Levigated jeans cloth sizing process moulding and producing method thereof

A denim and manufacturing method technology, applied in the field of handicrafts, can solve the problems of complex production, low firmness and high cost, and achieve the effects of low raw material cost, simple production method and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

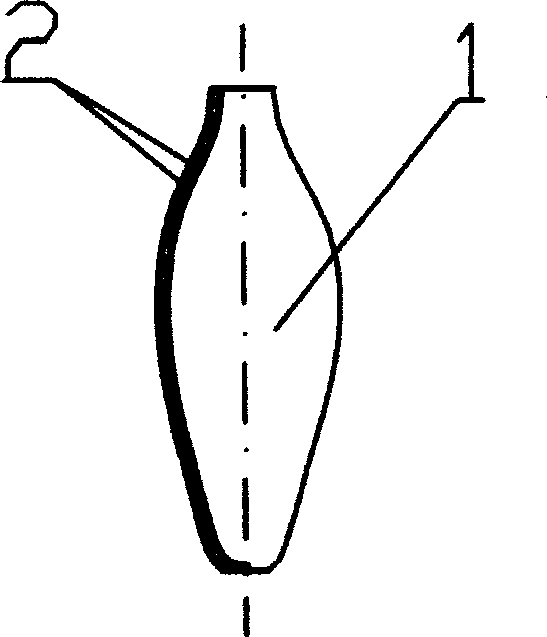

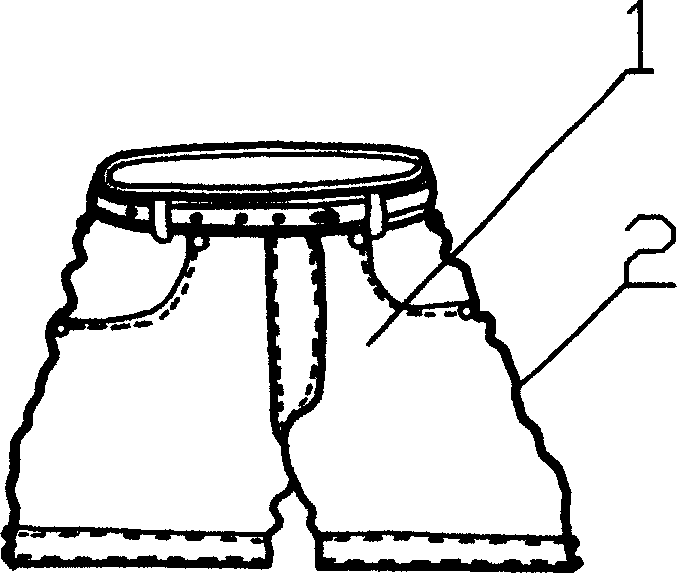

[0016] The water-milled denim craft shape includes a hollow water-milled denim pulp craft shape 1 with an opening, and a sizing glue 2 is provided on the inner and outer walls of the water-milled denim craft shape.

Embodiment 2

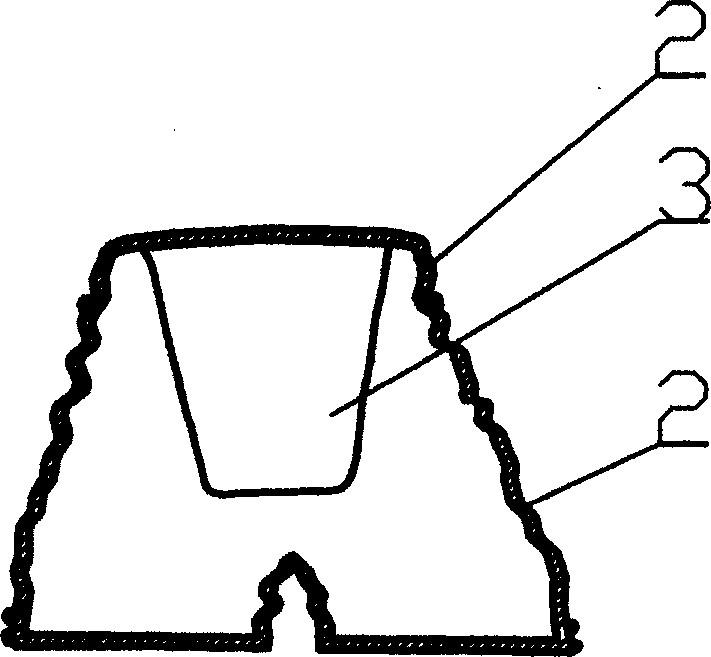

[0018] An open container 3 is fixed at the opening of the inner cavity of the water-milled denim slurry craft molding, and the container 3 is cemented in the craft molding, and when the vase is used, it can bear and hold earth.

[0019] Craft modeling 1 is made of cotton cloth or linen, which can be made into various appearance shapes, such as vases, containers, or combined into various craft shapes such as figures, animals, handicrafts, etc., which can be widely used for decoration, or as containers. For planting flowers and plants or placing various decorations to increase the interest of life.

[0020] Water grinding denim pulp process modeling 1 manufacturing method is as follows: first cut the fabric according to the process modeling design, sew the cut fabric into a hollow craft shape with an opening, and then soak the sewn craft shape in the shaping glue for a few seconds to make the shaping glue Cover the inner and outer walls of the craft shape and shape it. Immediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com