Needling production process for preparing wool-like knitted fabric from wool-like filaments

A production process and wool-like needle technology, which is applied in the field of textile and weaving to achieve the effects of improving production efficiency, reducing unqualified product quality and softening the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

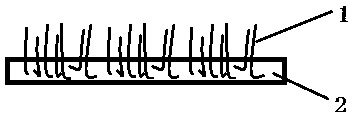

Image

Examples

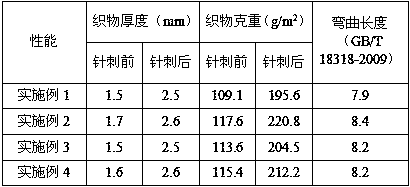

Embodiment 1

[0020] A needle punching production process for preparing wool-like knitted fabrics through wool-like silk, comprising the following steps:

[0021] (1) Using wool-like silk as raw material, it is woven with a weft knitting 1+1 double rib weave structure through a large circular machine to obtain a base fabric, in which one yarn of the rib weave is 75D / 72F polyester DTY untwisted yarn, and the other The root yarn is 120D / 144F viscose long fiber untwisted yarn, and the average length of the loops of the rib weave is 3cm;

[0022] (2) Fix the base fabric on the pre-acupuncture machine, lay the net on the front side of the base fabric and stack the short fiber layer, and perform front-side pre-acupuncture. The depth of pre-acupuncture is 4 cm, and the frequency of pre-acupuncture is 10 times / s. Short fiber is that the mass ratio of wool fiber and polyester fiber is 2:95, and the average fiber length is 4mm, and the diameter of polyester fiber is 3um;

[0023] (3) Send the base f...

Embodiment 2

[0026] A needle punching production process for preparing wool-like knitted fabrics through wool-like silk, comprising the following steps:

[0027] (1) Using wool-like silk as raw material, it is woven with a weft knitting 2+2 double rib weave structure through a large circular machine to obtain a base fabric, in which the rib weave is 200D / 288F polyester DTY untwisted yarn and 150D / 288F viscose long fiber The untwisted yarns are arranged side by side, and the average length of the ribbed loops is 4.5cm;

[0028] (2) Fix the base fabric on the pre-acupuncture machine, lay the net on the front of the base fabric and stack the short fiber layer, and perform front pre-acupuncture. The depth of pre-acupuncture is 7 cm, and the frequency of pre-acupuncture is 5 times / s. The short fiber is that the mass ratio of viscose staple fiber and rabbit hair fiber is 95:5, the average fiber length is 8mm, and the diameter of viscose staple fiber is 5um;

[0029] (3) Send the base fabric int...

Embodiment 3

[0032] A needle punching production process for preparing wool-like knitted fabrics through wool-like silk, comprising the following steps:

[0033] (1) Using wool-like silk as raw material, it is woven with a weft knitting 2+2 double rib weave structure through a large circular machine to obtain a base fabric, in which the rib weave is 100D / 168F polyester DTY untwisted yarn and 150D / 132F polyester DTY untwisted yarn The wires are arranged in phase, and the average length of the coils of the ribbed structure is 4cm;

[0034] (2) Fix the base fabric on the pre-acupuncture machine, lay the net on the front of the base fabric and stack the short fiber layer, and perform front pre-acupuncture. The depth of pre-acupuncture is 5 cm, and the frequency of pre-acupuncture is 8 times / s. The short fiber is polyester DTY untwisted yarn and the mass ratio of wool fiber is 95:5, the mass ratio of wool fiber wool and rabbit hair is 1:1, the average length of the fiber is 6mm, and the diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coil length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com