Self-repairing repeatable-processed polysiloxane elastomer, preparation method and application

A technology of repeated processing and polysiloxane, which is applied in the field of new materials, can solve the problems of high reprocessing temperature, poor mechanical properties, mechanical properties and self-repairing properties can not be improved at the same time, to improve mechanical strength and simple synthesis process easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

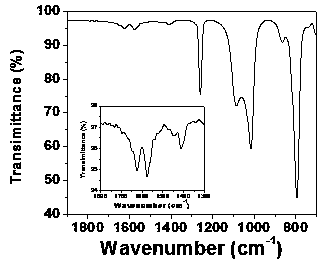

[0025] A self-healing and reproducible polysiloxane elastomer with the following general structural formula:

[0026]

[0027] Among them, R and R1 are long chains composed of carbon, hydrogen, oxygen, and nitrogen.

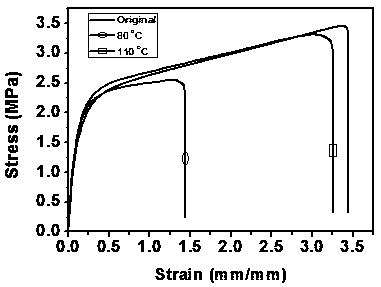

[0028] A preparation method of a self-healing and reproducible polysiloxane elastomer, comprising the following steps: 3-13 parts by weight of crosslinking agent, 79 parts by weight of amino-terminated polydimethylsiloxane, 8~ 18 parts by weight of diisocyanate and 1 to 5 parts by weight of metal ion catalyst were dissolved in tetrahydrofuran to obtain a mixed solution. The concentration of the mixed solution was controlled to be 0.1 to 0.6 g / mL, and the reaction was stirred at room temperature for 5 minutes; then the prepolymer was poured Put it into a polytetrafluoroethylene mold and cure at room temperature for 24 hours, then put it in an oven at 80° C. to continue curing for 4 hours, and then take it out of the mold to obtain a self-healing and repeatable polysilo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com