Lightweight and high-strength wheat straw board of oriented structure

A straw board, high-strength technology, applied in the joint of wooden veneers, pretreatment of molding materials, household components, etc., can solve the problems of low added value, single function, traditional field, etc., and achieve the increase of section density, mechanical High performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

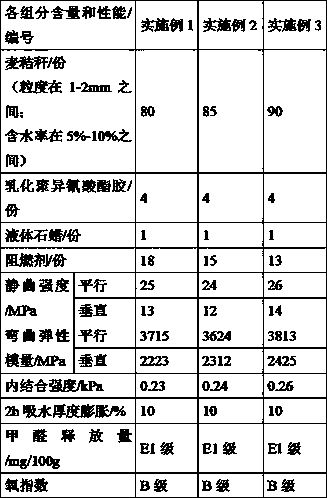

[0026] According to the components specified in Table 1 below, the wheat straw, emulsifiable polyisocyanate adhesive, liquid paraffin and nitrogen-phosphorus flame retardant were weighed in parts by weight. Dry the wheat straw in a drying oven at a temperature of 100-110°C for 1 hour until the moisture content is between 5% and 10%; cut the dried wheat straw into granules and put them into a grinder for grinding Grinding, the rotation speed is 150r / min, the grinding time is 0.5h; use a sieve to screen out the wheat straw powder with a particle size between 1-2mm; put the wheat straw powder into the drying box for drying, the temperature is 100-110°C, the drying time 0.5h, until the water content is between 5% and 10%; add the adhesive and liquid paraffin to the above-mentioned wheat straw powder, and stir evenly; put the evenly stirred wheat straw raw material on the double-steel belt continuous flat press machine Carry out criss-cross weaving pavement into a slab; fix the pol...

Embodiment 2

[0028] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

Embodiment 3

[0030] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

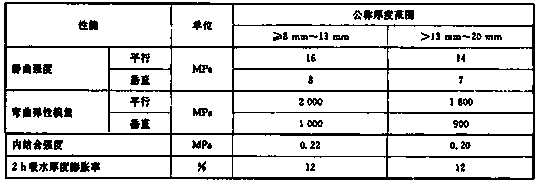

[0031] 1. Performance testing.

[0032] The specifications, appearance quality, and physical and mechanical properties of the finished products prepared in Examples 1-3 of the present invention are tested and judged according to the provisions of the national standard LYT 2141-2013 Oriented Structure Wheat Straw Board, and the detection is carried out according to the nominal thickness of 8mm. The amount of formaldehyde released is measured according to the national GB18580-2001; the flame retardant performance is tested according to GB8624-2006.

[0033] 1. The performance test of the novel roof insulation and waterproof material prepared in Examples 1-3, the results are shown in Table 1.

[0034] Table 1 The physical and chemical indicators of new roof insulation and waterproof materials.

[0035]

[0036] 2. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com