Logistics tray

A pallet and logistics technology, which is applied in the field of logistics and transportation equipment, can solve the problems of logistics pallet scrapping, short service life of feet, long-term contact with the ground, etc., achieve good ventilation, increase the length of feet, and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

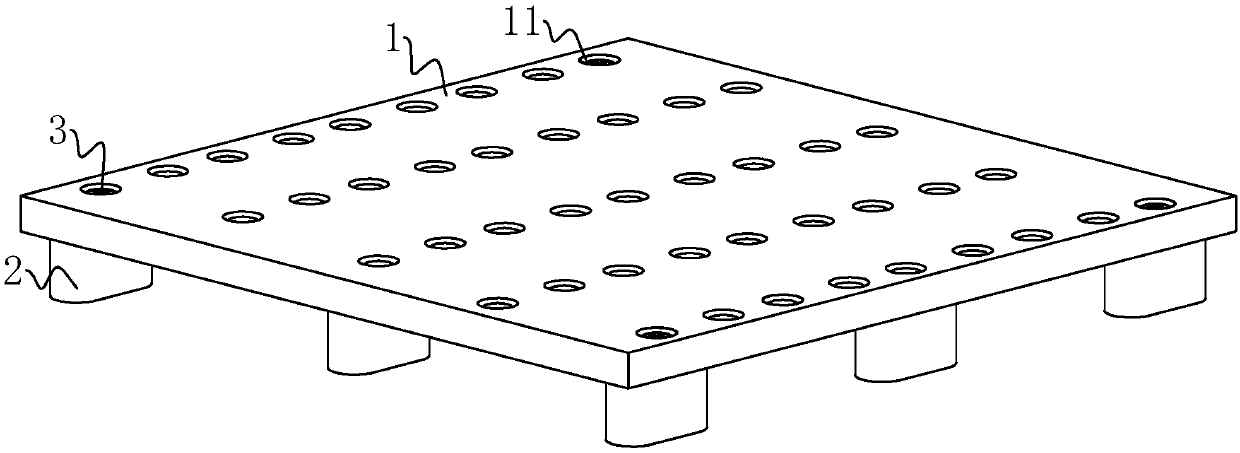

[0037] Embodiment 1: A logistics pallet, refer to figure 1 , including a disk surface 1, the disk surface 1 is a square plate structure, the upper and lower surfaces are horizontal, and both sides can be used as working surfaces. Disk 1 can be made of discarded mineral water bottles and other raw materials, so that the waste can be reused, saving natural resources while beautifying the environment; at the same time, both sides of disk 2 are treated with anti-skid treatment, and holes can be opened or anti-skid lines can be set.

[0038] A support foot 2 is detachably and fixedly connected to the bottom of the disk surface 1 . The current number of support feet 2 is 9, and the rectangular array is below the disk surface 2, so that the forklift can lift the logistics pallet from four directions, which is more convenient to use.

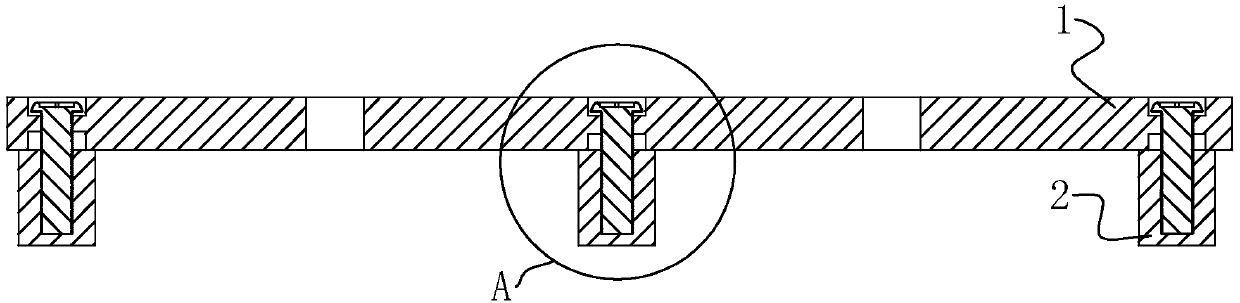

[0039] combine figure 2 , image 3 , the foot 2 is threadedly connected to the panel surface 1 through the connection assembly 3 . The connecting ...

Embodiment 2

[0041] Embodiment 2: the difference between this embodiment and embodiment 1 is that, refer to Figure 4 , in the actual use of the logistics pallet, the foot 2 often hits the ground, and the joint between the foot 2 and the connecting screw 31 will be deformed after the impact, which makes it more laborious to unscrew and screw in the connecting screw 31 in the later stage. posed difficulties.

[0042] To this end we inject a threaded sleeve 32 integrally during the injection molding of the foot 2 . The threaded sleeve 32 is made of metal material, and its inner ring is provided with an internal thread, which can be threadedly connected with the connecting screw 31 . The two ends of the threaded sleeve 32 do not pass through the support foot 2 , and its upper surface is flush with the support foot 2 plane. In order to make the connection between the threaded sleeve 32 and the support foot 2 more stable, the outer ring of the threaded sleeve 32 can be roughened, and a simple...

Embodiment 3

[0044] Embodiment 3: The difference between this embodiment and Embodiment 2 is that a height adjustment member is provided at the bottom of the leg 2 .

[0045] In order to reduce the footprint of the logistics tray when the logistics tray is processed, the height of the legs 2 is designed to be about 10cm. On the one hand, this height is not convenient for forklifts to quickly fork, and on the other hand, it is not convenient for the ventilation of the items on the logistics pallet.

[0046] For this reason we have designed a kind of height-adjusting part, is used for adjusting the height of support foot 2. Specifically, the height of the support foot 2 is still set at about 10 cm, and a threaded hole is vertically upwardly provided at the bottom of the connecting screw 31, and the height-adjusting part is selected from the height-adjusting screw 41, and the height-adjusting screw 41 is screwed on the head in a downward manner. in the threaded hole.

[0047]During use, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com