Photo-biodegradable and antibacterial plastic and preparation method thereof

A dual-degradation and plastic technology, which is applied in the field of plastic preparation, can solve the problems of degradable plastics without antibacterial properties, slow degradation speed of degradable plastics, general degradation effect, etc., to achieve accelerated degradation speed, improved degradable performance, and no secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

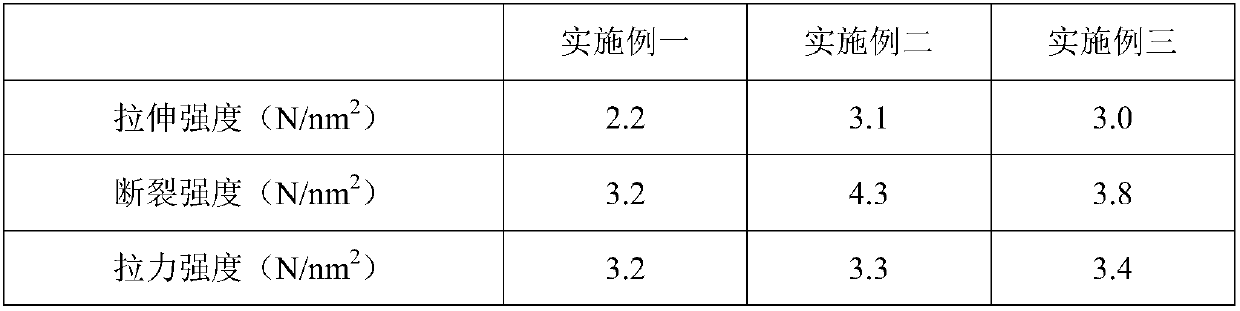

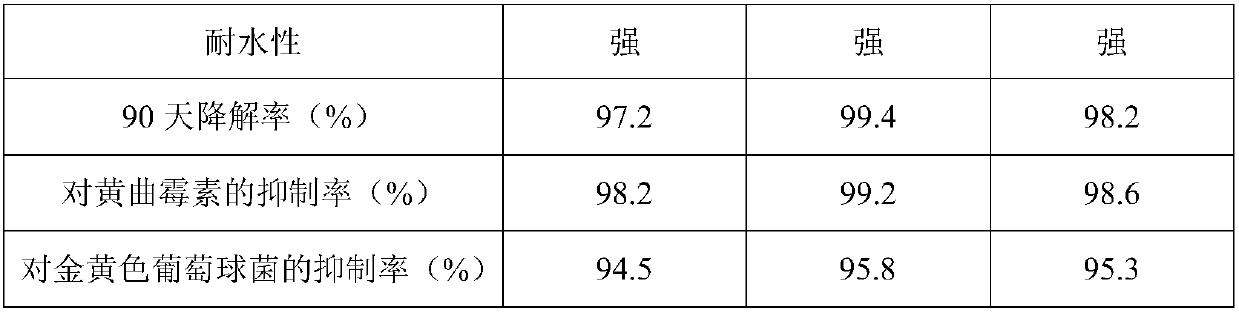

Examples

Embodiment 1

[0022] Weigh the raw materials in the following weight ratio: 20 parts of polyethylene, 15 parts of calcium carbonate, 15 parts of modified starch, 5 parts of maltodextrin, 5 parts of wood fiber, 1 part of gelatin, 1 part of glycerin, diphenylcyclopropenone 2 parts, 1 part of iron disulfide carbamate, 1 part of nano-titanium dioxide, 8 parts of polyhydroxyalkanoate, 1 part of sodium diacetate, 1 part of sodium lignosulfonate, 2 parts of acetyl tributyl citrate, oxidized polyethylene 2 parts of wax.

[0023] Prepare as follows:

[0024] (1) Add polyethylene, modified starch, maltodextrin, and wood fiber into ethanol, stir at a temperature of 50°C and a pH of 8 to obtain a paste mixture, add the paste mixture to the reaction kettle, and Reaction for 20min at 2MPa;

[0025] (2) dissolving gelatin in glycerin at a temperature of 40° C., and then mixing it with the mixed solution obtained in step (1);

[0026] (3) Mix polyhydroxyalkanoate, sodium diacetate, sodium lignin sulfona...

Embodiment 2

[0030] Weigh the raw materials in the following weight ratio: 25 parts of polyethylene, 20 parts of calcium carbonate, 20 parts of modified starch, 10 parts of maltodextrin, 10 parts of wood fiber, 5 parts of gelatin, 3 parts of glycerin, diphenylcyclopropenone 6 parts, 4 parts of iron disulfide carbamate, 3 parts of nano-titanium dioxide, 12 parts of polyhydroxyalkanoate, 2 parts of sodium diacetate, 3 parts of sodium lignosulfonate, 7 parts of acetyl tributyl citrate, oxidized polyethylene 6 parts of wax.

[0031] Prepare as follows:

[0032] (1) Add polyethylene, modified starch, maltodextrin, and wood fiber into ethanol, stir at a temperature of 70°C and a pH of 9 to obtain a paste mixture, add the paste mixture to the reaction kettle, and Reaction for 25min at 3MPa;

[0033] (2) dissolving gelatin in glycerin at a temperature of 60° C., and then mixing it with the mixed solution obtained in step (1);

[0034] (3) Mix polyhydroxyalkanoate, sodium diacetate, sodium ligni...

Embodiment 3

[0038] Weigh the raw materials in the following weight ratio: 30 parts of polyethylene, 25 parts of calcium carbonate, 25 parts of modified starch, 15 parts of maltodextrin, 15 parts of wood fiber, 10 parts of gelatin, 5 parts of glycerin, diphenylcyclopropenone 10 parts, 7 parts of iron disulfide carbamate, 5 parts of nano-titanium dioxide, 16 parts of polyhydroxyalkanoate, 3 parts of sodium diacetate, 5 parts of sodium lignosulfonate, 12 parts of acetyl tributyl citrate, oxidized polyethylene 10 parts of wax.

[0039] Prepare as follows:

[0040](1) Add polyethylene, modified starch, maltodextrin, and wood fiber into ethanol, and stir under the condition that the temperature is 80°C and the pH is 10 to obtain a paste mixture, which is added to the reaction kettle, and Reaction for 30min at 4MPa;

[0041] (2) dissolving gelatin in glycerin at a temperature of 80° C., and then mixing it with the mixture obtained in step (1);

[0042] (3) Polyhydroxyalkanoate, sodium diaceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com