Three-terminal magnetic random access memory and reading and writing method thereof

A technology of random access memory and read-write method, which is applied in the direction of static memory, digital memory information, information storage, etc., can solve the problems of low signal resolution ability and reduce the signal resolution ability of storage units, etc., achieve great application prospects and improve signal resolution ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

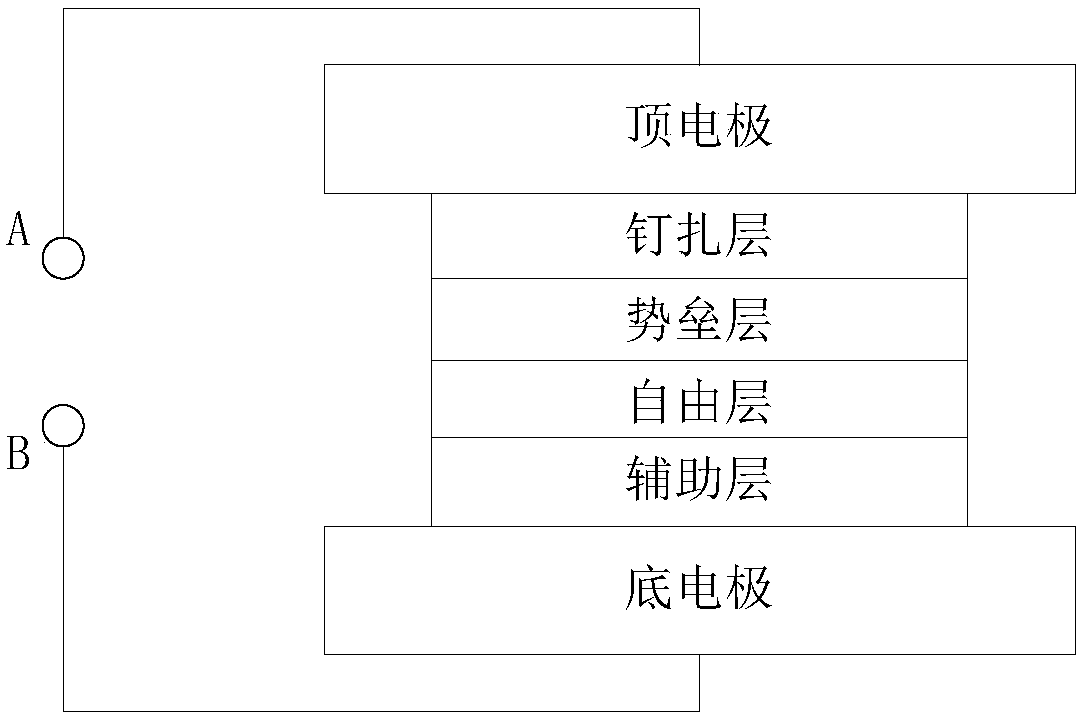

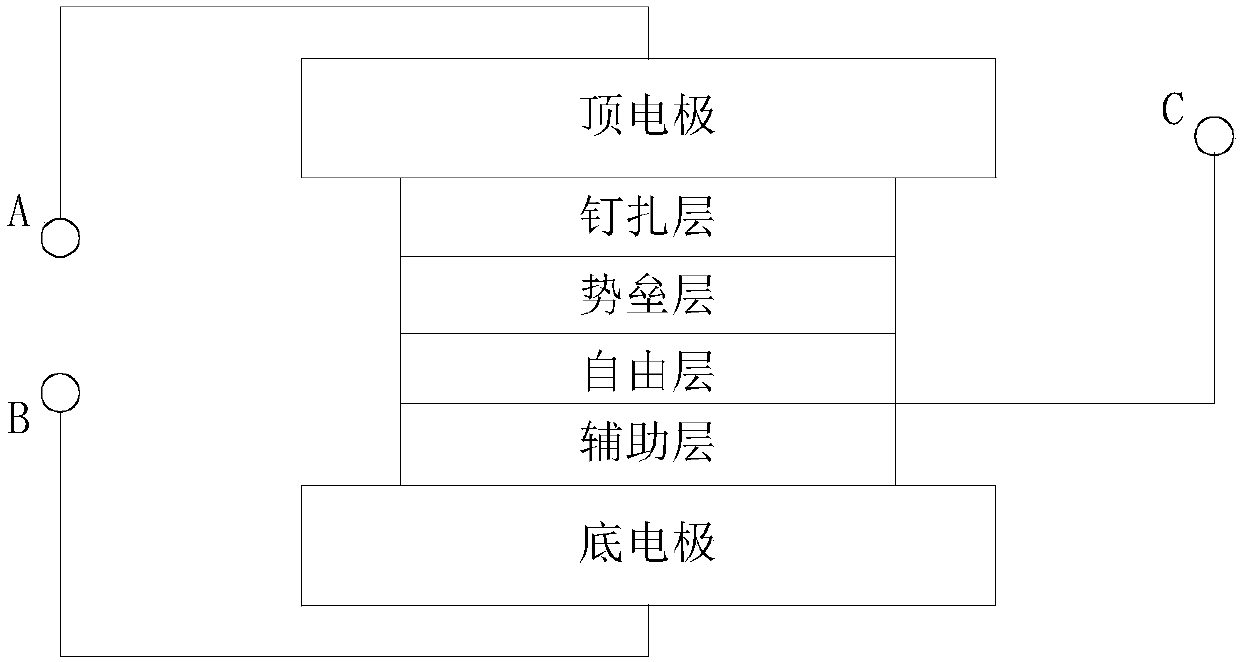

[0023] like Figure 2a As shown, the bottom electrode, auxiliary layer, free layer, barrier layer, pinning layer and top electrode are sequentially deposited on the silicon wafer (substrate) that has been prepared for the front-end process. On the free layer, a third terminal C is drawn out from the side that is in contact with the auxiliary layer. The magnetization direction of the pinned layer is fixed perpendicular to the film plane, and the magnetization direction of the free layer is variable.

[0024] By applying an electric field at the A and B terminals to change the magnetization direction of the free layer, the writing and erasing functions of the memory cell are realized. The resistance value of the memory cell is read by applying an electric field at the A and C terminals.

Embodiment 2

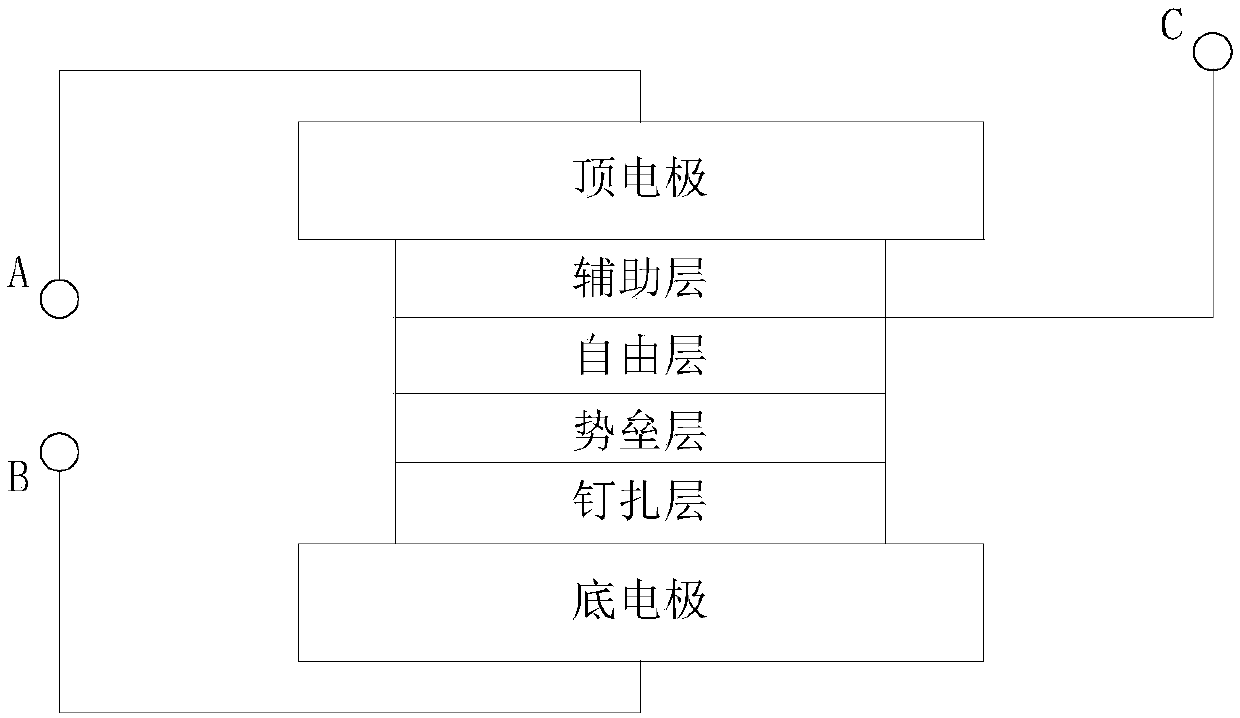

[0026] The order of the individual layers of the STT-MRAM stack can be reversed, as Figure 2b As shown, on the free layer, a third terminal C is led out from the side in contact with the auxiliary layer, and its properties have not changed. By applying an electric field at the A and B terminals to change the magnetization direction of the free layer, the writing and erasing functions of the memory cell are realized. The resistance value of the memory cell is read by applying an electric field at the B and C terminals.

Embodiment 3

[0028] like Figure 3a As shown, the difference from Embodiments 1 and 2 is that the magnetization direction of the pinned layer is fixed by the coupling between the antiferromagnetic coupling layer and the pinned layer. The bottom electrode, the auxiliary layer, the free layer, the barrier layer, the pinning layer, the antiferromagnetic coupling layer, the fixed layer and the top electrode are sequentially deposited on the silicon wafer that has been prepared for the front-end process. The magnetization direction of the pinned layer is fixed perpendicular to the film plane, and the magnetization direction of the free layer is variable. Likewise, on the free layer, a third terminal C is led out from the side that is in contact with the auxiliary layer. By applying an electric field at the A and B terminals to change the magnetization direction of the free layer, the writing and erasing functions of the memory cell are realized. The resistance value of the memory cell is read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com