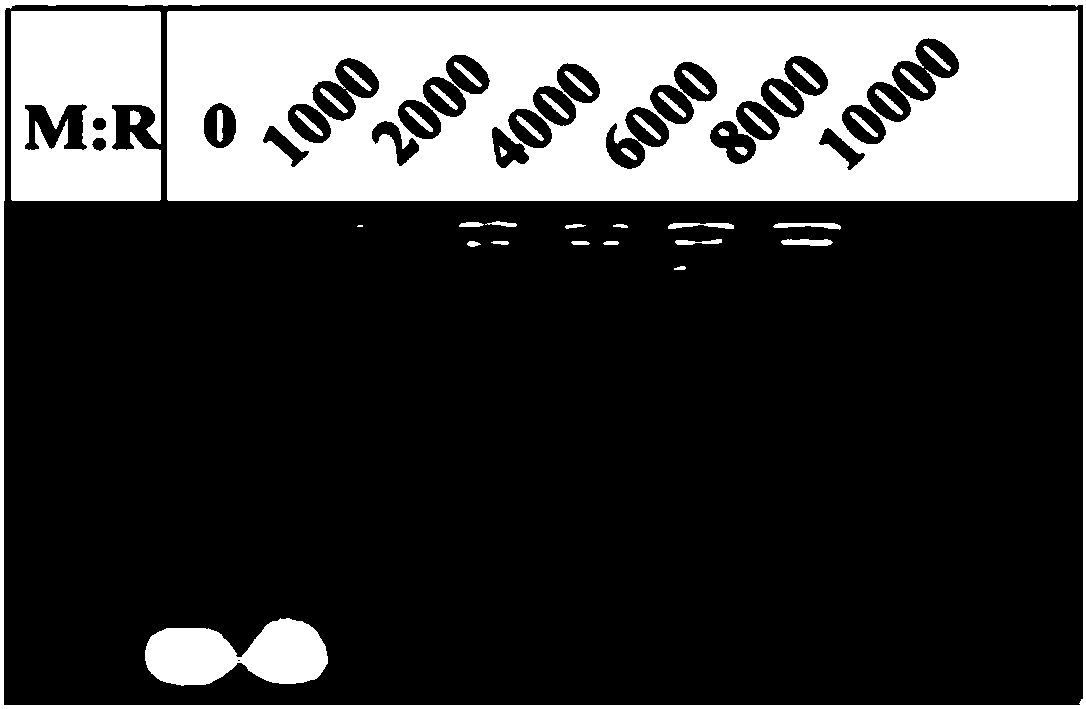

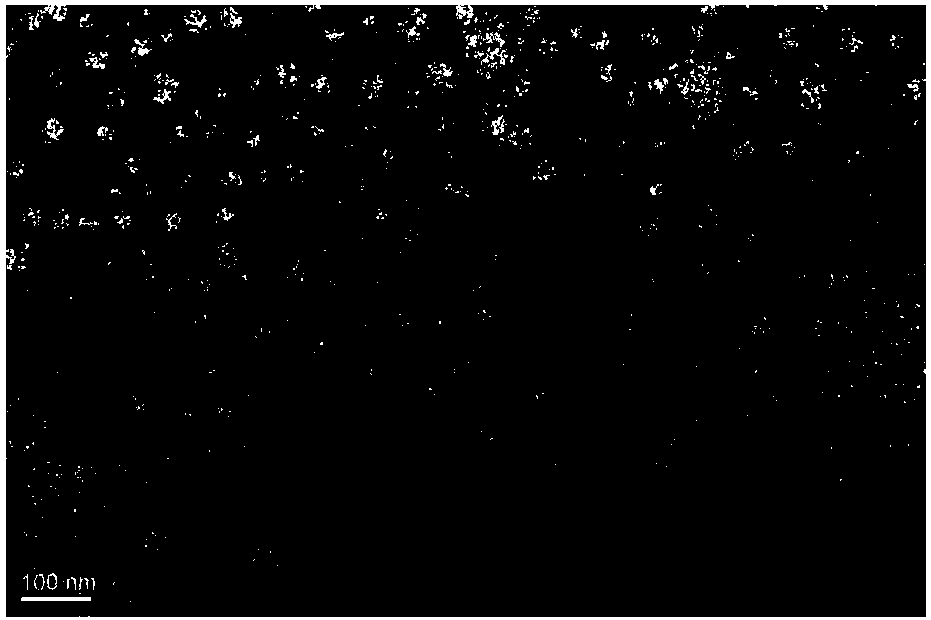

[0054] Example 1—preparation of MicroRNA nanocapsules, MicroRNA selects microRNA-21

[0055] Dissolve microRNA-21 at a concentration of 20 μM in 10 μl of RNase-depleted water. Add monomers N-(3-aminopropyl)methacrylamide and acrylamide to deoxygenated RNase-free double-distilled water, and control the molar ratio of the monomer to microRNA-21 to be (the ratio of the amount of substances) 2000: 1. Add the crosslinking agent ethylene glycol dimethacrylate according to the molar ratio of N-(3-aminopropyl)methacrylamide, acrylamide and ethylene glycol dimethacrylate in a ratio of 1:1:1 , put the microRNA-21 solution in a 200 μL microcentrifuge tube and use magnetic stirring to mix evenly. Under the condition of continuous stirring and dispersion (150-200 revolutions per minute), the positively charged monomers are separated by electrostatic interaction and hydrogen bond interaction. , neutral monomers and cross-linkers are enriched around the microRNA-21 molecule. Then add initi...

Embodiment 2

[0060] Example 2—Preparation of MicroRNA nanocapsules-bone meal composite material

[0061] Select the MicroRNA nano-microcapsule solution (dispersion system) prepared in Example 1 and the Bio-oss bone powder with a diameter of 1mm, mix the Bio-oss bone powder and microRNA-21 nano-microcapsule solution at a volume ratio of 50:1, and soak for 2h Take it out for later use.

Embodiment 3

[0062] Embodiment 3—preparation of MicroRNA nano-microcapsules-chitosan composite material

[0063] 300mg carboxymethyl chitosan (carboxymethyl degree 80%, number average molecular weight 40000) powder is added 1mL above-mentioned concentration and is in the microRNA-21 nanometer microcapsule solution of 5 μ M (the MicroRNA nanometer microcapsule solution prepared in embodiment 1 (dispersion System)), shaking and stirring until the carboxymethyl chitosan is completely dissolved. The obtained mixture was sucked into a syringe, placed in an ice cube for 30 min, then taken out, and placed at 4°C to obtain an injectable microRNA-activated hydrogel material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com