Dental implant with porous thread structure

A technology for dental implants and porous bodies, which is used in dentistry, dental implants, dental prosthetics, etc., can solve the problems of affecting the long-term stability of the implants, the occlusal force cannot be uniformly transmitted, and the local stress of the implants is high, so as to eliminate the stress. Shielding phenomenon, improving implantation effect, enhancing implantation stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

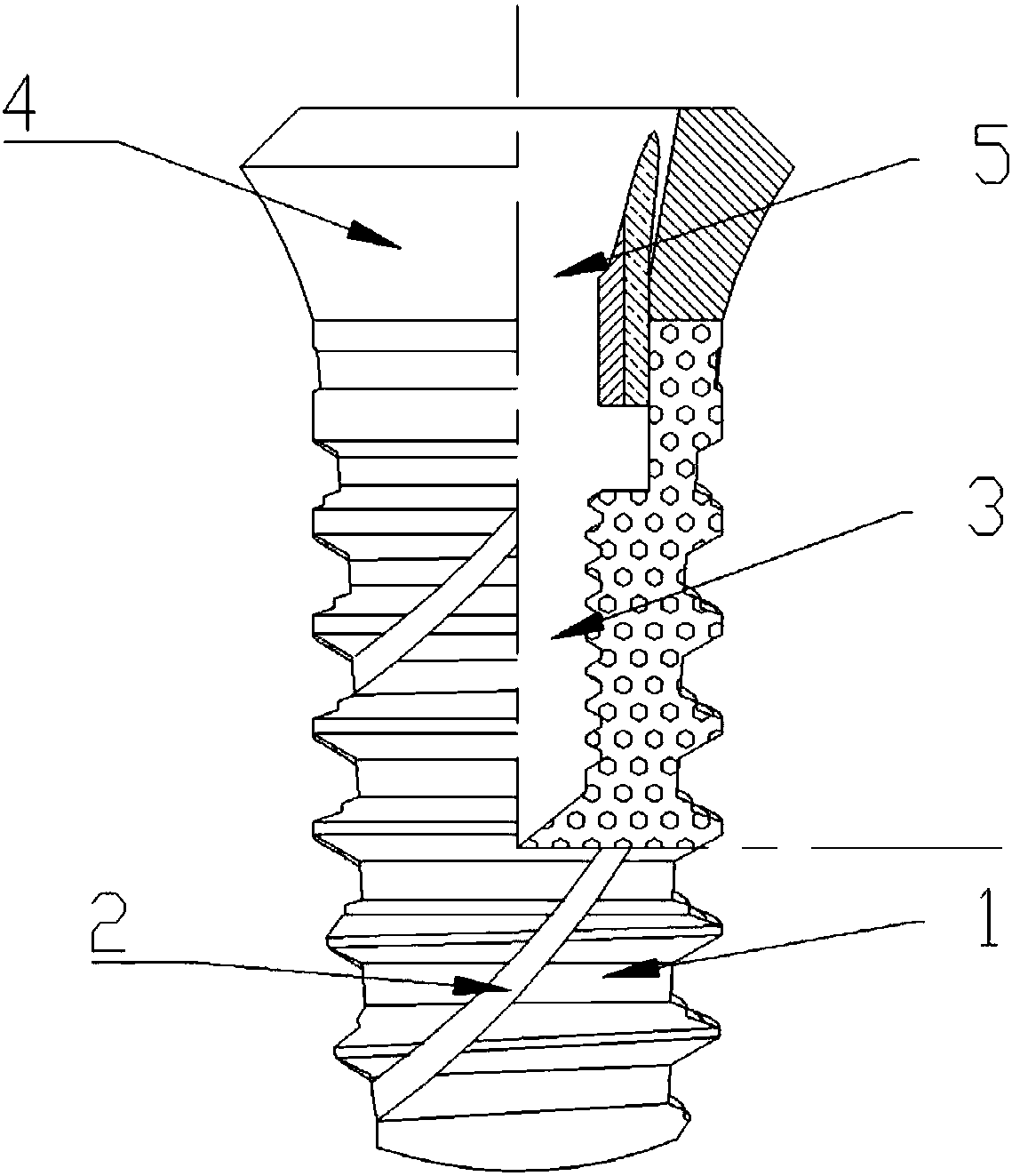

[0024] Such as figure 1 As shown, the dental implant with porous thread structure in this embodiment is made of pure titanium, and includes a body 1, which is provided with a thread, and the thread is provided with an edge groove 2, and the edge groove 2 is a helical edge. Groove, the central position of the middle and upper part of the body 1 is provided with a conical bottom threaded hole 3, the body 1 is a porous body, the porosity of the porous body is 5%, and there are multiple micropores on the porous body, The diameter of the micropores is 200 μm, and some of the micropores are interconnected to form three-dimensional through holes, such as figure 2 As shown, the total volume of the three-dimensional through holes on the porous body is 30% of the total volume of the micropores on the porous body.

[0025] The dental implant with a porous thread structure in this embodiment is prepared by a laser selective melting method.

[0026] The dental implant implant with porou...

Embodiment 2

[0028] Such as figure 1 As shown, the dental implant with a porous thread structure in this embodiment is made of pure tantalum, and includes a body 1, which is provided with a thread, and the thread is provided with an edge groove 2, and the edge groove 2 is a helical edge. Groove, the central position of the middle and upper part of the body 1 is provided with a conical bottom threaded hole 3, the body 1 is a porous body, the porosity of the porous body is 20%, and the porous body has a plurality of micropores, The pore diameter of the micropores is 500 μm, some of the micropores in the plurality of micropores are interconnected to form three-dimensional through holes, and the total volume of the three-dimensional through holes on the porous body is 80% of the total volume of the micropores on the porous body .

[0029] The dental implant with a porous thread structure in this embodiment is prepared by a laser selective melting method.

[0030] The dental implant implant w...

Embodiment 3

[0032] Such as figure 1 As shown, the dental implant implant with porous thread structure in this embodiment is made of Ti6Al4V titanium alloy, and includes a body 1. The body 1 is provided with a thread, and the thread is provided with an edge groove 2, and the edge groove 2 is straight. The edge groove, the central position of the middle and upper part of the body 1 is provided with a conical bottom threaded hole 3, the body 1 is a porous body, the porosity of the porous body is 10%, and there are multiple micropores on the porous body , the pore diameter of the micropores is 350 μm, some of the micropores in the plurality of micropores communicate with each other to form three-dimensional through holes, and the total volume of the three-dimensional through holes on the porous body is 60% of the total volume of the micropores on the porous body %.

[0033] The dental implant with a porous thread structure in this embodiment is prepared by an electron beam selective melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com