Efficient paint spraying method for furniture

A furniture, high-efficiency technology, used in spray devices, devices for applying liquid to surfaces, pre-treatment surfaces, etc., can solve problems such as easy scattering in the air, low adhesion, slow drying speed, etc., to achieve good scratch resistance. , Less volatilization of paint, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

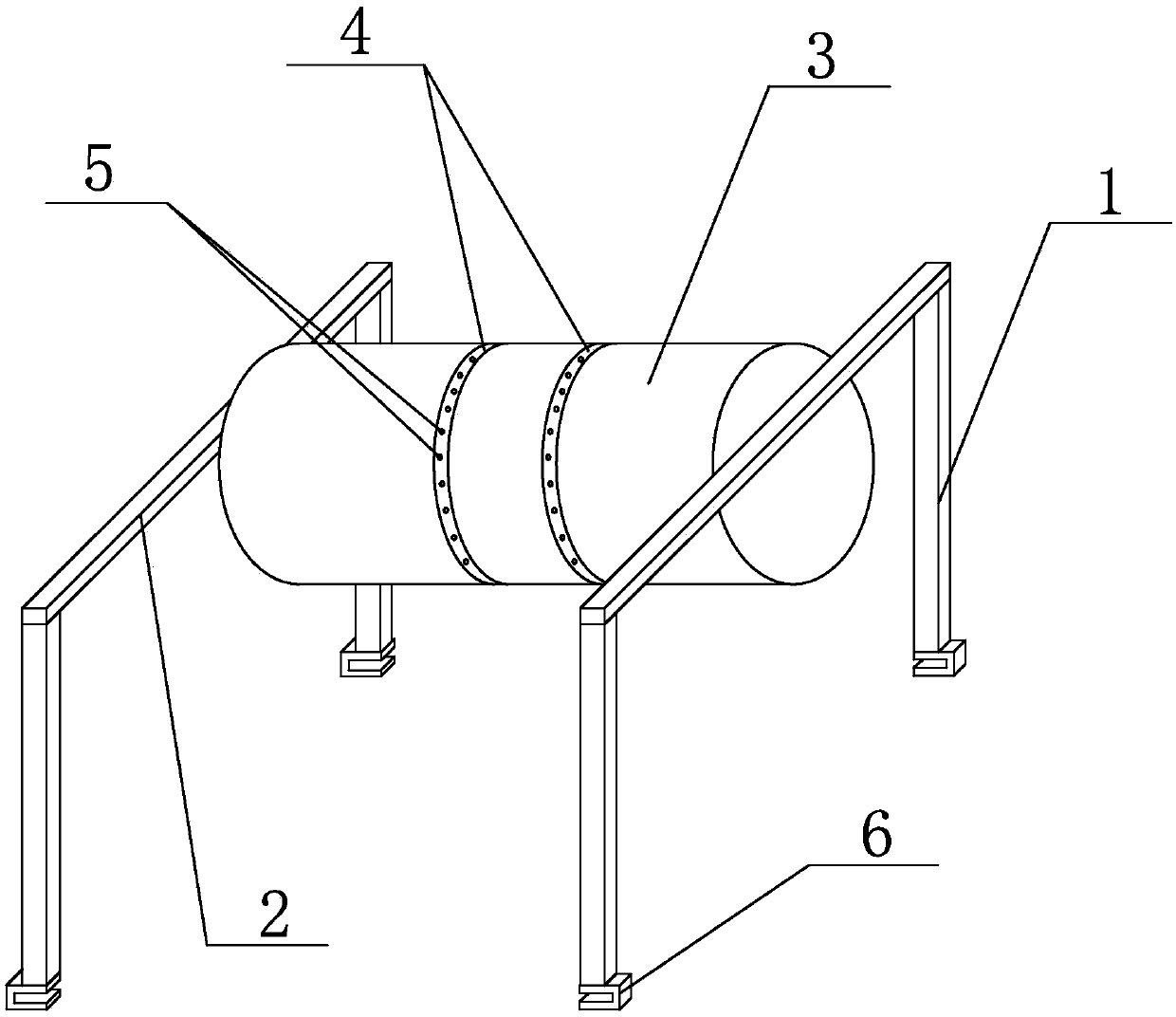

Image

Examples

Embodiment 1

[0022] A high-efficiency painting method for furniture of the present invention comprises the following steps: 1) placing the furniture in a sealed cabin, steaming for 10-15 minutes by high-temperature steam, and then taking it out and drying it in a drying room so that the moisture content of the wood is 6 %-11%; 2) Polish the dried furniture smooth with sandpaper; 3) Use high-pressure wind to sweep the polished furniture surface to remove dust and small particles, and brush the surface with a soft brush at the same time; 4) Then Put the furniture into the airtight cabin and steam it with high-temperature steam for 2-3 minutes; 5) Apply a layer of transparent primer on the surface of the furniture by using a spraying device, then irradiate and heat with ultraviolet light to cure the coated primer, and irradiate The time is 10-15min, and the heating temperature is 40-45°C; 6) Use fine sandpaper to polish the once-cured primer; 7) After polishing, the surface of the primer is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com