Source drain variable-resistance rectangular grid controlled U-shaped channel bidirectional transistor and production method thereof

A rectangular gate, source-drain technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems that the sub-threshold swing cannot be reduced, and ordinary tunneling field effect transistors can only be used as one-way switches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further explained below in conjunction with the drawings:

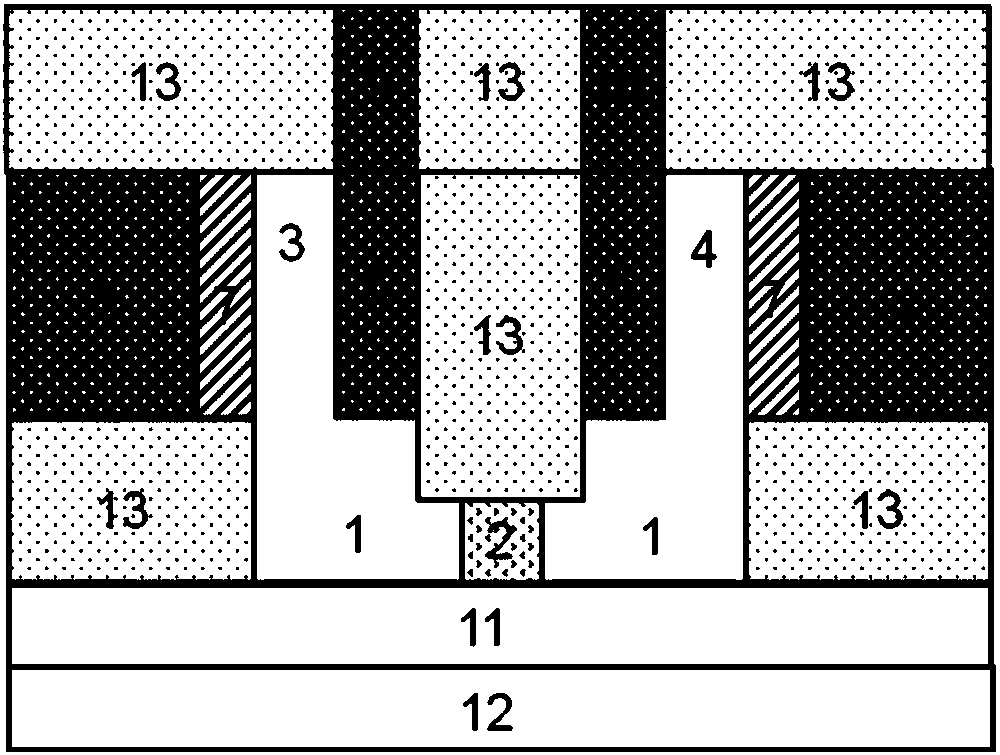

[0070] Such as figure 1 , figure 2 with image 3 As shown, a source-drain resistance variable rectangular gated U-shaped channel bidirectional transistor including a silicon substrate 12 of an SOI wafer is characterized in that: the silicon substrate 12 of the SOI wafer is above the substrate of the SOI wafer Insulating layer 11, above the insulating layer 11 of the substrate of the SOI wafer is a part of the monocrystalline silicon film 1, the heavily doped region 2 and the insulating dielectric barrier layer 13. Among them, the monocrystalline silicon film 1 has an impurity concentration lower than 10 16 cm -3 The single crystal silicon semiconductor material; the heavily doped region 2 is located in the middle part of the bottom of the single crystal silicon film 1, and its doped impurity conductivity determines the conduction type of the device, and its interior is not controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com