Automatic liquid changer for water culturing

An automatic and hydroponic technology, applied in the fields of cultivation, application, soilless cultivation, etc., can solve the problems of inaccurate quantity, time-consuming, slow liquid changing speed, etc., to reduce waste, reduce labor expenditure, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

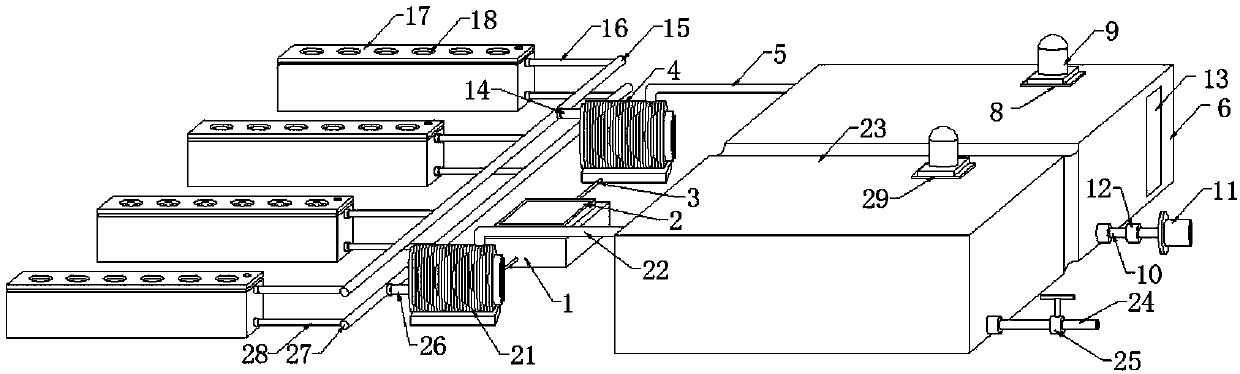

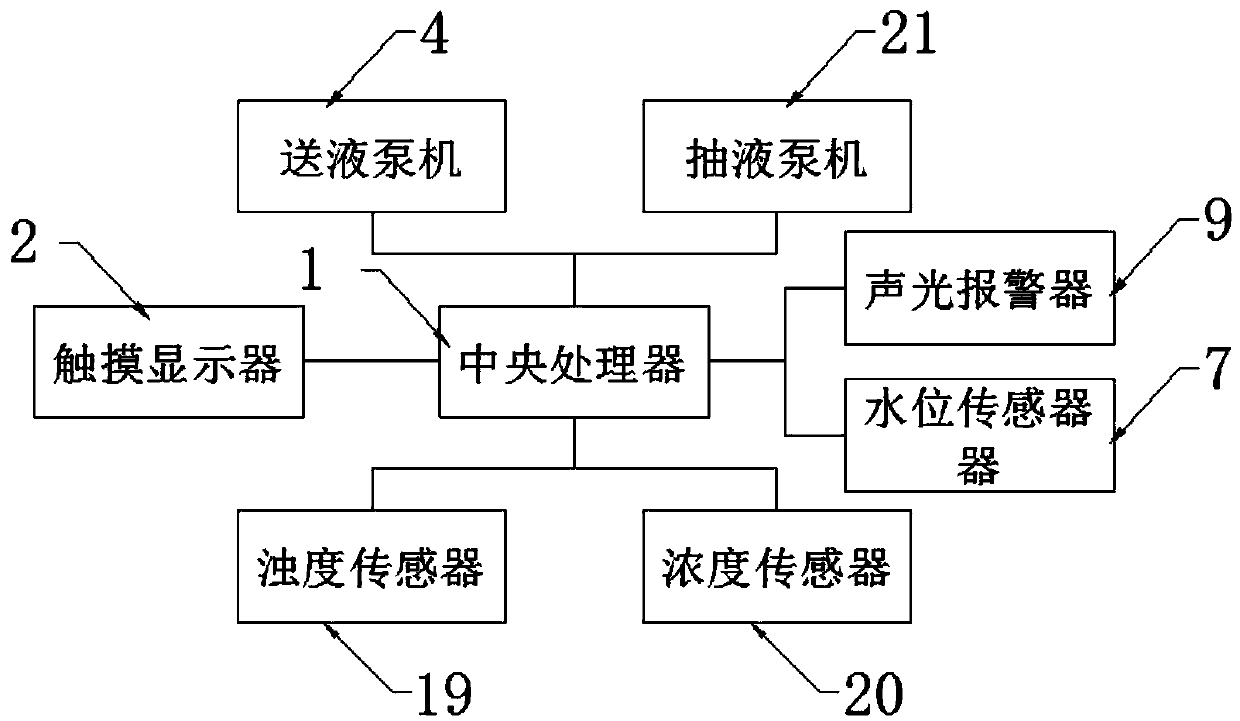

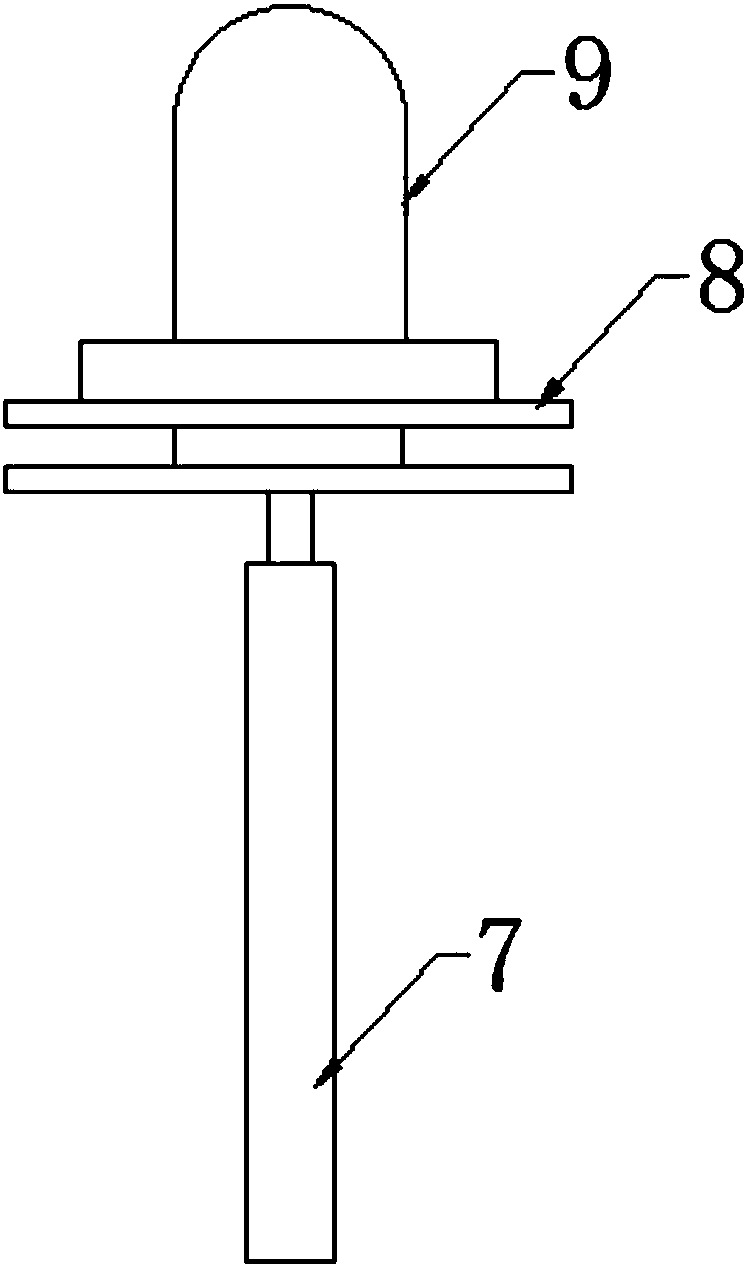

[0022] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: an automatic liquid changing device for hydroponics, including a central processing unit 1, characterized in that: the upper side of the central processing unit 1 is provided with a touch display 2, and the central processing unit The device 1 is respectively connected with a liquid delivery pump 4 and a liquid suction pump 21 through a wire 3, and the liquid delivery pump 4 is connected with a nutrient solution tank 6 through a liquid suction pipe 5, and a water level sensor is arranged in the nutrient solution tank 6 7. The water level sensor 7 is connected to the upper side panel of the nutrient solution tank 6 through the No. 1 I-shaped fixing plate 8, and the upper end of the No. 1 I-shaped fixing plate 8 is connected with an audible and visual alarm 9, and the nutrient solution tank 6 One side is connected with a liquid-feeding pipe 10, and the other end of the liquid-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com