Method for producing grid gauze having opened holes

A technology of opening holes and manufacturing methods, which is applied to chemical instruments and methods, perforated fabrics, textiles, and papermaking, and can solve problems such as poor adhesion of the loop layer, easy adhesion of the loop layer to glue, and emery adhesion. Achieve the effects of improving the grinding effect and service life, good chip removal effect, and large grid distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable your review committee to have a further understanding and recognition of the features and characteristics of the present invention, the following preferred embodiments are listed below and described as follows with the help of drawings:

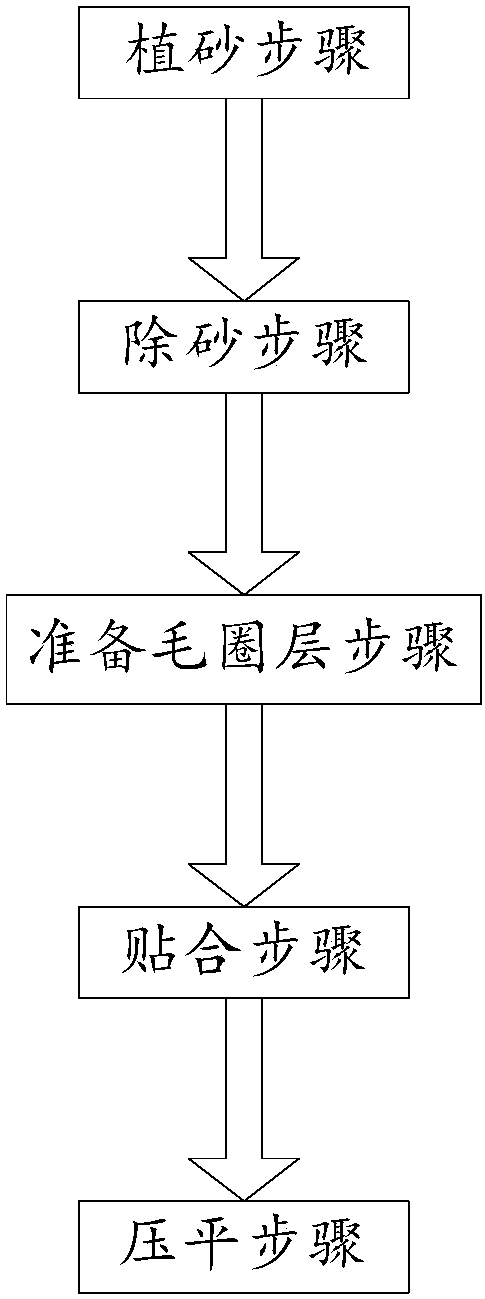

[0036] see Figure 1 to Figure 7 , a kind of mesh gauze manufacture method with open hole of the present invention mainly comprises the following steps:

