A kind of LED encapsulation method

A LED package, hemispherical technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of insufficient contact between the bottom surface of the heat sink, affecting the heat dissipation effect, and reducing the light intensity, so as to suppress the total reflection effect and improve heat convection speed, improving the effect of luminous dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

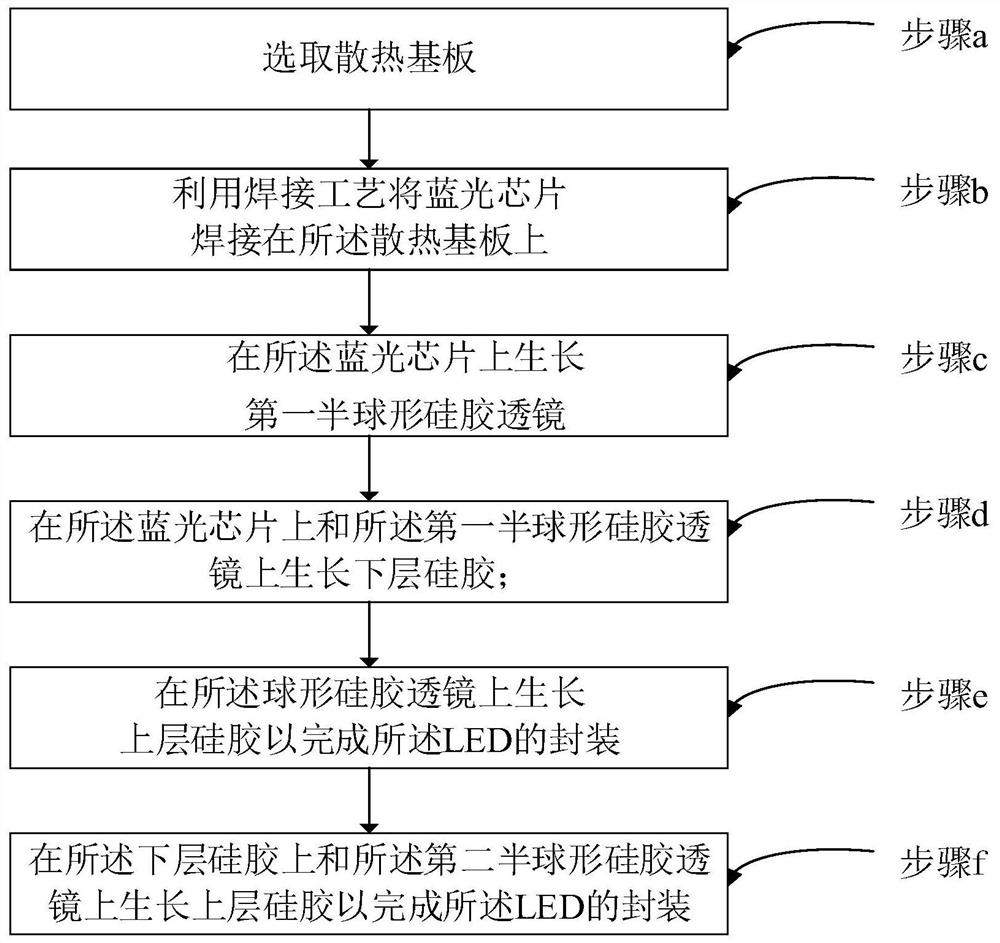

[0054] See figure 1 , figure 1 It is a flow chart of an LED packaging method provided by an embodiment of the present invention. The method comprises the steps of:

[0055]Step a, selecting a heat dissipation substrate;

[0056] Step b, using a welding process to weld the blue light chip on the heat dissipation substrate;

[0057] Step c, growing a first hemispherical silica gel lens on the blue chip;

[0058] Step d, growing a lower layer of silica gel on the blue light chip and the first hemispherical silica gel lens;

[0059] Step e, growing a second hemispherical silica gel lens on the lower layer of silica gel;

[0060] Step f, growing an upper layer of silica gel on the lower layer of silica gel and the second hemispherical silica gel lens to complete the packaging of the LED.

[0061] Preferably, the heat dissipation substrate is made of iron and has a thickness of 0.5-10mm.

[0062] Preferably, a circular through hole is provided in the heat dissipation substrat...

Embodiment 2

[0091] See figure 2 , figure 2 It is a schematic flow chart of an LED packaging method provided by an embodiment of the present invention. On the basis of the above embodiments, this embodiment will introduce the process flow of the present invention in more detail. The method includes:

[0092] S1, preparation of heat dissipation substrate;

[0093] S11, preparation of support / radiation substrate;

[0094] Specifically, select a heat dissipation substrate 101 with a thickness of 0.5-10 mm and a material of iron, and cut the heat dissipation substrate 101;

[0095] S12. Cleaning of the support / heat dissipation substrate;

[0096] Specifically, clean the stains on the heat dissipation substrate 101 and the support, especially the oil stains;

[0097] S13, baking of the bracket / radiation substrate;

[0098] Specifically, the cleaned heat dissipation substrate 101 and the support are baked to keep the heat dissipation substrate 101 and the support dry.

[0099] Preferab...

Embodiment 3

[0136] Please also see image 3 , Figure 4 , Figure 5 and Figure 6a ~ Figure 6b , image 3 A schematic cross-sectional view of an LED package structure provided by an embodiment of the present invention, Figure 4 A schematic cross-sectional view of a heat dissipation substrate provided by an embodiment of the present invention, Figure 5 A schematic cross-sectional view of a Blu-ray chip provided by an embodiment of the present invention, Figure 6a A schematic cross-sectional view of a hemispherical silicone lens provided in an embodiment of the present invention, Figure 6b A cross-sectional schematic diagram of another hemispherical silicone lens provided by an embodiment of the present invention. On the basis of the above embodiments, this embodiment will introduce the LED packaging structure of the present invention, and the LED packaging structure includes:

[0137] heat dissipation substrate 101;

[0138] Among them, such as Figure 4 As shown, the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com