Tough stretchable compressible polymer/graphene oxide nano composite hydrogel with excellent self-repairing performance

A nanocomposite and hydrogel technology, applied in the field of self-healing hydrogel, can solve the problems of low self-healing efficiency, achieve excellent mechanical properties, enhance self-healing ability and mechanical strength, and achieve high self-healing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

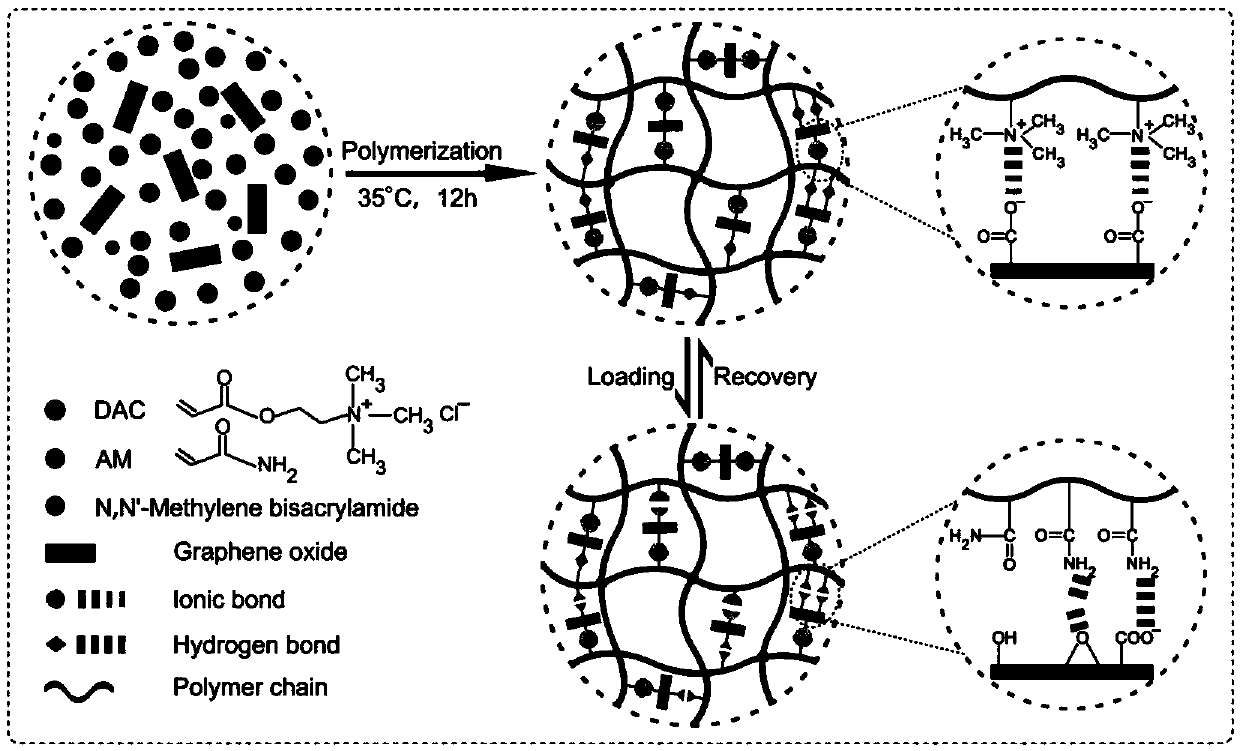

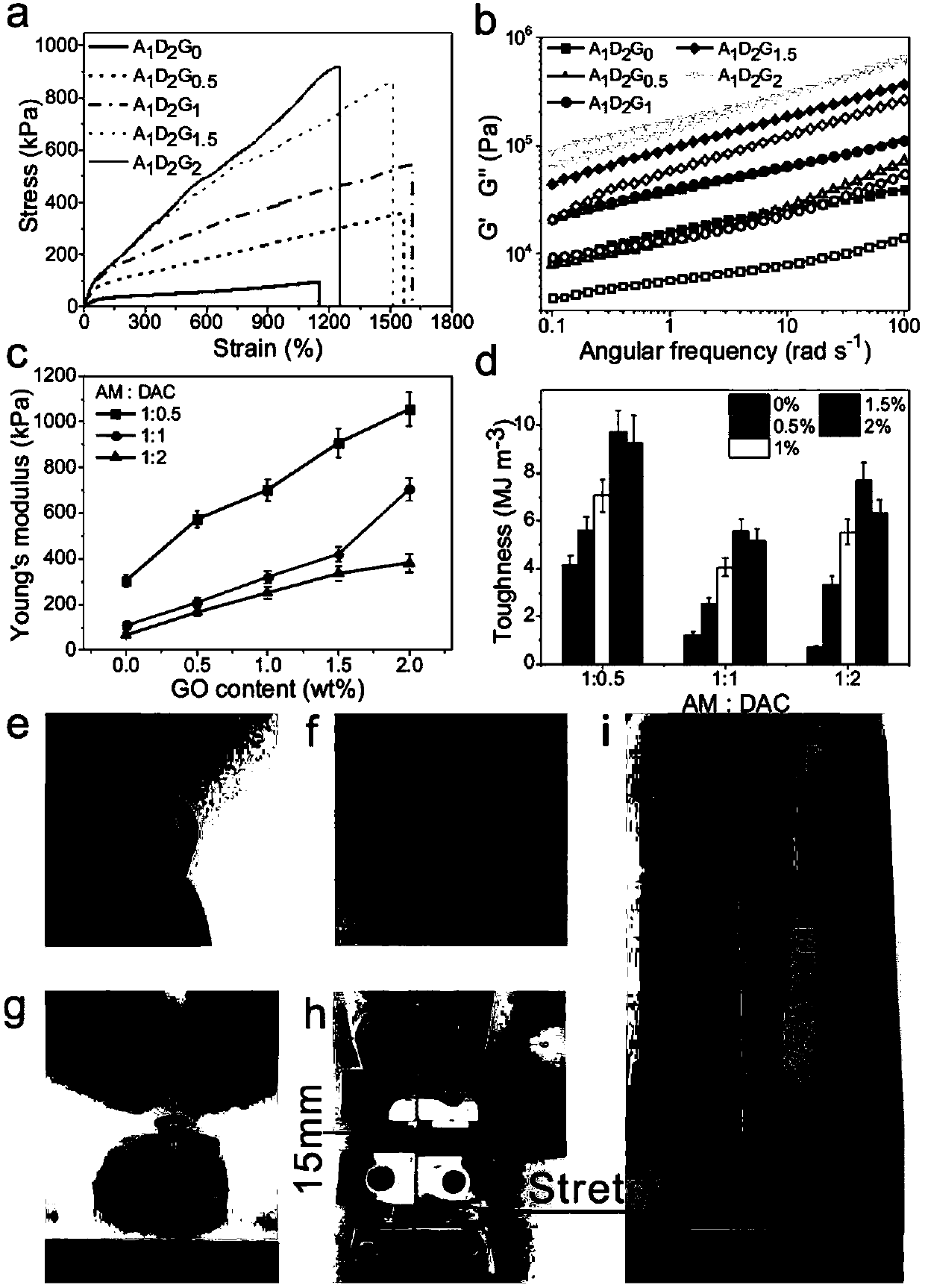

Method used

Image

