Connecting structure of caisson and partition wall and construction method of connecting structure

A technology for connecting structures and construction methods, applied in the direction of walls, building components, building structures, etc., can solve the problems of high waterproof requirements, difficult to meet the waterproof requirements of toilets and adjacent rooms, etc., to improve the waterproof effect, enhance the application, The effect of increasing the space used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

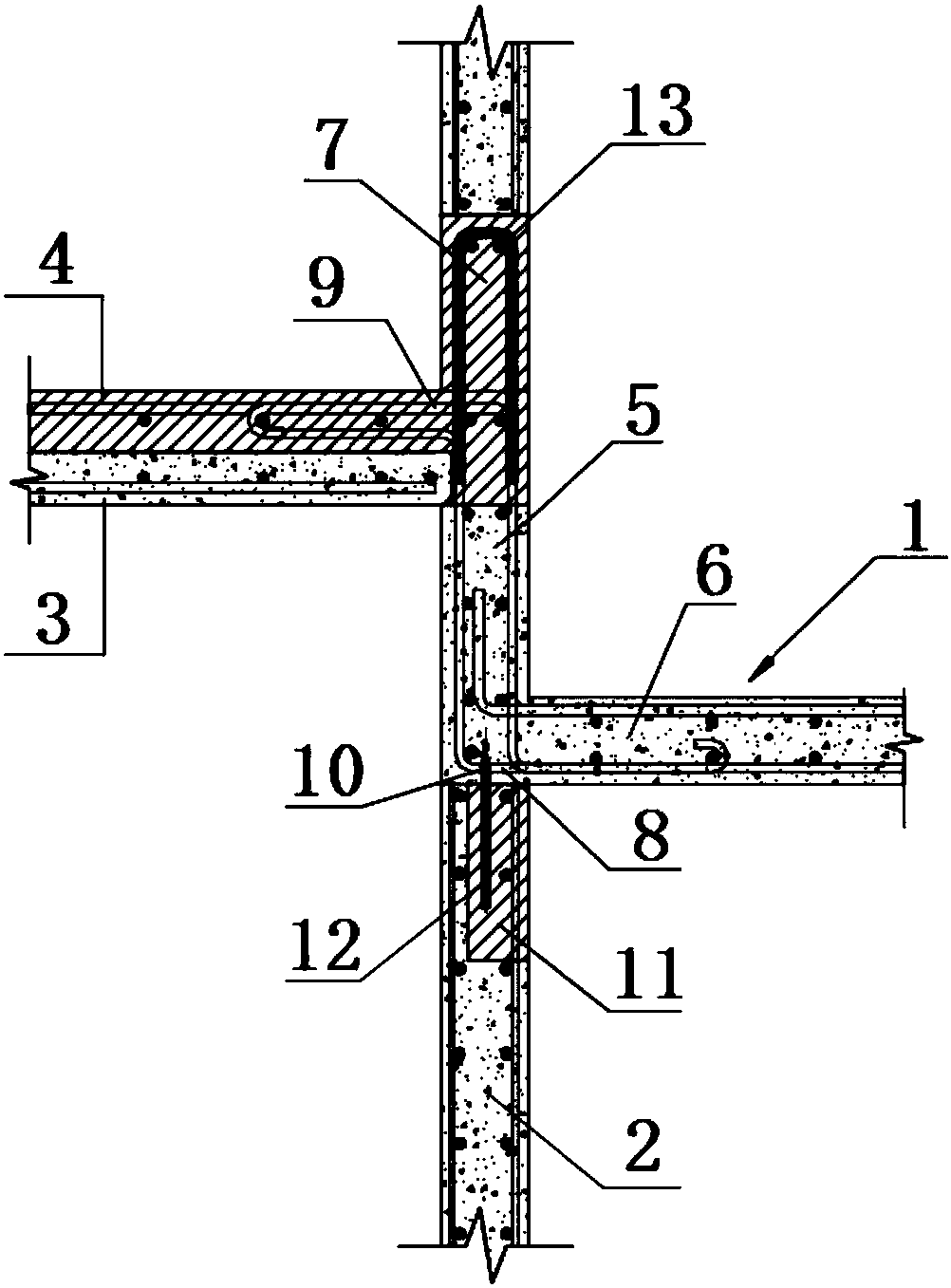

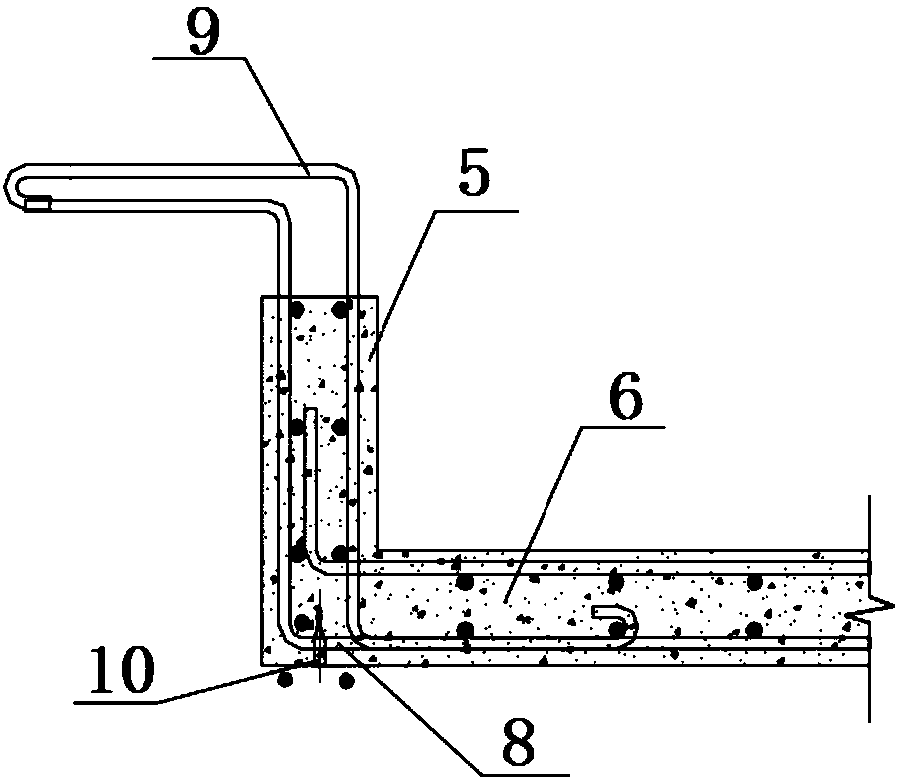

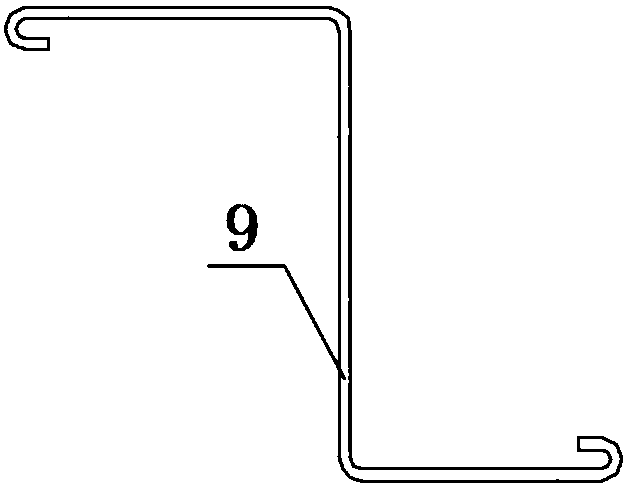

[0023] see Figure 1-2 The connection structure between the caisson and the partition wall includes a fully prefabricated caisson 1, a prefabricated partition wall 2 and a floor slab, the floor slab includes a prefabricated floor 3 and a cast-in-place floor 4, and the caisson 1 includes a side plate 5 and a bottom plate 6. The side plate 5 of the caisson 1 is in the same vertical plane as the prefabricated partition wall 2, and the end of the floor prefabricated layer 3 rests on the upper surface of the side plate 5 of the caisson 1, so A cast-in-place reverse sill 7 is provided above the floor in the vertical plane, and the cast-in-place reverse sill 7 and the floor slab cast-in-place layer 4 are integrally formed by cast-in-place, and the caisson 1 is also provided with a slab bottom Ribs 8 and additional slab gluten 9, the bottom slab 8 and the additional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com