Automatic cleaning device of machine tool worktable

An automatic cleaning and workbench technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high labor intensity, slow cleaning speed, narrow slides, etc., to reduce labor intensity and clear speed. , the effect of beneficial to safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

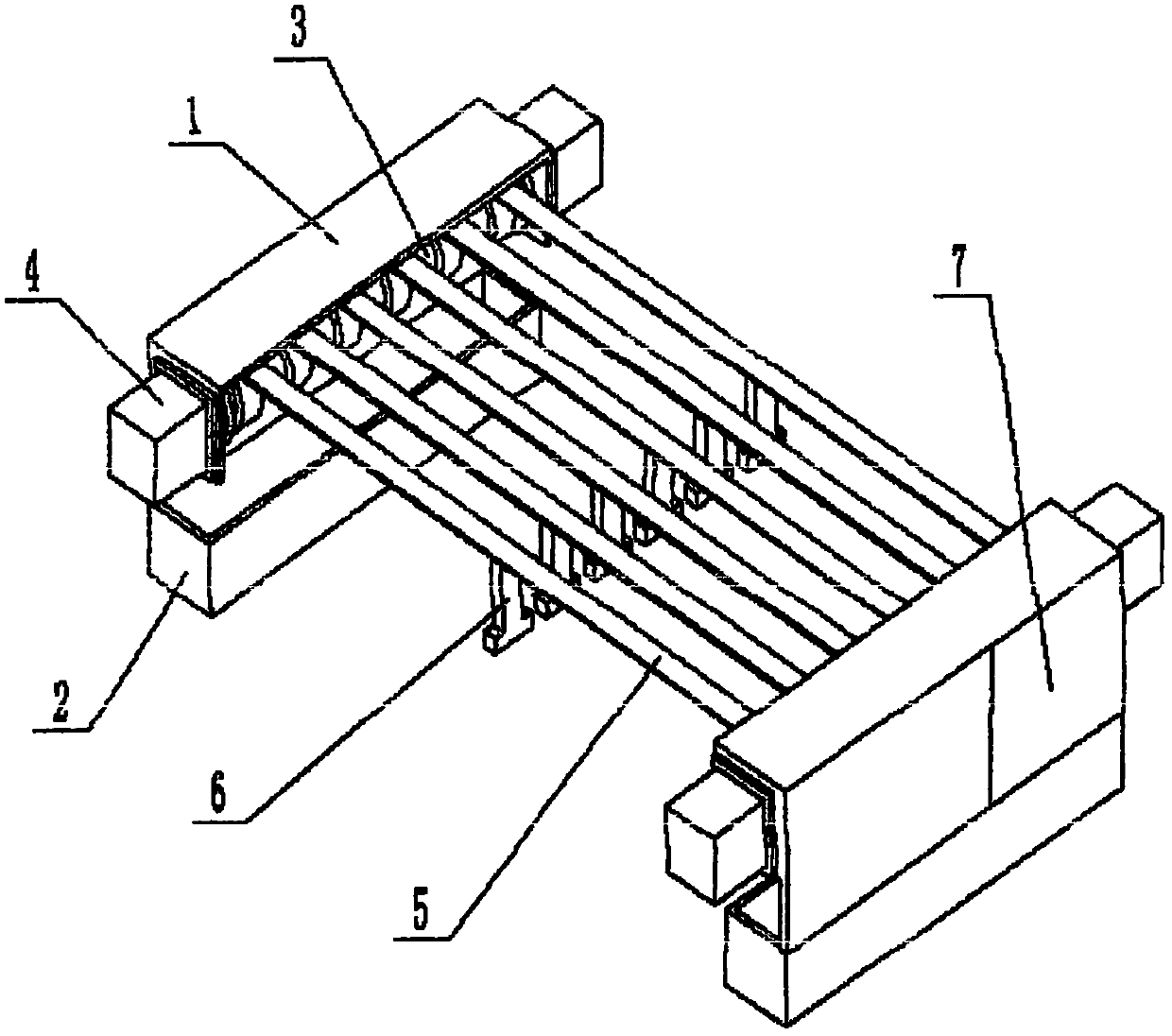

[0007] Referring to Figure 1, it includes a mounting frame 1, an iron scrap collection tank 2, a winding roller 3, a motor 4, a transmission belt 5, a brush head 6 and an operation panel 7, and the T-shaped brush head is clamped in the chute of the machine tool console, The iron filings collection tank 2 is fixedly connected to the bottom end of the mounting frame 1, the two ends of the rotating shaft of the winding roller 3 are flexibly connected to the mounting frame 1, and the end of the rotating shaft of the winding roller 3 is connected to the output shaft of the motor 4, and the motor 4 is installed At the front and back ends of the mounting frame 1; there are two mounting frame 1, iron scrap collection tank 2 and two winding rollers 3, the brush head 6 is connected to the lower surface of the transmission belt 5, and the two ends of the transmission belt 5 are wound on two winding rollers 3; the operation panel 7 is set on the outer wall of the installation frame 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com