Examples

Embodiment 1

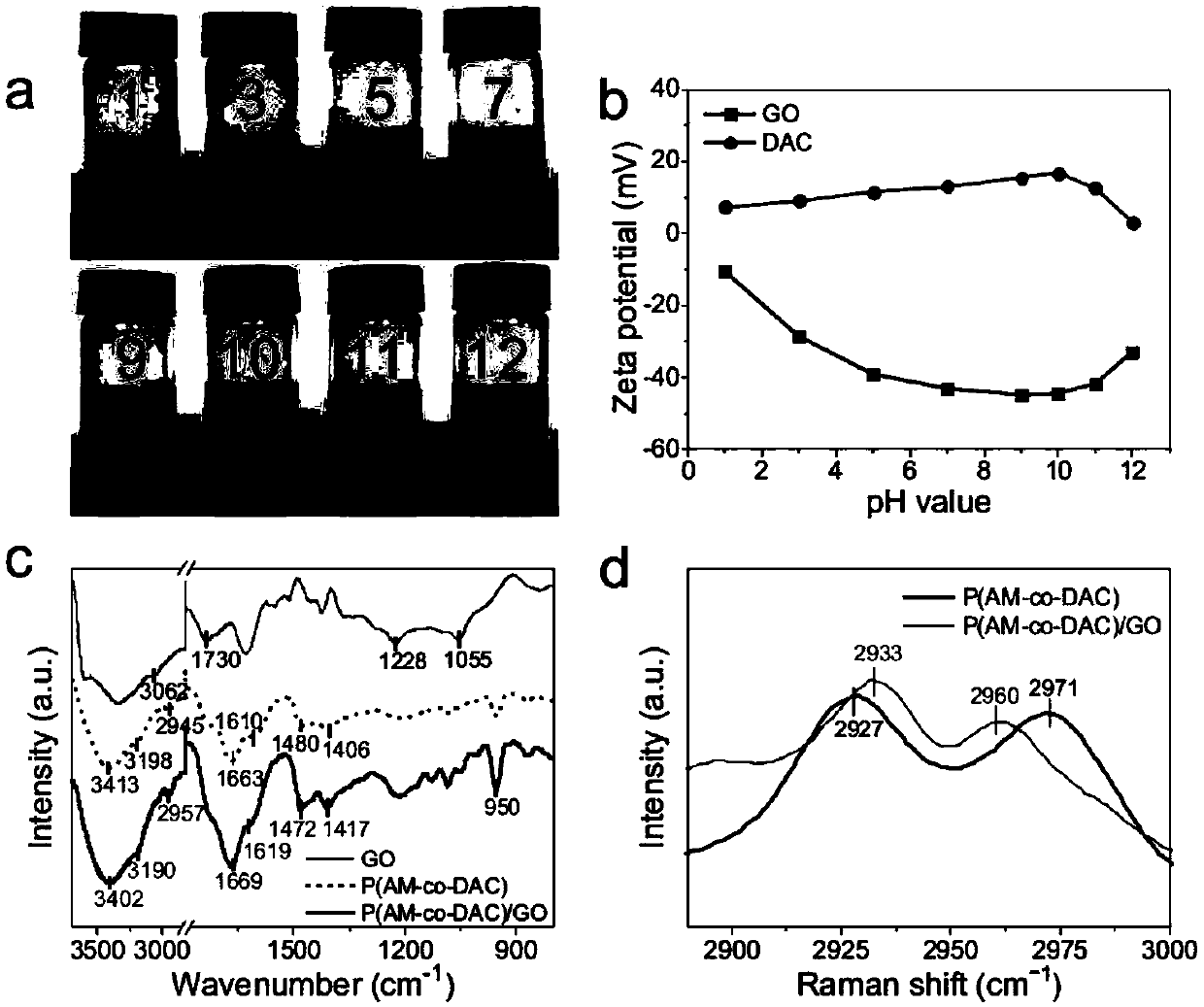

[0046] 1 Experimental part

[0047] 1.1 Experimental reagents and materials

[0048] Graphite powder (8000 mesh, purity 99.95%), sodium formaldehyde sulfoxylate hydrate (ALD), N,N'-methylenebisacrylamide (MBA), acrylamide (AM) and 2,2'-azobis (2-Methylpropionamidine) dihydrochloride (AIBA) was supplied by Aladdin Corporation. Ammonium persulfate (APS), concentrated sulfuric acid (95–98%), concentrated hydrochloric acid (36–38%), ammonia water, potassium permanganate, all of analytical grade (purchased from Beijing Chemical Company (China)). Hydrogen peroxide (H 2 o 2 ) and sodium nitrate were purchased from Laiyang Kangde Chemical Company. Acryloyloxyethyltrimethylammonium chloride, 80wt% aqueous solution (DAC) is purchased from Bailingwei Company

[0049] 1.2 Preparation of graphene oxide

[0050] Graphene oxide was prepared from natural graphite by the Hummers method. Briefly, 36ml of sulfuric acid was added to a 250ml round bottom flask placed in an ice bath. About ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com