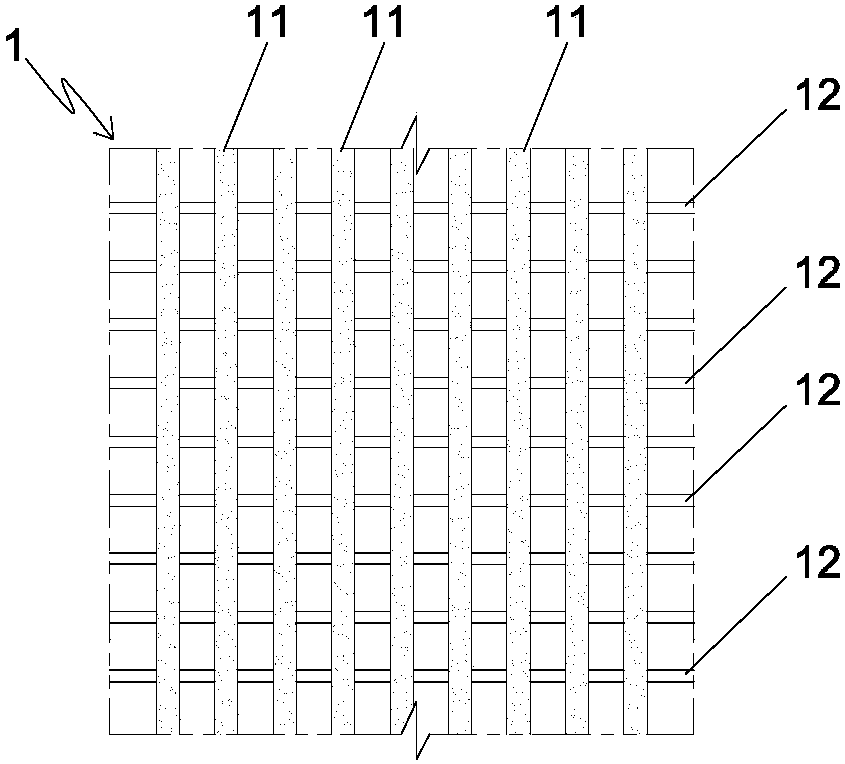

[0037] 1. Sand planting step: take a number of warp yarns 11 and a number of weft yarns 12, and form a square grid structure 1 through the warp yarns 11 and weft yarns 12, then coat the square grid structure 1 with glue, and then sandblast emery to form an emery layer 13, the other side is a flat gauze layer 14;

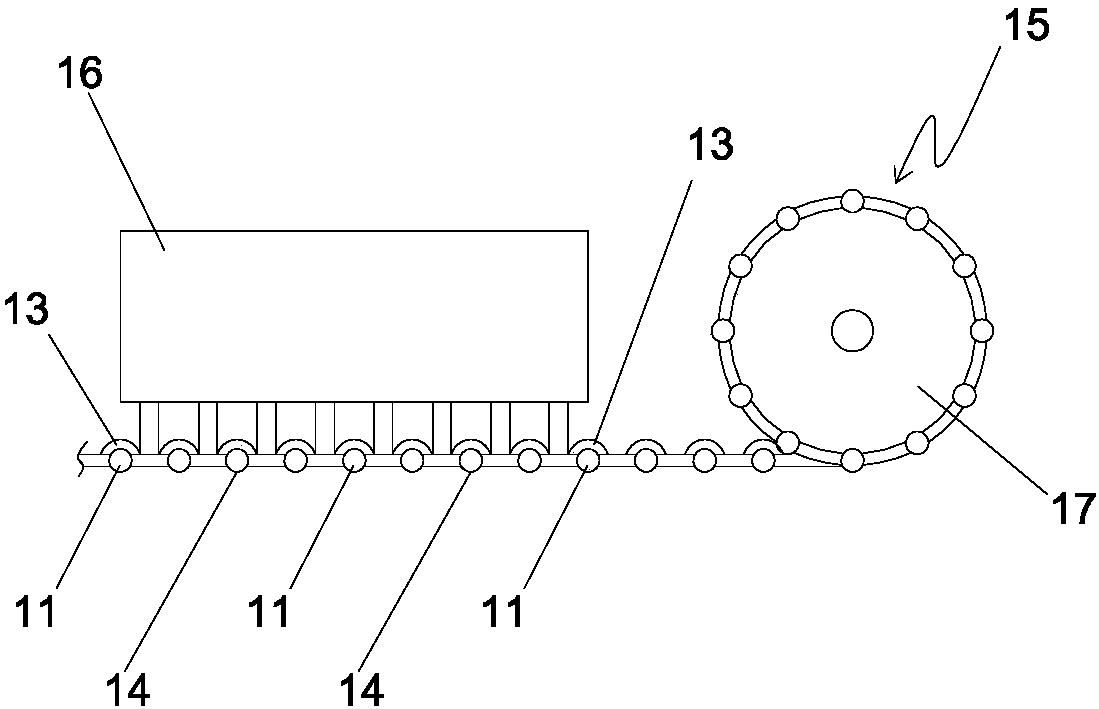

[0038] A desanding step: the emery layer 13 attached to the weft yarn 12 will be removed by the mold 16, leaving the emery layer 13 on the warp yarn 11 to form an emery gauze 15, and the emery gauze 15 is wound up in a reel 17, and has Emery layer 13 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com