Carbon sphere/sulfur/reduced and oxidized graphene composite material for lithium sulfur battery and preparation method of carbon sphere/sulfur/reduced and oxidized graphene composite material

A composite material, lithium-sulfur battery technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of lithium-sulfur battery capacity and energy decline, achieve good application prospects, enhance rate performance and cycle stability performance , the effect of regulating the thickness of the pole piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a reduced graphene oxide / sulfur / carbon sphere composite material for lithium-sulfur batteries, the steps are as follows:

[0038] 1. Take 200ml of graphene oxide aqueous solution with a concentration of 5mg / ml, add 0.5g of conductive carbon black, ultrasonically disperse for 2 hours, and spray dry. The temperature is set at 150°C to obtain carbon spheres containing graphene oxide. After drying, place In a tube furnace, under argon protection, heat treatment at 500°C for 2 hours to obtain carbon spheres containing reduced graphene oxide.

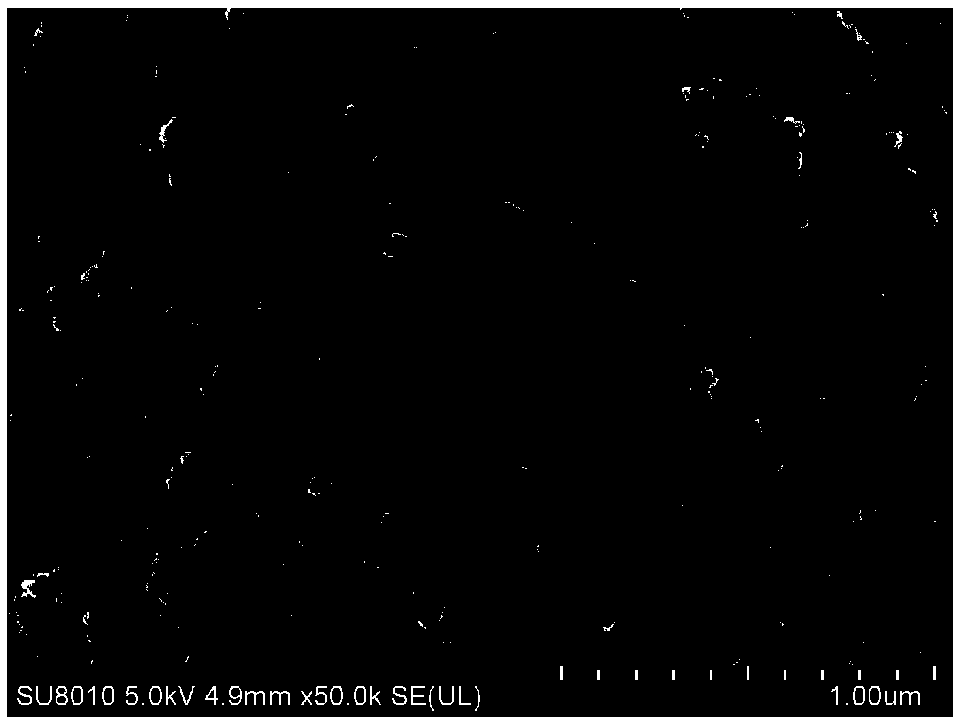

[0039] 2. Weigh 1g of the above-mentioned carbon spheres and mix them with 5g of sublimated sulfur, add a small amount of ethanol to disperse, ball mill for 1h, and vacuum dry at 55°C for 6h to obtain a sulfur / carbon sphere mixture. The scanning electron microscope of the sulfur / carbon sphere mixture is as follows: figure 2 shown by figure 2 It can be seen that sulfur is uniformly stored in the surface folds a...

Embodiment 2

[0046] A method for preparing a reduced graphene oxide / sulfur / carbon sphere composite material for lithium-sulfur batteries, the steps are as follows:

[0047] 1. Take 200ml of graphene oxide aqueous solution with a concentration of 5mg / ml, add 1.0g of conductive carbon black, ultrasonically disperse for 2 hours, and spray dry. The temperature is set at 155°C to obtain carbon spheres containing graphene oxide. After drying, place In a tube furnace, under argon protection, heat treatment at 500°C for 1 h to obtain carbon spheres containing reduced graphene oxide.

[0048] 2. Weigh 5g of sulfur powder, dissolve it in 500ml of carbon tetrachloride solution, and ultrasonicate for 2 hours to dissolve completely.

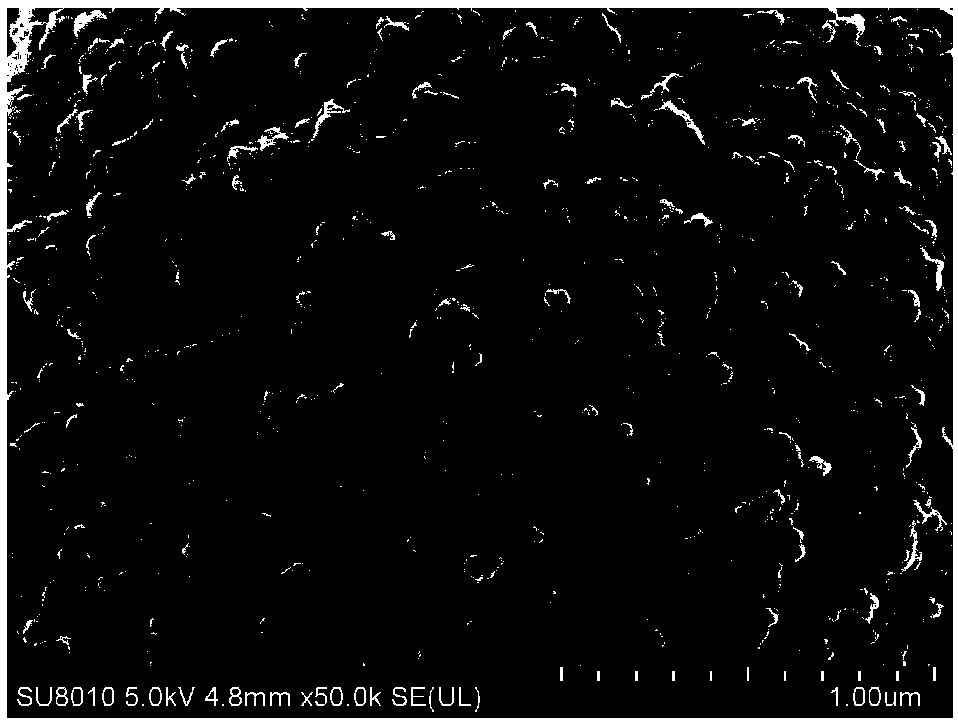

[0049] 3. Add 1 g of the above-prepared carbon spheres to the carbon tetrachloride solution, and rotatively evaporate at room temperature. After the carbon tetrachloride is naturally evaporated to dryness, the sulfur / carbon sphere composite is obtained, and dried in a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com