Multilayer waterproof roll for composite internal-enhancing fabric and production process thereof

A technology for reinforcing fabrics and waterproof membranes, which is applied in the field of building materials. It can solve the problems of weak composite strength of composite waterproof membranes, increase the production process and cost of products, and poor composite strength between layers, so as to achieve overall flatness, not easy to shrink, and save equipment. Investment and maintenance costs, the effect of improving the force bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (coil)

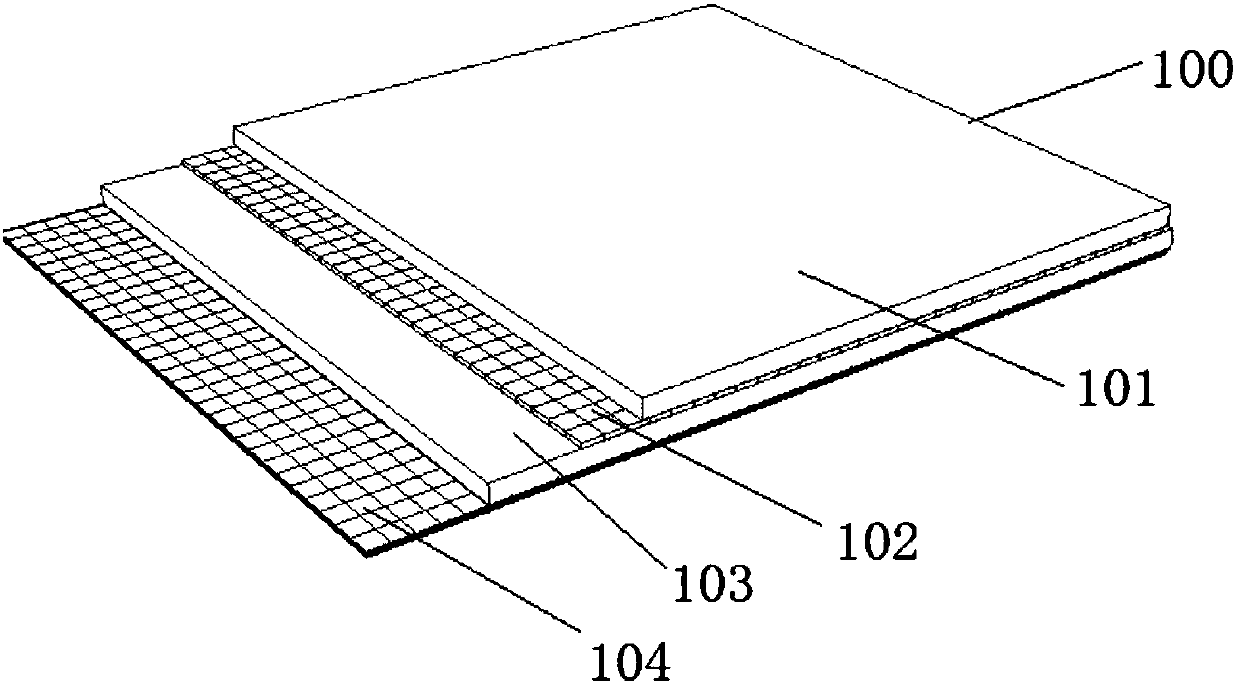

[0032] Such as figure 1 As shown, this embodiment provides a multi-layer waterproof membrane 100 of composite internal reinforcement fabric, including a surface layer 101 , an internal reinforcement fabric layer 102 , a back layer 103 , and a backing layer 104 bonded sequentially from top to bottom. Both the surface layer 101 and the back layer 103 are main material layers, and the main material can be a polymer material, generally commonly used resins, such as thermoplastic resins such as chlorinated polyethylene and polyvinyl chloride.

[0033] Wherein, the inner reinforcing fabric layer 102 is polyester grid cloth.

[0034] Wherein, the backing layer 104 is polyester fiber cloth.

[0035]During use, the multi-layer waterproof membrane of the composite inner reinforcement fabric mainly relies on the inner reinforcement grid cloth to provide strength, while the backing layer 104 provides applicability, so the multi-layer waterproof membrane 100 ...

