Test research device used for electrical performance research on mixed gas of high-voltage electrical equipment

A technology of equipment mixing and high-voltage electrical appliances, which is applied in the direction of testing dielectric strength, can solve the problems that the mixed gas insulation gap breakdown characteristics cannot be used to study the mixed gas arc research, and achieve the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

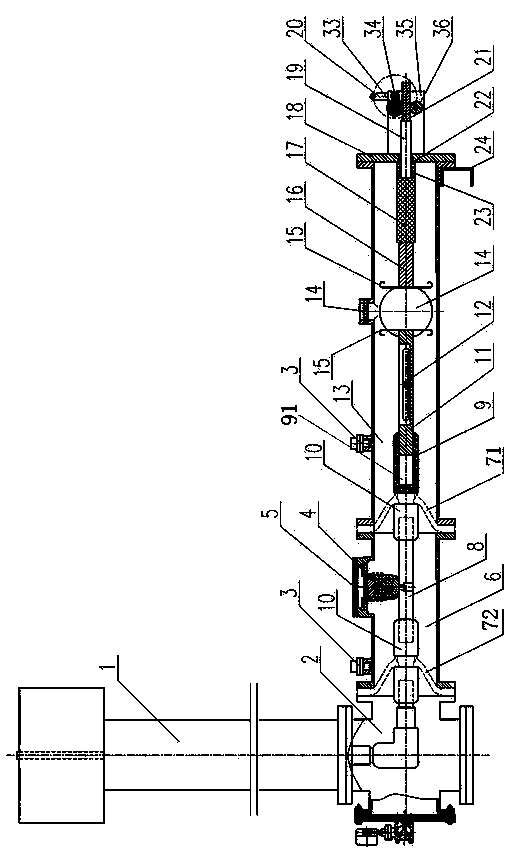

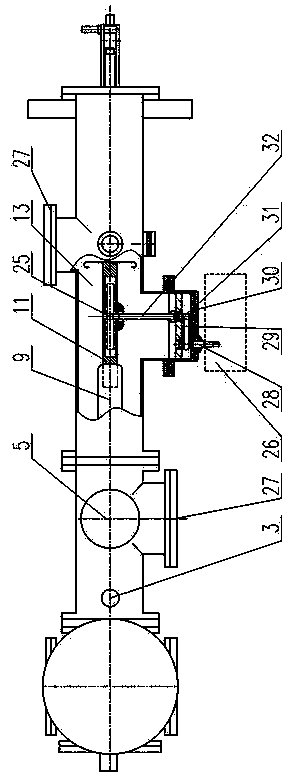

[0021] Embodiment 1 of the present invention, as Figure 1-2 Shown: The test and research device used for the research on the electrical performance of the mixed gas of high-voltage electrical equipment. It also includes a lead end air chamber 2 connected to the high voltage bushing 1, the lead end air chamber 2 is arranged at the lower end of the high voltage bushing 1, the lead end air chamber 2 is connected with a horizontally arranged cylinder, and the cylinder is separated by a pot insulator into The first test air chamber 6 and the second test air chamber 13, the first test air chamber 6 is adjacent to the lead end air chamber 2, the air pressure in the lead end air chamber 2 is constant, not used for testing, the first test air chamber 6 and the second test air chamber Two test chambers 13 are available for testing. The lead terminal gas chamber 2 is separated from the first test gas chamber 6 by the second basin-type insulator 72, and the first test gas chamber 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com