Bending method and processing equipment for connecting piece

A technology for processing equipment and connectors, which is applied in the field of bending methods and processing equipment for connectors, can solve problems such as horizontal deviation of connectors, failure to meet product processing requirements, and unsatisfactory processing accuracy, so as to ensure bending effect, anti-deformation, soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

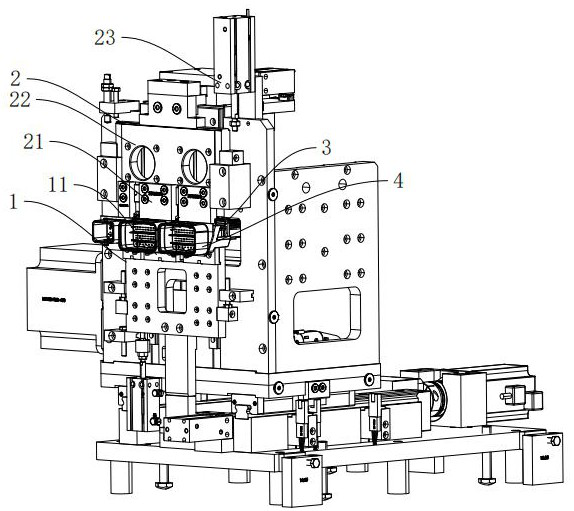

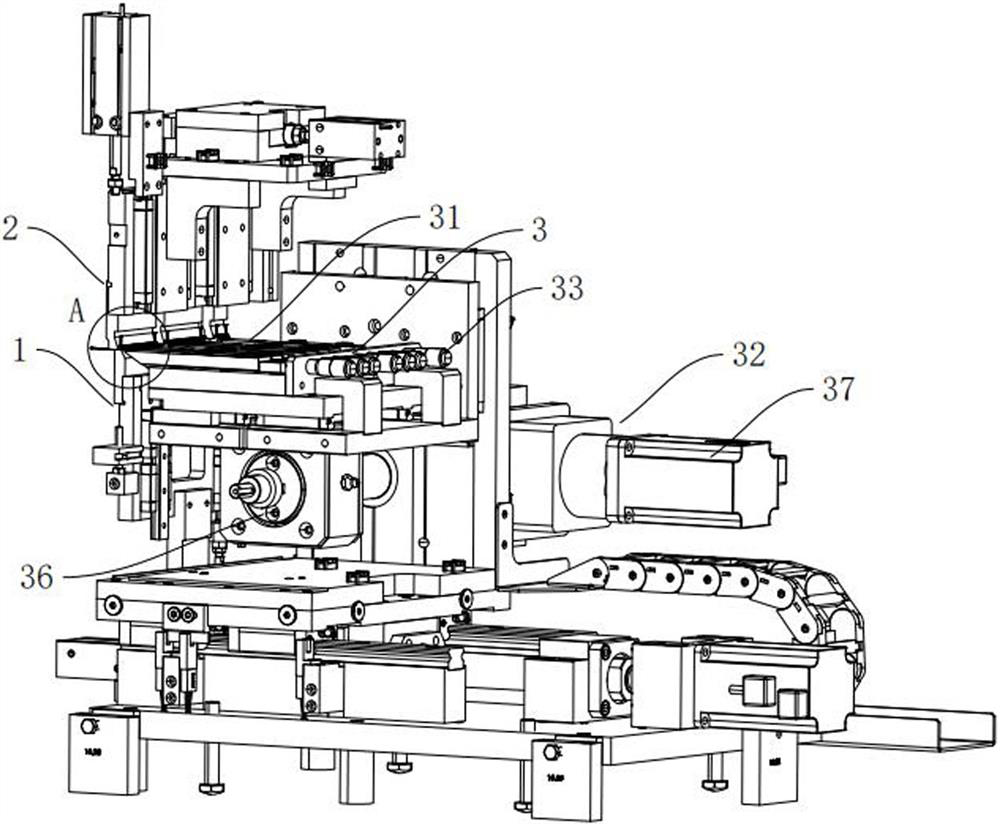

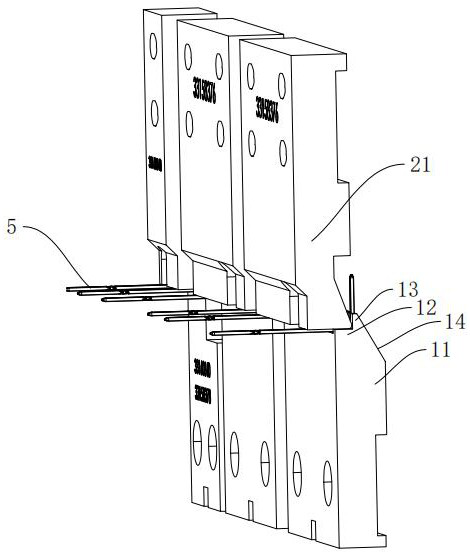

[0036] Embodiment one: see Figure 1-7 Shown, a kind of bending method of connector, comprises:

[0037] A plurality of connectors 5 are arranged at intervals along the X-axis direction, wherein the outer circumference of the fixing portion of the connectors 5 is fixed, and the preset bending portion of the connectors 5 is defined along the X-axis direction, And the force-bearing part at the end of the preset bending part away from the fixed part is suspended in the air;

[0038] A first bending force along the Y-axis direction acts on the force-receiving part, so that the preset bending part is bent around the fixed part and the preset bending part in a vertical plane perpendicular to the X-axis direction The bending point between the parts is rotated so as to form a first bending angle between the fixed part and the preset bending part;

[0039] A second bending force parallel to the extension direction of the connecting piece 5 acts on the force-receiving part, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com