Embodiment 2

[0038] Embodiment 2 (coil laying method)

[0039] According to the multi-layer waterproof membrane 100 of a composite internal reinforcement fabric provided in Example 1, when laying the multi-layer waterproof membrane 100 in this embodiment, it can be laid with reference to the construction method of the backing type waterproof membrane: The waterproof membrane of the backing is laid according to the construction method of full adhesion, which has the characteristics of fast construction, safety and firm bonding. The concrete laying steps of described multi-layer waterproof coiled material 100 are as follows:

[0040] (1) Clean the surface of the base layer before construction, ensure the surface is clean, and confirm that the surface of the base layer is smooth and free of oil and other pollution;

[0041] (2) When applying the adhesive, the elastic line should be measured, and the adhesive should be applied according to the reference line, and the application should be eve...

Embodiment 3

[0048] Embodiment 3 (production technology)

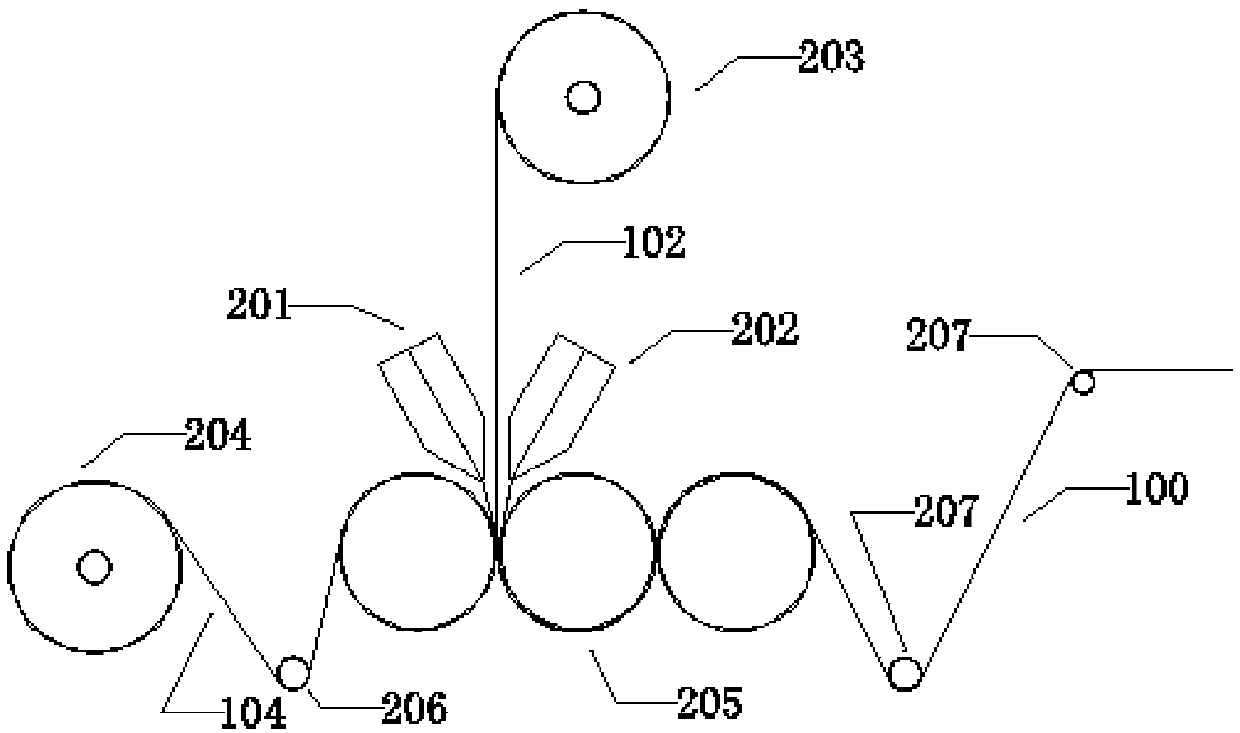

[0049] refer to figure 2 , the multi-layer waterproof membrane production process of the composite internal reinforcement fabric provided by the invention is as follows:

[0050] (1) Form the back layer 103 and the surface layer 101 of the product respectively by the first forming die 201 and the second forming die 202, and the product back layer 103 and the face layer 101 can adopt resin materials;

[0051] (2) Composite inner reinforcement fabric layer 102 (can adopt fiber material, such as: polyester grid cloth) is put into from the middle of two described molding molds through the first unwinding device 203 above the molding mold to form the middle layer, Under the traction force of the three-roll calender 205, the back layer 103, the surface layer 101 and the put-in middle layer formed from the molding die are pressed between the two rolls of the three-roll calender 205;

[0052] (3) backing layer 104 adopts fiber material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com