Preparation method of hydrodewaxing catalysts as well as catalyst prepared by method and application of catalyst

A hydrodewaxing and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high gas yield, low base oil yield, and large loss of viscosity index, etc., to achieve The effect of high yield and high isomer selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present disclosure provides a method for preparing a hydrodewaxing catalyst, the preparation method comprising: a. First impregnating the molecular sieve-inorganic oxide carrier with a solution containing a hydrogenation active metal salt, followed by drying, roasting and reduction in sequence, A supported catalyst is obtained; wherein, the molecular sieve is a molecular sieve with a one-dimensional elliptical pore structure, and the minor axis of the one-dimensional elliptical pore structure is The major axis of the one-dimensional elliptical hole structure is b. impregnating the supported catalyst obtained in step a with an aqueous solution of a nitrogen-containing compound for a second time and drying to obtain a hydrodewaxing catalyst.

[0027] The inventors of the present disclosure unexpectedly found that the acid strength of some active centers of the hydrodewaxing catalyst can be changed by impregnating the aqueous solution of nitrogen-containing compounds...

specific Embodiment approach

[0031]According to a specific embodiment of the present disclosure, the preparation method of the molecular sieve-inorganic oxide carrier may be: mixing the molecular sieve with the matrix, extruding, drying and calcining. When forming by extrusion molding, an appropriate amount of extrusion aid and / or adhesive can be added, and then extruded. The type and amount of the extrusion aid and peptizer are well known to those skilled in the art, and will not be repeated here. The drying temperature is preferably 100-200°C, more preferably 120-150°C, and the drying time is preferably 1-20 hours, more preferably 2-10 hours. The calcination temperature is preferably 400-650°C, more preferably 500-600°C, and the calcination time is preferably 1-15 hours, more preferably 2-10 hours.

[0032] According to the present disclosure, the hydrogenation active metal salt can be soluble salt containing hydrogenation active metal commonly used in the art, for example, it can be selected from nitr...

Embodiment 1

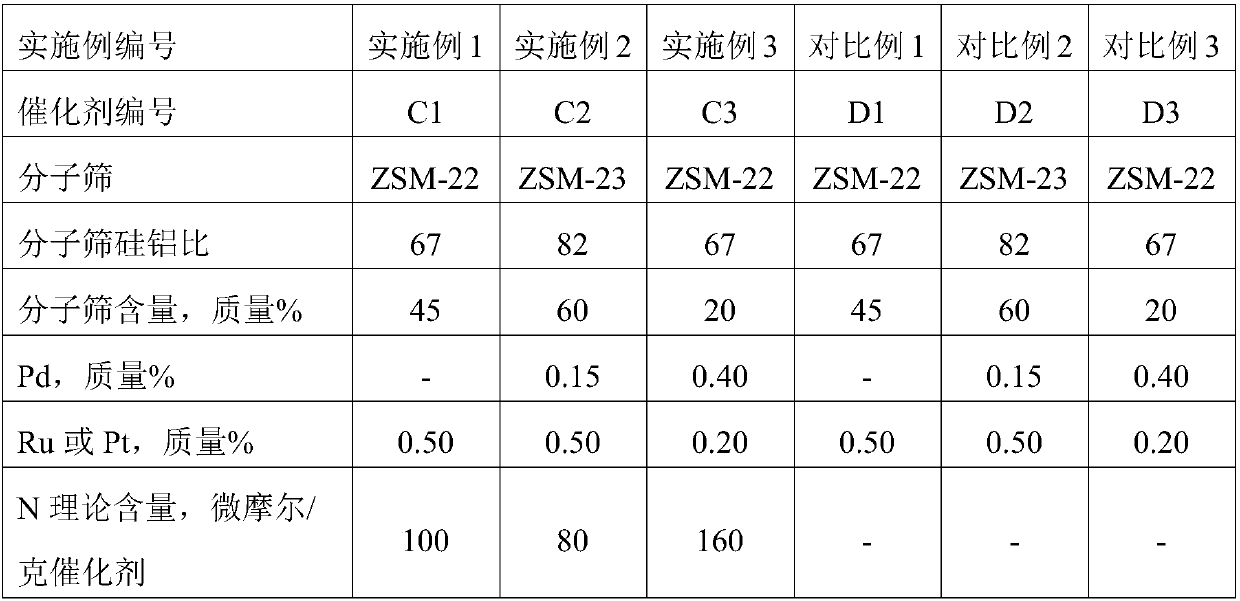

[0045] Catalysts provided by the present disclosure and methods for their preparation are described.

[0046] After mixing the organic template, the silicon source and the aluminum source, the crystallization was carried out in a stainless steel reaction kettle at 400 Rpm at 160° C. for 96 hours to obtain 100% ZSM-22 molecular sieve. Among them, the organic template is ethyl pyridinium bromide, and the aluminum source is Al 2 (SO 4 ) 3 ·16H 2 O, the silicon source is silica sol (SiO 2 Content is 30% by weight), the SiO of feeding 2 / Al 2 o 3 60, H 2 O / SiO 2 40,OH - / SiO 2 0.3, K + / SiO 2 is 0.43, template / SiO 2 The silicon-aluminum molar ratio of ZSM-22 molecular sieve is 67. Gained molecular sieve 100 grams to contain 20% by weight NH 4 NO 3 1000 ml of the solution was treated at 80° C. for 4 hours, filtered, and treated 3 times in total by the above method. The treated molecular sieves were dried at 120° C. for 4 hours. The hydrogen ZSM-22 molecular sieve w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com